Orange peel feed production method

A production method and technology of citrus peel, applied in the direction of animal feed, animal feed, application, etc., can solve the problems of low capacity, limited application of microbial fermentation method, inability to effectively degrade pectin, etc., achieve good palatability, solve waste and environmental problems Effects of low pollution and plague rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

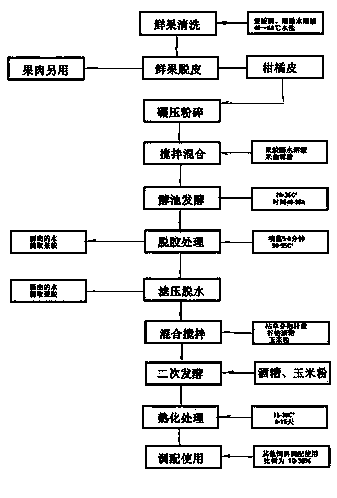

Method used

Image

Examples

Embodiment 1

[0019] Suckling pig feed

[0020] 1. Cleaning of fresh fruit: use 0.4% pectinase aqueous solution and 0.8% acetic acid aqueous solution in the cleaning tank, and soak for 60 minutes at a liquid temperature of 60°C;

[0021] 2. Fresh fruit peeling: filter and peel on the conveying roller on the peeling machine;

[0022] 3. Rolling and crushing: Rolling on a roller compactor to squeeze out the water to obtain citrus peel slag with a moisture content of 25%, and crush the citrus peel slag on the grinder to a granular shape of 3 mm in thickness;

[0023] 4. Stir and mix: add 0.4% pectinase aqueous solution according to 0.8:1000 parts by weight in citrus peel, add Aspergillus oryzae powder according to 0.6:1000 parts by weight, stir and mix evenly;

[0024] 5. Fermentation tank fermentation: Add pectinase and Aspergillus oryzae powder, stir and mix evenly, and put the citrus peel residue into the fermentation tank for fermentation, the temperature is controlled at 30°C, and the ti...

Embodiment 2

[0032] Feed for piglets, growing pigs, and fattening pigs

[0033] 1. Cleaning of fresh fruit: use 0.5% pectinase aqueous solution and 1% acetic acid aqueous solution in the cleaning tank, and soak for 60 minutes at a liquid temperature of 60°C;

[0034] 2. Fresh fruit peeling: filter and peel on the conveying roller on the peeling machine, keep the citrus peel for use, and use the pulp separately;

[0035] 3. Rolling and crushing: Rolling on a roller compactor to squeeze out the water to obtain citrus peel slag with a moisture content of 25%, and crush the citrus peel slag on the grinder to a granular shape of 3 mm in thickness;

[0036] 4. Stir and mix: add 0.5% pectinase aqueous solution according to 1:1000 parts by weight in citrus peel, add Aspergillus oryzae powder according to 0.8:1000 parts by weight, stir and mix evenly;

[0037] 5. Fermentation tank fermentation: Add pectinase and Aspergillus oryzae powder, stir and mix evenly, put the citrus peel residue into...

Embodiment 3

[0045] Cattle and sheep feed

[0046] 1. Cleaning of fresh fruit: use 0.4% pectinase aqueous solution and 0.8% acetic acid aqueous solution in the cleaning tank, and soak for 30-60 minutes at a liquid temperature of 60°C;

[0047] 2. Fresh fruit peeling: filter and peel on the conveying roller on the peeling machine, keep the citrus peel for use, and use the pulp separately;

[0048] 3. Rolling and crushing: Rolling on the roller compactor to squeeze out the water to obtain citrus peel slag with a moisture content of 20-30%, and crush the citrus peel slag on the grinder to a granular shape of 2-4 mm in thickness;

[0049] 4. Stirring and mixing: add 0.4% pectinase aqueous solution according to 0.5-1:1000 parts by weight to the citrus peel, add Aspergillus oryzae powder according to 0.6:1000 parts by weight, stir and mix evenly;

[0050]5. Fermentation tank fermentation: Add pectinase and Aspergillus oryzae powder, stir and mix evenly, and put the citrus peel residue into the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com