High-adhesion-property low-linear-expansion-coefficient polyimide film material and preparation method thereof

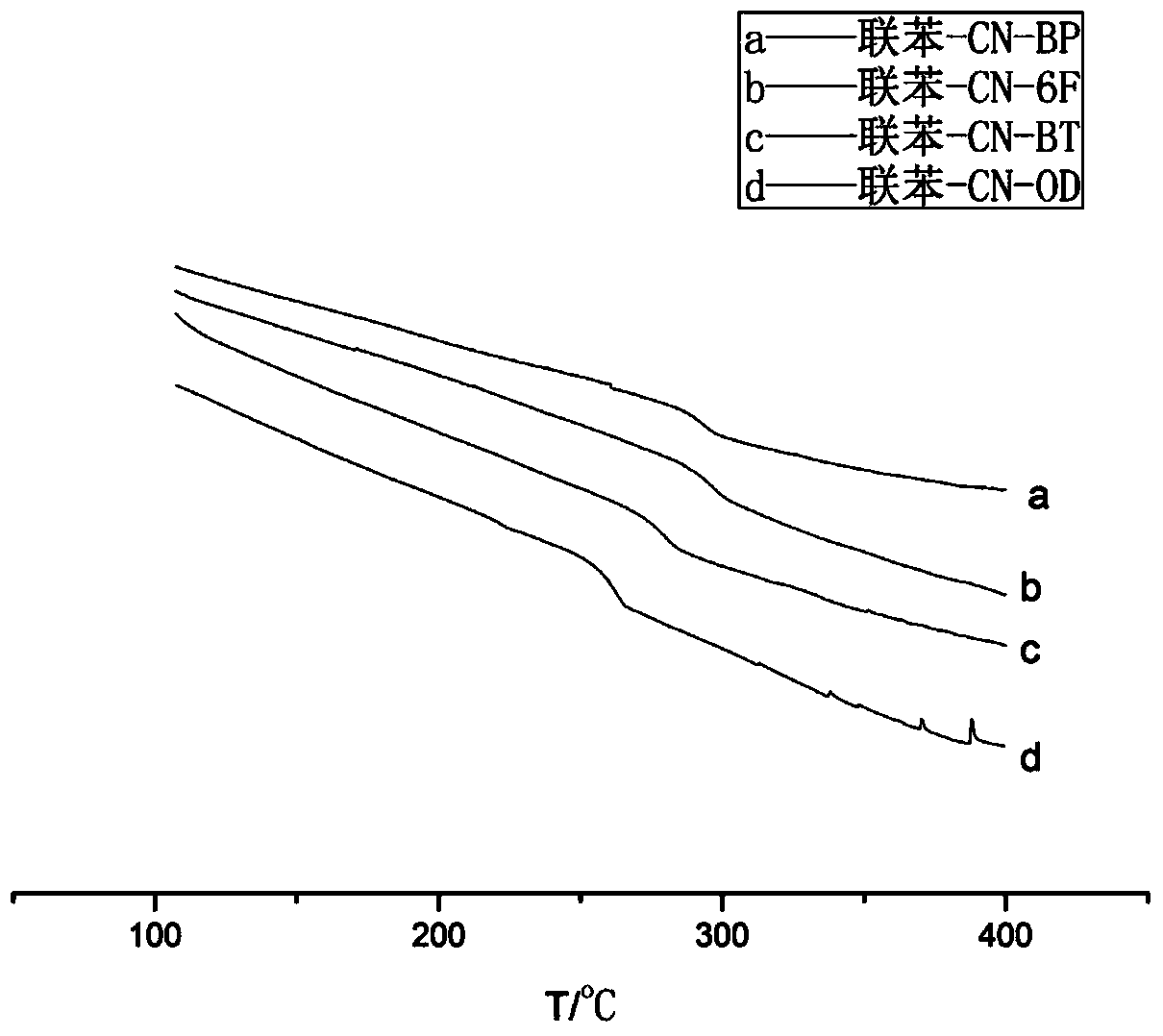

A technology of polyimide film and linear expansion coefficient, which is applied in the field of polymer material synthesis, can solve the problems of poor adhesion, oligoimide, and can only be reached, and achieves improved adhesion performance and low thermal expansion coefficient. , the effect of good dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

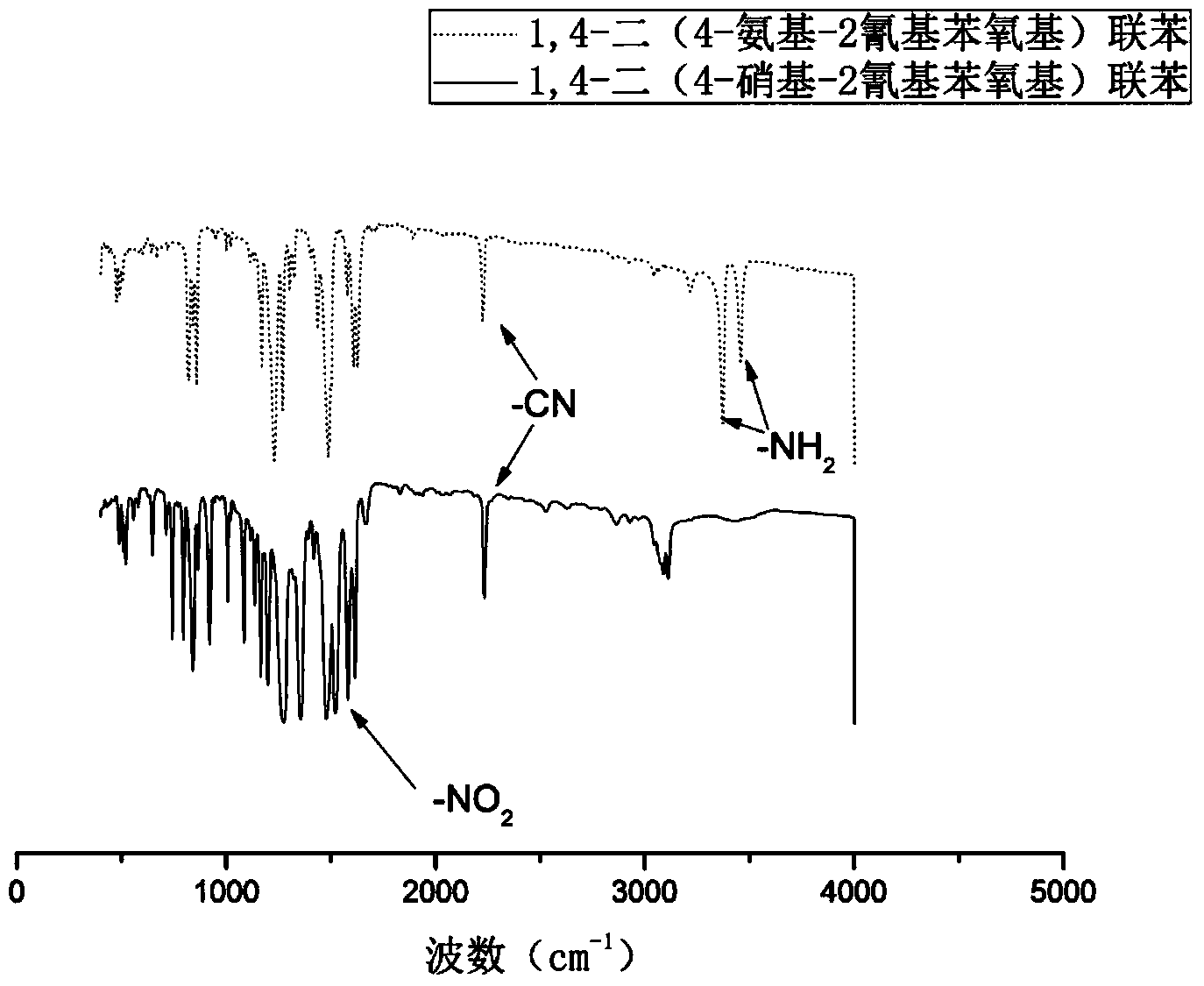

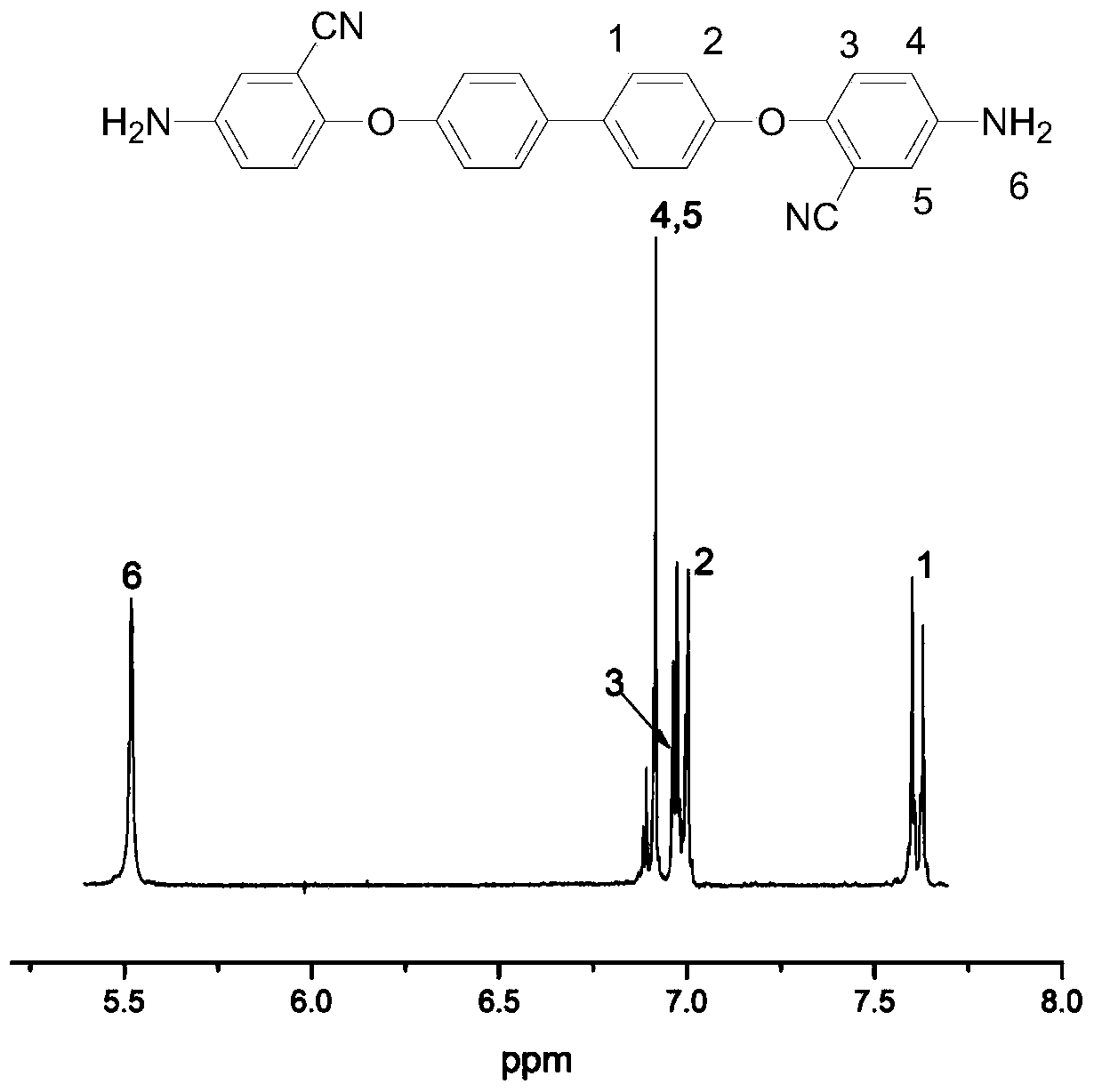

[0053] 1) Preparation of nitro compounds

[0054] Add biphenol 18.6207g (0.1mol), 2-chloro-5-nitrobenzonitrile 38.3384g ( 0.21mol), anhydrous K2CO 3 16.5847g (0.12mol), 141ml of DMF (the percentage of the total weight of raw material monomers to the weight of the whole material is 30%, that is, the solid content) and 20ml of toluene, the initial reaction temperature is 135 ~ 140 ° C, with water for 2 ~ 3 hours, gradually increase the temperature When the reaction temperature is 150-155°C, continue the reaction for 4-6 hours, filter while it is hot and discharge it into ice ethanol to obtain a large amount of bright yellow precipitate. After filtering, wash the crude product in deionized water for 3-4 times until the filtrate is almost Reflux in hot ethanol for 2 to 3 hours to remove organic impurities, recrystallize in DMSO solvent, filter, cool and dry in a vacuum oven for 24 hours to obtain bright yellow nitro compound 1,4-bis(4-nitro- 2 cyanophenoxy) biphenyl 46g, yield 8...

Embodiment 2

[0061] According to the operation prepared by the nitro compound in Example 1, the anhydrous K 2 CO 3 The input amount is increased to 20.7g (0.15mol), all the other conditions are constant, obtain the characterization result of product 1,4-bis(4-nitro-2 cyanophenoxy)biphenyl and the nitro compound of embodiment 1 The characterization results are consistent.

Embodiment 3

[0063]According to the operation of the preparation of the nitro compound in Example 1, only the addition of DMF is changed to 112ml (the solid content of the system is increased from 30% to 35%) to obtain the product 1,4-two (4-nitro-2 cyano) The characterization result of phenoxy)biphenyl is consistent with the characterization result of the nitro compound in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tg value | aaaaa | aaaaa |

| Linear expansion coefficient | aaaaa | aaaaa |

| Tg value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com