Preparation method for fluorescent western-blotting magnetic composite microballoon

A magnetic composite microsphere and fluorescent protein technology, which is applied in the fields of material science and engineering and biological separation engineering, can solve the problems of cumbersome and complicated operation process, and achieve the effects of fast mass transfer rate, high adsorption efficiency and uniform particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] a.Fe 3 o 4 Magnetic material preparation: weigh 3.00g of FeCl 3 ·6H 2 O was dissolved in 90mL of ethylene glycol, and 7.2g of sodium acetate was added, sonicated and mechanically stirred to dissolve. Then add 3.9g of polyethylene glycol and stir at 400r / min at 60°C until dissolved. After dissolution, all the yellow liquid was transferred to a closed hydrothermal reaction kettle with a polytetrafluoroethylene liner, and reacted in a dry oven at 200°C for 10 hours. After cooling to room temperature, the black substance was collected magnetically, washed with ultrapure water and absolute ethanol for 6 times, and the obtained product was dried for 24 hours, and the dried Fe 3 o 4 magnetic material.

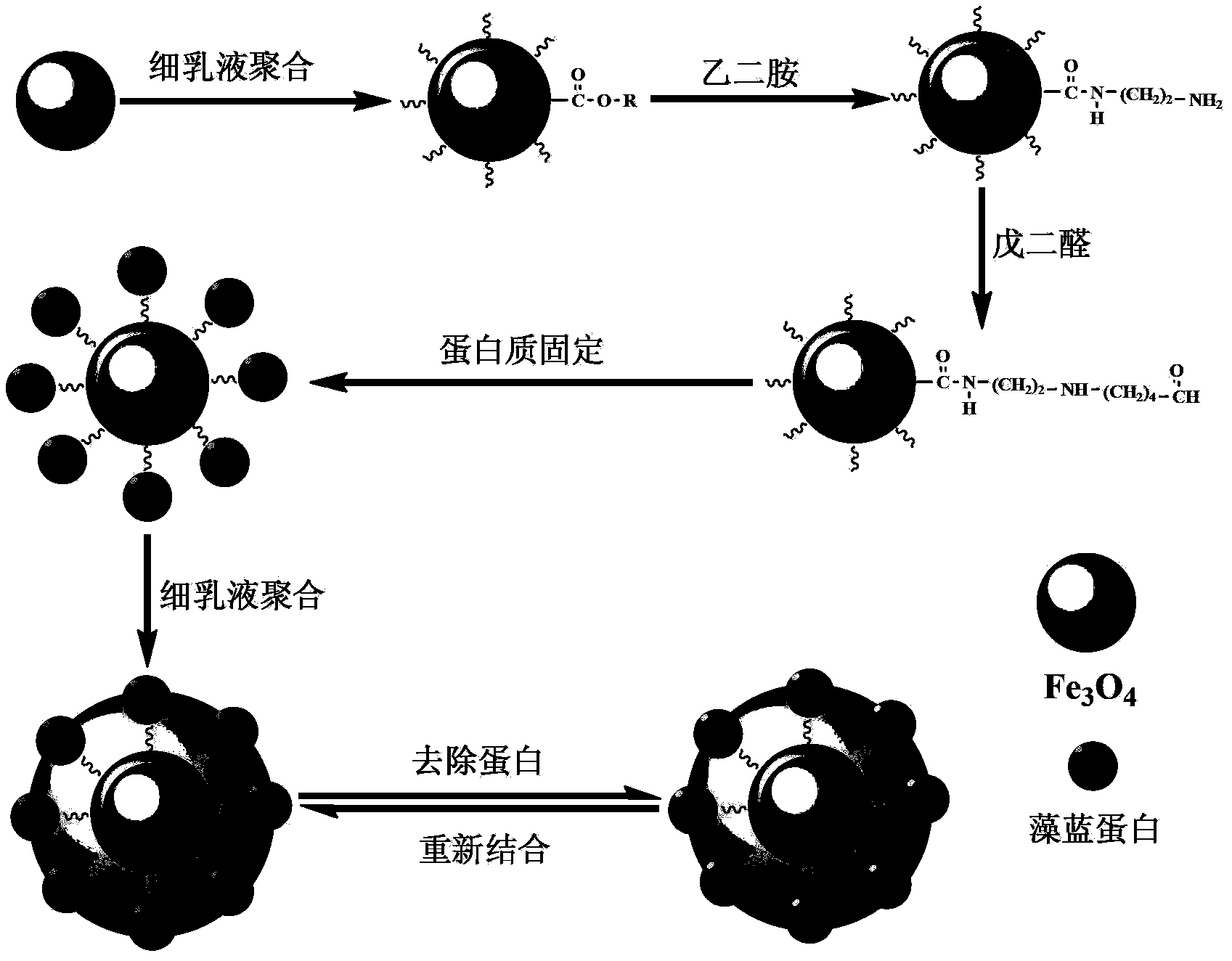

[0043] b. Synthesis of superparamagnetic carrier particles by one-step miniemulsion polymerization: 1.0 g of the above-mentioned Fe 3 o 4 The magnetic material was mixed with 1 mL of oleic acid to obtain a black viscous gel. Methyl methacrylate (1.28 mL) and ethylene g...

Embodiment 2

[0052] Weigh 20mg of phycocyanin, dilute it in a 1L volumetric flask with redistilled water to obtain a 20mg / L phycocyanin solution, take 10mL of phycocyanin solution and add it to a 20mL screw-top vial, add 100mg of fluorescent Western blotting magnetic composite microspheres, oscillating for 10 minutes, and using a magnet to adsorb on one side of the vial for 2 minutes, the composite microspheres can be adsorbed to one side to obtain a clear solution (see Figure 2A ). It shows that the composite microsphere has a strong adsorption capacity for phycocyanin, and the separation process is fast and simple, see Figure 2B The magnetic strength of the microspheres is shown to be high.

Embodiment 3

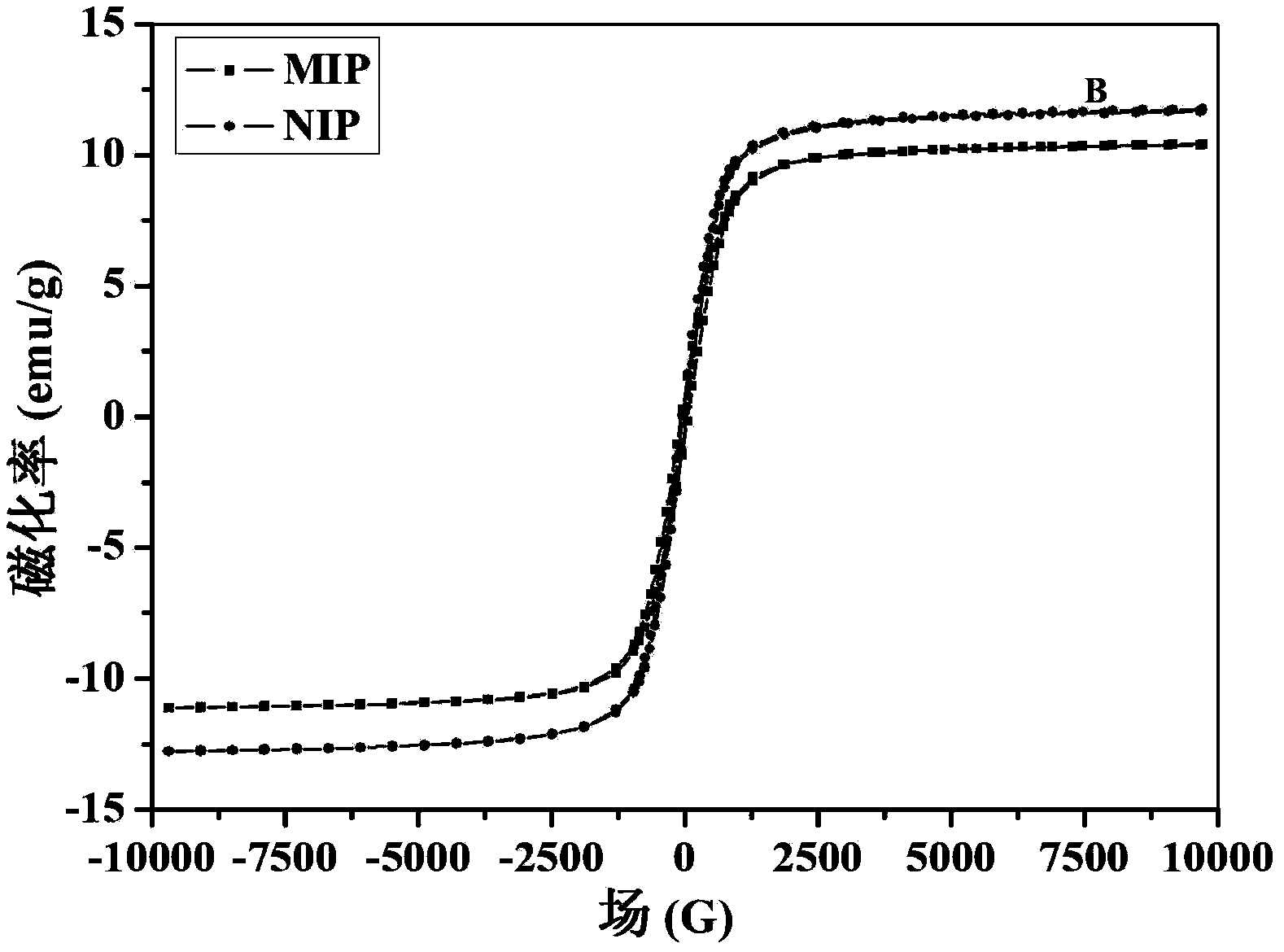

[0054] Take 200 μL of 7 parts of 100 mg / L phycocyanin solution, place them in 10 mL plastic centrifuge tubes, and then add phosphate buffer solution (Na 2 HPO 4 and NaH 2 PO 4 0.2mol / L, volume ratio 1:1) 9.8mL, dilute to obtain 2mg / L phycocyanin solutions with pH values of 5.6, 6.0, 6.4, 6.8, 7.2, 7.6 and 8.0, respectively, with a fluorescence spectrophotometer Determination of its corresponding fluorescence intensity, the maximum fluorescence intensity can be obtained when the pH value is 6.4 (see Figure 3A ), and as the concentration of phycocyanin increases, the fluorescence intensity increases gradually (see Figure 3B ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com