Method for treating phenolic waste water

A waste water and phenol technology, which is applied in water/sewage treatment, chemical instruments and methods, special compound water treatment, etc., can solve the problems of high treatment efficiency of phenol waste water, heating and pressurizing, and low safety, and achieve the effect of phenol degradation Good, mild reaction conditions, increased safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

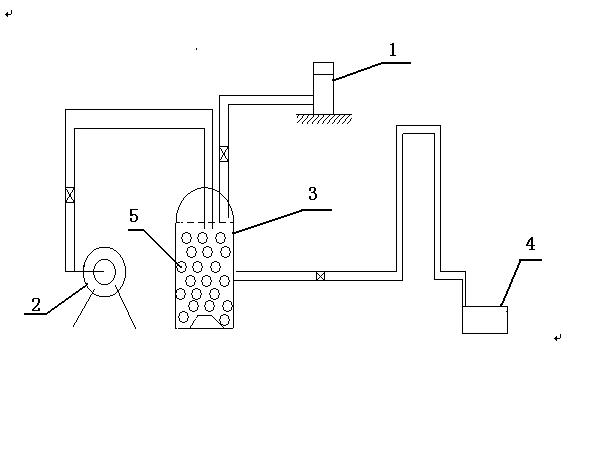

[0030] The present invention will be further described below in conjunction with specific embodiments with reference to the accompanying drawings, so as to better understand the present invention.

[0031]

[0032] Prepare activated carbon-supported nanoscale titanium dioxide catalyst according to the following steps:

[0033] a. Disperse the nano-scale titanium dioxide powder in the mixed solution containing granular activated carbon, soak for 10 hours, filter, dry and roast the solid;

[0034] b. soaking the calcined solid in the filtrate obtained by filtering, soaking for 5 hours, filtering, drying and roasting the solid;

[0035] c. Repeat step b at least 5 times.

[0036] The prepared activated carbon-supported nano-scale titania catalyst 5 is loaded into the reaction tower 3 .

[0037] Preparation of ClO in Chlorine Dioxide Generator Using Filler Contact Process Using Sodium Chlorate and Hydrochloric Acid as Raw Materials 2 , NaClO 3 ClO 2 +NaCl+H 2 O. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com