Enhanced aluminum matrix composite brake block

A technology of aluminum-based composite materials and brake pads, which is applied in the field of auto parts, can solve the problems of general heat dissipation, high-speed fading, and low strength, and achieve the effects of reducing high-temperature thermal fading, preventing high-speed fading, and simple production technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

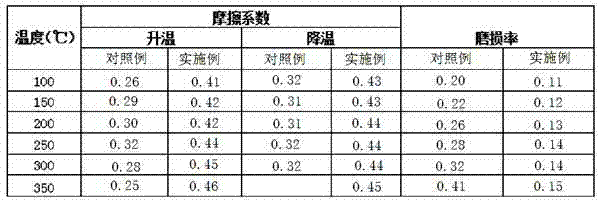

Embodiment 1

[0008] A reinforced aluminum-based composite brake pad, which is made of raw materials through mixing, hot pressing (200-250Mpa, 8-10 minutes) and curing process (350-380 degrees Celsius solid solution for 3-4 hours, water cooling, 220-240 Celsius solution-aging treatment for 7-8 hours), the raw materials include 20 parts by weight of cast aluminum alloy ZAlSi8MgBe powder, 10 parts by weight of silicon carbide, 6 parts by weight of potassium titanate fiber, and 6 parts by weight of aramid fiber , 1 part by weight of glass fiber, 6 parts by weight of zirconia, 3 parts by weight of tetraacicular zinc oxide whiskers, 2 parts by weight of molybdenum disulfide, 2 parts by weight of barium sulfate, 2 parts by weight of tungsten carbide; The diameter is 10 μm, the length of potassium titanate fiber is 18 μm, the length of aramid fiber is 2 mm, the diameter of single filament is 10 μm, the glass fiber is 120 mesh glass fiber powder, the length of four needle-shaped zinc oxide whiskers ...

Embodiment 2

[0010] An enhanced aluminum-based composite material brake pad is made of raw materials through mixing, hot pressing and curing processes. The raw materials include 30 parts by weight of cast aluminum alloy ZAlSi8MgBe powder, 8 parts by weight of silicon carbide, and 8 parts by weight of Potassium titanate fiber, 5 parts by weight of aramid fiber, 2 parts by weight of glass fiber, 5 parts by weight of zirconia, 4 parts by weight of tetrapod zinc oxide whiskers, 1 part by weight of molybdenum disulfide, 2 parts by weight of sulfuric acid Barium, 1 part by weight of tungsten carbide; the particle size of silicon carbide is 12 μm, the length of potassium titanate fiber is 16 μm, the length of aramid fiber is 2.5 mm, the diameter of single filament is 8 μm, and the glass fiber is 140 mesh glass fiber powder, four-needle oxidation The length of the zinc whiskers is 10 μm, the root diameter is 1.5 μm, the particle size of zirconia is 3 μm, the particle size of molybdenum disulfide is...

Embodiment 3

[0012] An enhanced aluminum-based composite material brake pad is made of raw materials through mixing, hot pressing and curing processes. The raw materials include 25 parts by weight of cast aluminum alloy ZAlSi8MgBe powder, 9 parts by weight of silicon carbide, and 7 parts by weight of Potassium titanate fiber, 5 parts by weight of aramid fiber, 2 parts by weight of glass fiber, 6 parts by weight of zirconia, 4 parts by weight of tetrapod zinc oxide whiskers, 1 part by weight of molybdenum disulfide, 2 parts by weight of sulfuric acid Barium, 2 parts by weight tungsten carbide. The particle size of silicon carbide is 12 μm, the length of potassium titanate fiber is 16 μm, the length of aramid fiber is 2.5 mm, the diameter of monofilament is 8 μm, the glass fiber is 140 mesh glass fiber powder, the length of four needle-shaped zinc oxide whiskers is 10 μm, The root diameter is 1.5 μm, the particle size of zirconia is 3 μm, the particle size of molybdenum disulfide is 30 nm, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com