Preparation method of electrocatalyst carrier for fuel cell

An electrocatalyst and fuel cell technology, applied in the field of materials, can solve problems such as easy agglomeration of carbon black, easy coating of Pt, and many surface atomic defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

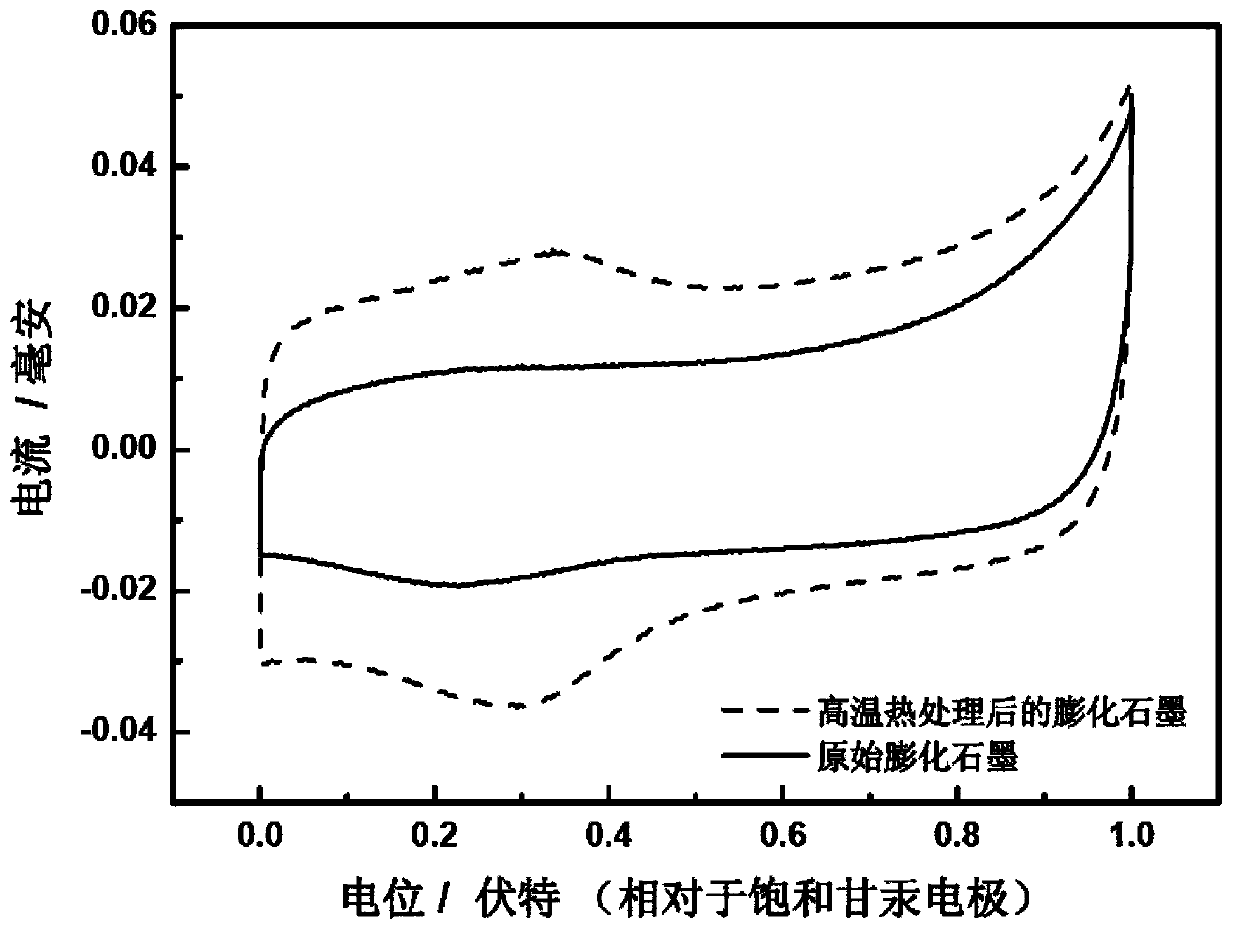

[0043] 1) High temperature calcination treatment of vermicular expanded graphite material

[0044] Take the BET specific surface area as 300m 2 / g, average pore diameter is 600mg of expanded graphite material of 20nm, is placed in tube furnace, in N 2 After heat treatment at 600°C for 3h under atmosphere, cool down to room temperature.

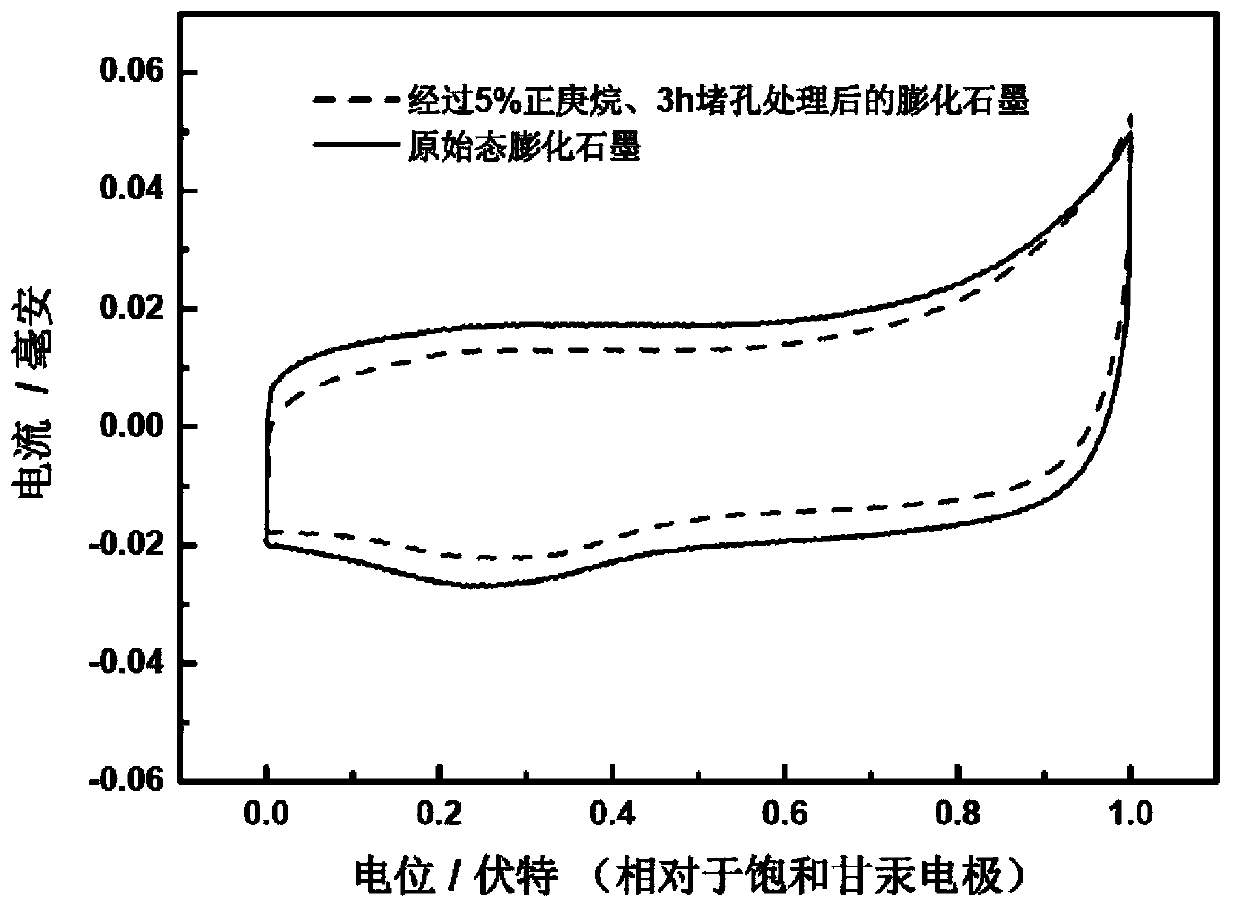

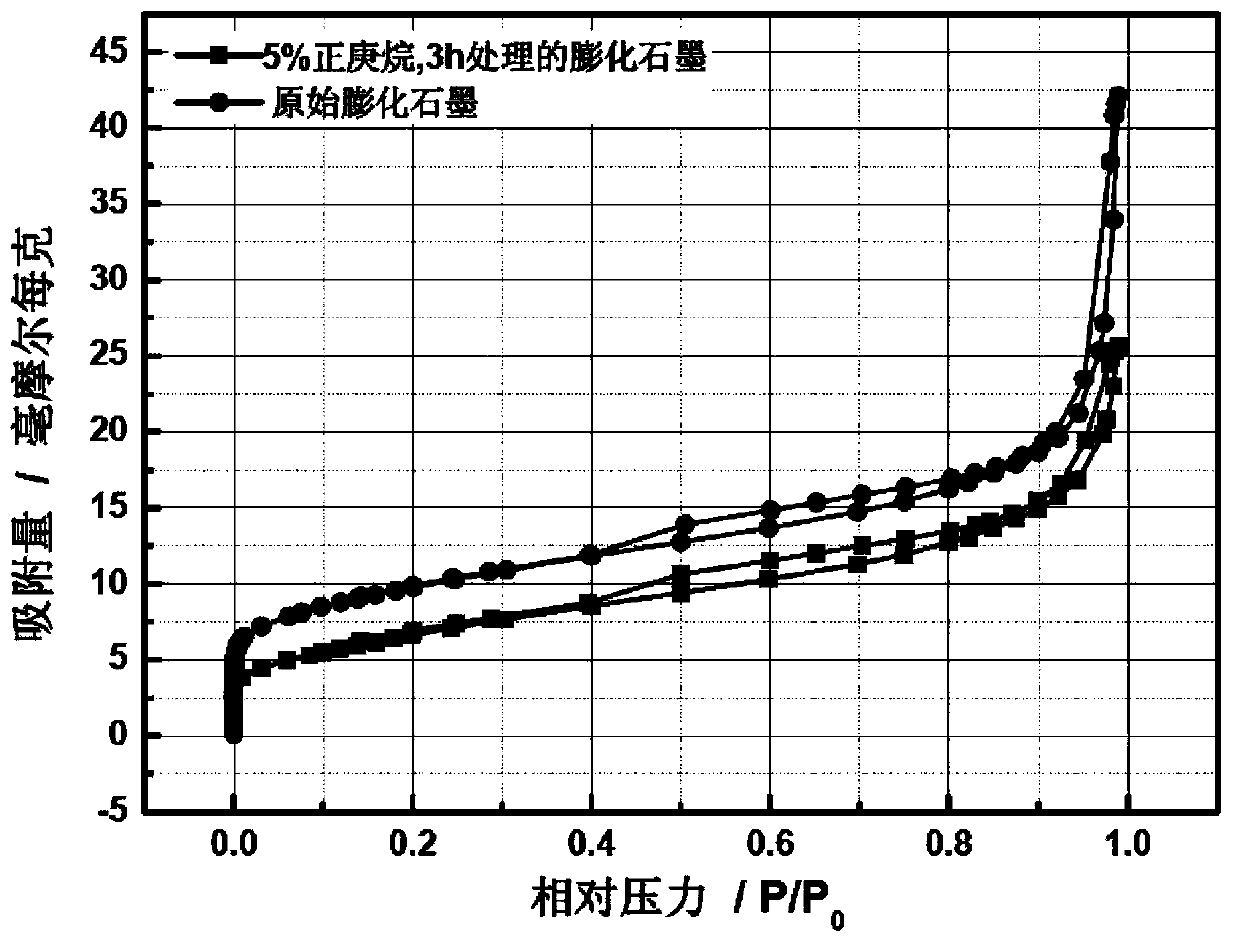

[0045] 2) Clogging treatment of worm-like expanded graphite material

[0046] Take 1.5ml of n-heptane and dissolve it in 78.5ml of absolute ethanol; weigh 200mg of expanded graphite material that has been heat-treated at high temperature, disperse it in the above solution, ultrasonicate and stir evenly; heat up from room temperature at 5°C / min to 80±2 ℃, after reflux dipping for 1.5h, let stand to cool down to room temperature.

[0047] 3) Drying by rotary evaporation under reduced pressure

[0048] Rotary steam the slurry in 2) at 38°C and -0.05MPa under reduced pressure for 1 hour, and the rotation speed is 50rpm.

[0049] 4) Vacuum dry...

Embodiment 2

[0057] 1) High temperature calcination treatment of vermicular expanded graphite material

[0058] Take the BET specific surface area as 100m 2 / g, 600mg of expanded graphite material with an average pore diameter of 50nm, placed in a tube furnace, heat-treated at 1000°C for 6h under an Ar atmosphere, and then cooled to room temperature.

[0059] 2) Clogging treatment of worm-like expanded graphite material

[0060] Take 2.5ml of nonane and dissolve it in 77.5ml of absolute ethanol; weigh 200mg of expanded graphite material that has been heat-treated at high temperature, and disperse it in the above solution; heat up from room temperature at 10°C / min to 80±2°C, and reflux for 3 hours , let it cool down to room temperature.

[0061] 3) Drying by rotary evaporation under reduced pressure

[0062] Rotate the slurry in 2) at 45°C and -0.1MPa under reduced pressure for 0.5h, with a rotation speed of 100rpm.

[0063] 4) Vacuum drying

[0064] Transfer the powder obtained in 3) ...

Embodiment 3

[0073] 1) High temperature calcination treatment of vermicular expanded graphite material

[0074] Take the BET specific surface area as 500m 2 / g, 600mg of expanded graphite material with an average pore diameter of 15nm, placed in a tube furnace, heat-treated at 500°C for 9h under an Ar atmosphere, and then cooled to room temperature.

[0075] 2) Clogging treatment of worm-like expanded graphite material

[0076] Take 5.0ml of decane and dissolve it in 75.0ml of ether; weigh 200mg of expanded graphite material that has been heat-treated at high temperature, and disperse it in the above solution; raise the temperature from room temperature to 35±2°C at 5°C / min, reflux for 5 hours, and then statically Allow to cool down to room temperature.

[0077] 3) Drying by rotary evaporation under reduced pressure

[0078] Rotate the slurry in 2) at 30°C and -0.1MPa for 2 hours under reduced pressure, and the rotation speed is 80rpm.

[0079] 4) Vacuum drying

[0080] Transfer the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com