A kind of TPU hot-melt adhesive film with low melting point and high adhesive strength and preparation method thereof

A hot-melt adhesive film and raw material technology, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, adhesives, etc., can solve the problems of poor bonding strength and high melting point, and achieve long-lasting bonding and good adhesion. Simple process, high moisture permeability and high hydrostatic pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

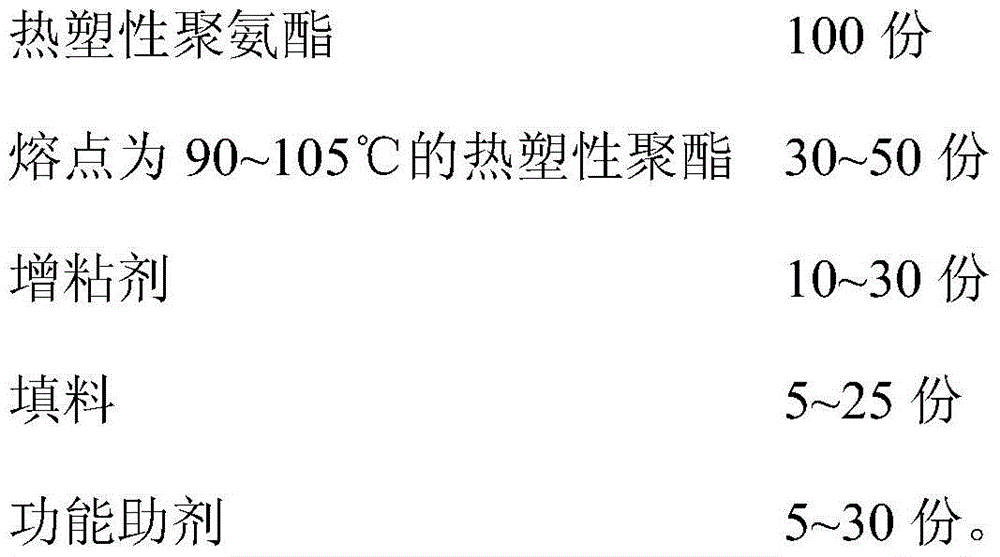

[0034] A TPU hot-melt adhesive film with low melting point and high adhesive strength, which is mainly prepared from the following raw materials in parts by weight:

[0035]

[0036] The tackifier is petroleum resin.

[0037] The filler is kaolin.

[0038] The thickness of the adhesive film is 0.03-2mm, and the thickness of the adhesive film is uniform, which can be changed according to the bonding needs of the thickness of the composite board.

[0039] The preparation method of TPU hot-melt adhesive film with low melting point and high adhesive strength as described above, said method comprises the steps:

[0040] (1) Drying each raw material of the formulation amount at 80-100°C;

[0041] (2) Extrude the dried raw material, cool it, take it up, pack it, and obtain the TPU hot-melt adhesive film.

[0042] Among them, extruder is used for extrusion, and the barrel temperature of the extruder is: 120°C, 127°C, 155°C, 155°C, 147°C and 140°C, and the die head temperature is...

Embodiment 2

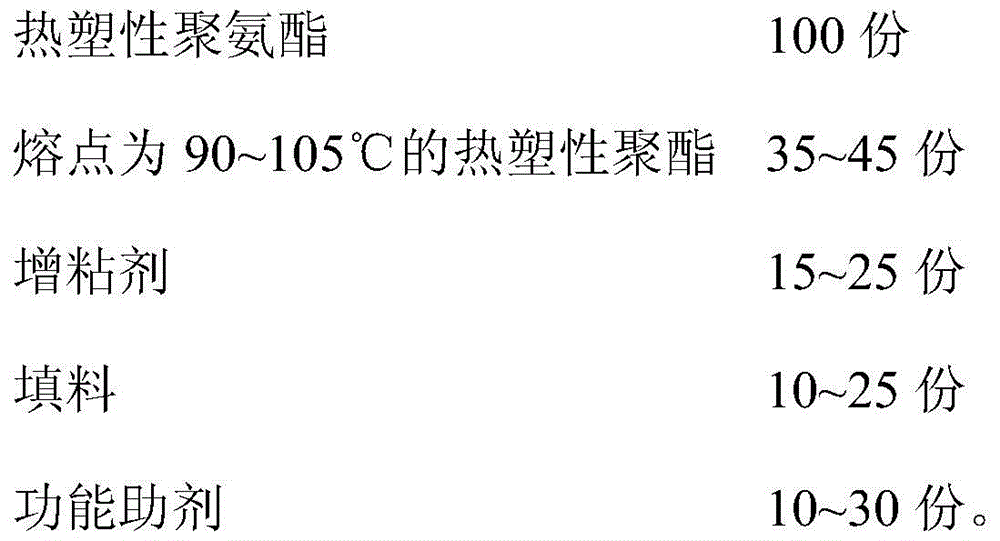

[0044] A TPU hot-melt adhesive film with low melting point and high adhesive strength, which is mainly prepared from the following raw materials in parts by weight:

[0045]

[0046] The tackifier is petroleum resin and rosin resin.

[0047] The filler is polytetrafluoroethylene powder.

[0048] The thickness of the adhesive film is 0.03-2mm, and the thickness of the adhesive film is uniform, which can be changed according to the bonding needs of the thickness of the composite board.

[0049] The preparation method of TPU hot-melt adhesive film with low melting point and high adhesive strength as described above, said method comprises the steps:

[0050] (1) Drying each raw material of the formulation amount at 80-100°C;

[0051] (2) Extrude the dried raw material, cool it, take it up, pack it, and obtain the TPU hot-melt adhesive film.

[0052] Among them, extruder is used for extrusion, and the barrel temperature of the extruder is: 120°C, 127°C, 155°C, 155°C, 147°C an...

Embodiment 3

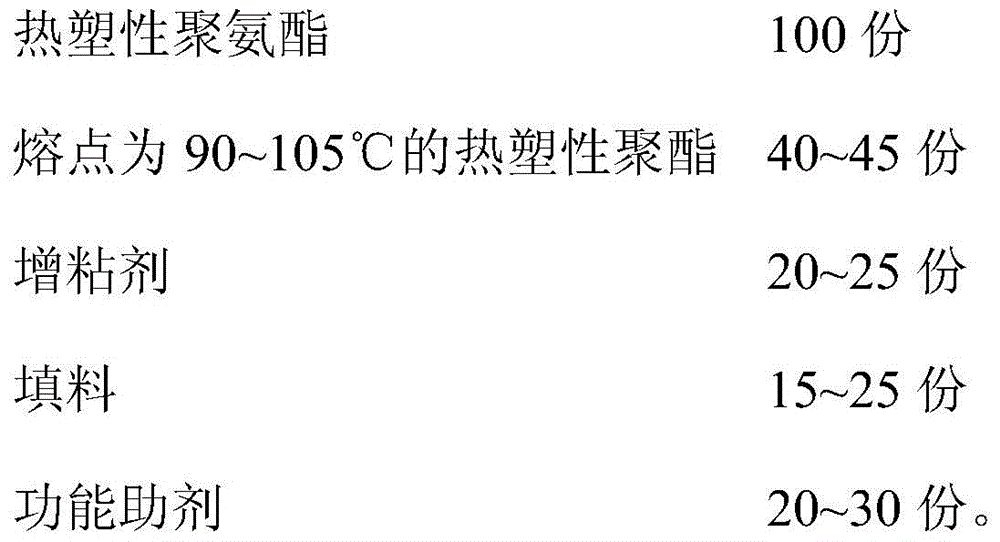

[0054] A TPU hot-melt adhesive film with low melting point and high adhesive strength, which is mainly prepared from the following raw materials in parts by weight:

[0055]

[0056]

[0057] The tackifier is acrylic modified rosin, terpene resin, phenolic resin, terpene-phenolic resin and terpene phenolic resin.

[0058]The filler is an organic filler and an inorganic filler, the inorganic filler is selected from calcium carbonate and kaolin, and the organic filler is selected from polytetrafluoroethylene powder, polyphenylene sulfide and polyethersulfone powder.

[0059] The thickness of the adhesive film is 0.03-2mm, and the thickness of the adhesive film is uniform, which can be changed according to the bonding needs of the thickness of the composite board.

[0060] The preparation method of TPU hot-melt adhesive film with low melting point and high adhesive strength as described above, said method comprises the steps:

[0061] (1) Drying each raw material of the fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com