Self-emulsified polyester, preparation method of polyester as well as minimal quantity lubrication agent prepared from polyester

A self-emulsifying polyester, trace lubricant technology, applied in lubricating compositions, base materials, petroleum industry, etc., can solve problems such as environmental impact, achieve good lubricity, reduce harm to the environment and workers, and reduce pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

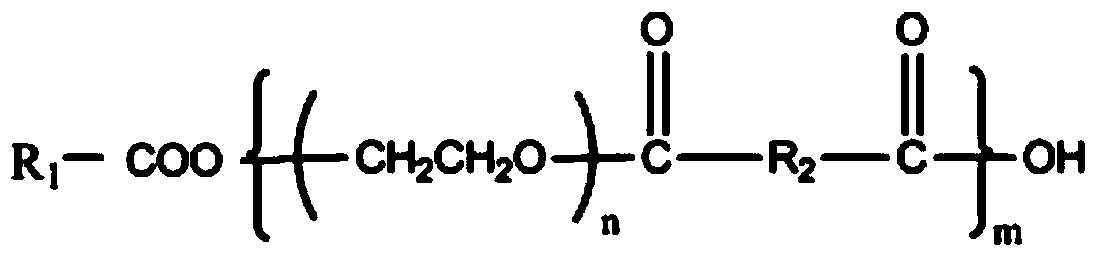

AI Technical Summary

Problems solved by technology

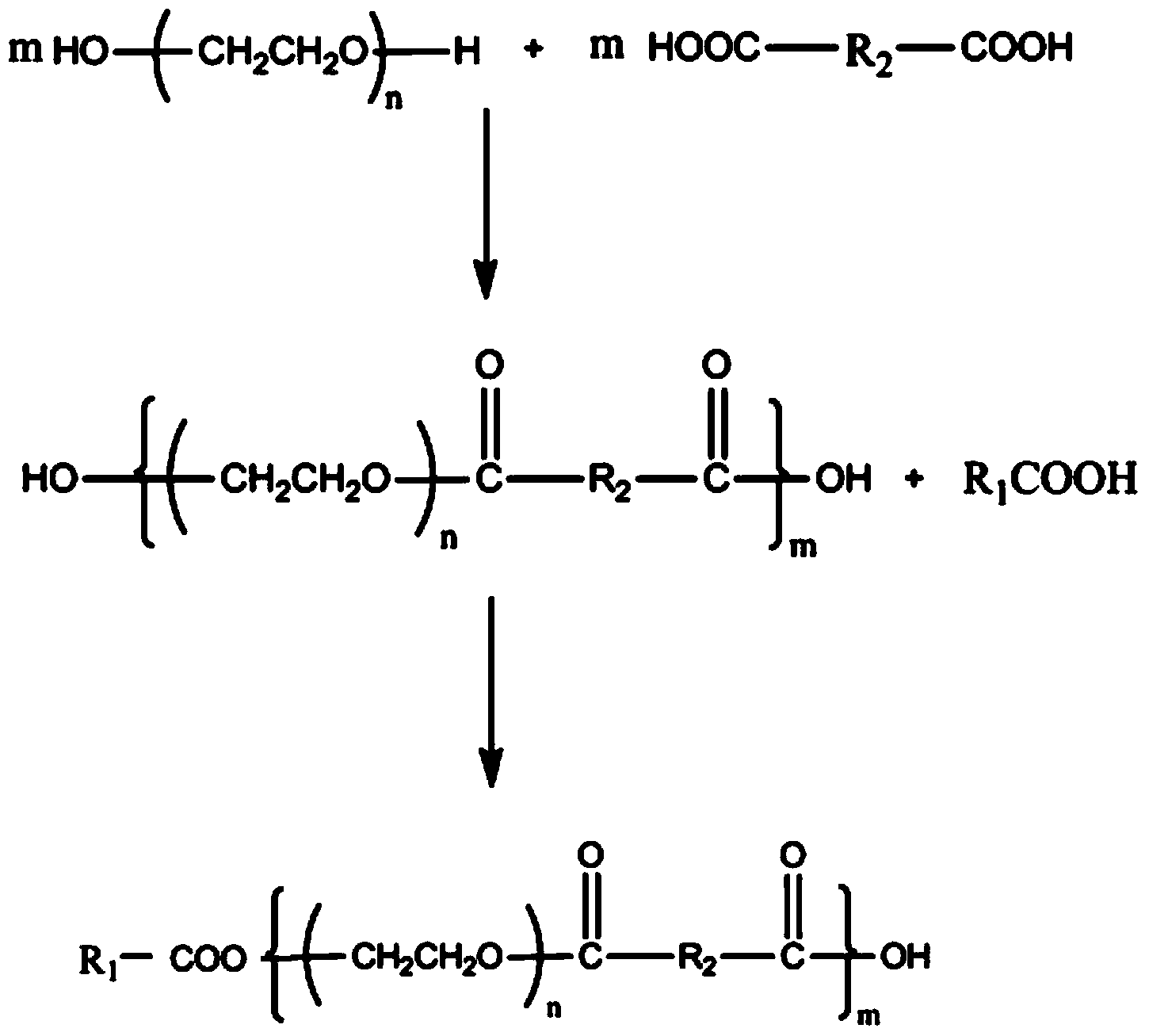

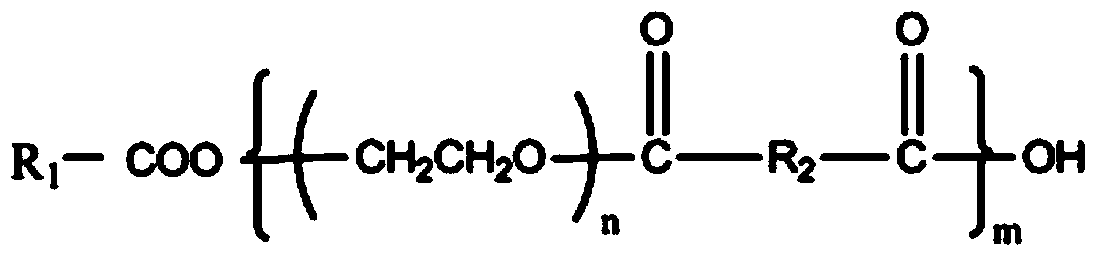

Method used

Image

Examples

Embodiment 1

[0043] Step 1. Put 106.12kg (1000mol) of diethylene glycol and 116.07kg (1000mol) of maleic acid into the reactor respectively, add 3kg of cation exchange resin, fill in nitrogen to convert the air in the reactor, and stir at the same time to raise the temperature to 220°C , reacted for 48 hours.

[0044] During the above reaction process, water was drained once every 16 hours under reduced pressure, and water was drained 3 times in total.

[0045] Step 2: Add 7 kg of oleic acid into the reaction kettle, and simultaneously stir, decompress, drain, and lower the temperature to obtain a self-emulsifying polyester.

[0046] Step 3: When the temperature drops below 100°C, the catalyst is removed. Take 100kg of self-emulsifying polyester, 10kg of triethanolamine, 1kg of ammonium molybdate, 1kg of potassium tetraborate, 1kg of dipotassium hydrogen phosphate, and 0.1kg of potassium sorbate, add them to 500kg of water, stir until completely transparent, and prepare a trace lubricant...

Embodiment 2

[0048] Step 1. Put 150.2kg (1000mol) of triethylene glycol and 146.14kg (1000mol) of adipic acid into the reactor respectively, add 5kg of cation exchange resin, fill in nitrogen to convert the air in the reactor, and stir at the same time to raise the temperature to 200°C , reacted for 72 hours.

[0049] During the above reaction process, water was drained once every 18 hours under reduced pressure, and water was drained 4 times in total.

[0050] Step 2: Add 14.5kg of lauric acid to the reactor to remove the catalyst. Stirring, decompression, drainage, and cooling at the same time, a self-emulsifying polyester is prepared.

[0051] Step 3: When the temperature drops below 100°C, take 100kg of self-emulsifying polyester, add it to 100kg of water, stir until it is completely transparent, and prepare a micro lubricant.

Embodiment 3

[0053] Step 1. Put 222.28kg (1000mol) of tetraethylene glycol and 174.19kg (1000mol) of suberic acid into the reactor respectively, add 6kg of cation exchange resin, fill in nitrogen to convert the air in the reactor, and stir at the same time to raise the temperature to 210°C , reacted for 60 hours.

[0054] During the above reaction process, water was drained once every 15 hours under reduced pressure, and water was drained 4 times in total.

[0055] Step 2: Add 16kg of stearic acid into the reaction kettle, and simultaneously stir, decompress, drain, and lower the temperature to obtain a self-emulsifying polyester.

[0056] Step 3: When the temperature drops below 100°C, the catalyst is removed. Take 100kg of self-emulsifying polyester and 2kg of potassium hydroxide, add it into 200kg of water, stir until completely transparent, and prepare a micro lubricant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com