Nano suspension containing hydroxycamptothecin and preparation method of nano suspension

A nanosuspension, hydroxycamptothecin technology, applied in the directions of liquid delivery, antitumor drugs, emulsion delivery, etc., can solve the problem of high manufacturing cost of nanoparticles and liposomes, unfavorable industrial production, and unsuitable for intravenous injection, etc. problems, to achieve high drug loading, improve bioavailability, and facilitate the clinical application of large doses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

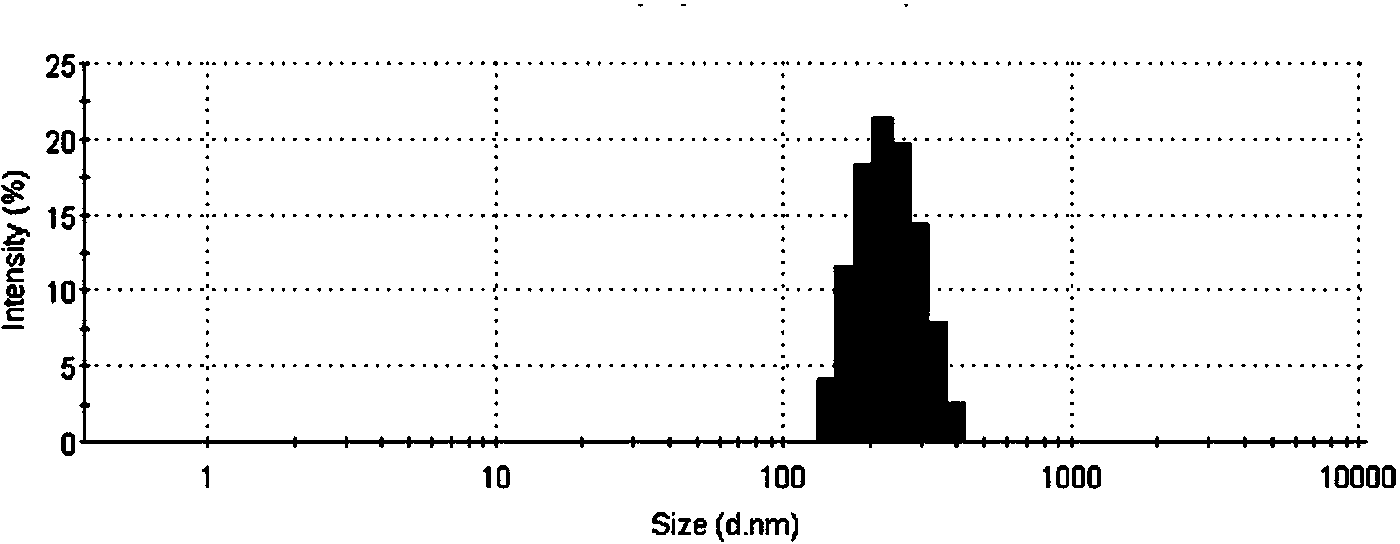

Embodiment 1

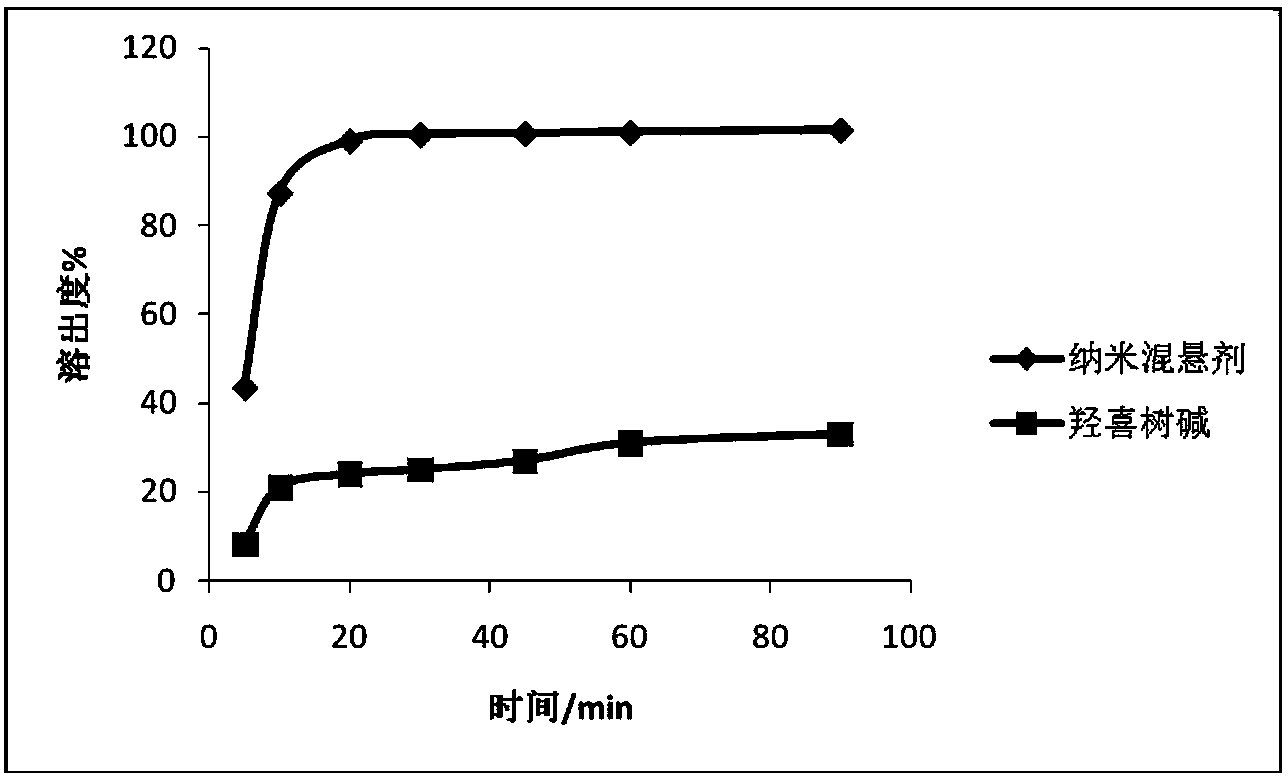

[0037] Take 50 mg of hydroxycamptothecin and put it in a beaker, add 4 ml of dichloromethane to dissolve it, and use it as an oil phase; then take 50 mg of poloxamer, 25 mg of hypromellose and 2 g of mannitol in another beaker, and add it to the beaker. 50ml of distilled water was added into it, and magnetic stirring was performed to make it fully dissolved to serve as the water phase. At room temperature, the oil phase was slowly injected into the water phase, and at the same time, the high-shear emulsifier was used for stirring at 10,000 rpm for 10 minutes. The initial suspension was rotary evaporated for 1 hour to remove the organic solvent, added to a high-pressure homogenizer, and homogenized at 1000 bar for 5 minutes. , the nanosuspension with opalescence was obtained, the particle size was 196nm measured by Malvern 2000 nanometer particle size analyzer, the zeta potential was -28.5mv, and the polydispersity coefficient was 0.11.

[0038] The prepared nanosuspension was ...

Embodiment 2

[0040] Take 50 mg of hydroxycamptothecin and place it in a beaker, add 4 ml of ethyl acetate to dissolve it as an oil phase; then take 50 mg of poloxamer and 25 mg of hypromellose in another beaker, add 50 ml of distilled water to it , magnetic stirring to make it fully dissolved, as the water phase. At room temperature, the oil phase was slowly injected into the water phase, and at the same time, the high-shear emulsifier was used for stirring at 10,000 rpm for 10 minutes, the initial suspension was rotary evaporated for 1 hour to remove the organic solvent, added to the high-pressure homogenizer, and the homogenization cycle was performed at 1000 bar. 20 times, a nanosuspension was obtained, and the particle size was 298 nm as measured by a Malvern 2000 nanometer particle size analyzer, the zeta potential was -25.6 mv, and the polydispersity coefficient was 0.25.

Embodiment 3

[0042] Take 100 mg of hydroxycamptothecin and place it in a beaker, add 4 ml of dichloromethane to dissolve it, and use it as an oil phase; then take 100 mg of poloxamer and 100 mg of hypromellose in another beaker, and add 50 ml of distilled water to it , magnetic stirring to make it fully dissolved, as the water phase. At room temperature, the oil phase was slowly injected into the water phase, and at the same time, the high-shear emulsifier was used for stirring at 10,000 rpm for 10 min. The initial suspension was rotary evaporated for 1 h to remove the organic solvent, and added to a high-pressure homogenizer. The homogenization condition was 500 bar. After 10 cycles, 5 cycles at 500bar and 5 cycles at 1000bar, the particle size of the prepared nanosuspension was 254nm, the zeta potential was -26.6mv, and the polydispersity coefficient was 0.15 as measured by a Malvern 2000 nanometer particle size analyzer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com