A process for recovering ammonia from tungsten smelting ammonia nitrogen wastewater waste gas

A technology for ammonia nitrogen waste water and ammonia recovery, applied in the field of ammonia recovery process, can solve the problems of low available value, increased cost, uncompetitive enterprises, etc., and achieves the effects of easy control, low cost and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

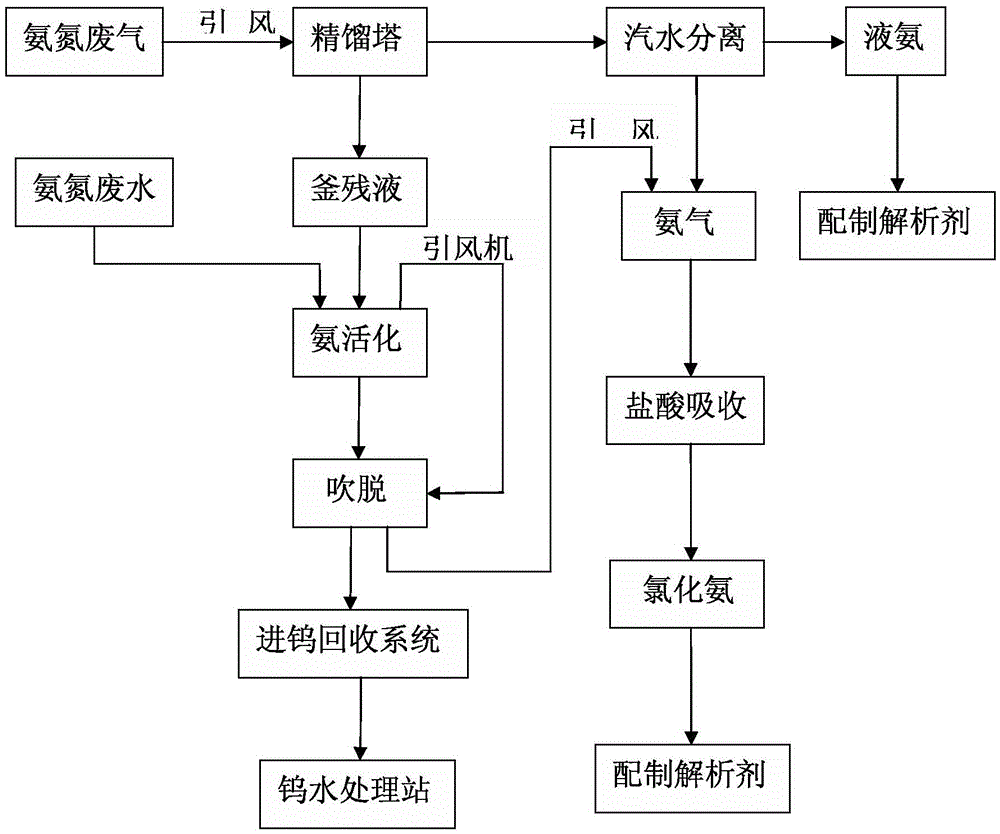

[0022] Example 1: Such as figure 1 Said, the process for recovering ammonia from the waste gas of ammonia nitrogen from tungsten smelting:

[0023] Step one, the APT crystallization steam and ammonia tail gas (ammonia content is 3000mg / m 3 ) Introduce the rectification tower through the induced draft fan, control the temperature to be maintained at 90℃, and recover the ammonia through the steam-water separator. The recovered liquid ammonia is 0.16m in 1 hour 3 .

[0024] Step two, the kettle residue after the rectification of ammonia nitrogen waste gas and ammonia nitrogen wastewater 20m 3 (Ammonia content is 30g / L) pump into a stirred tank, add sodium hydroxide with a concentration of 150g / L to activate ammonia, adjust the pH to 10, and pump to the stripping tower after ammonia activation. Ammonia waste gas is introduced into the stripping tower, adding 150g / L sodium hydroxide to adjust the pH to 10, and stripping at 45°C for 2h. After stripping, the ammonia nitrogen concentration...

Embodiment 2

[0026] Example 2: Such as figure 1 Said, the process for recovering ammonia from the waste gas of ammonia nitrogen from tungsten smelting:

[0027] Step one, the APT crystallization steam and ammonia tail gas (ammonia content is 3500mg / m 3 ) Introduce the rectification tower through the induced draft fan, control the temperature to maintain at 90℃, and recover the ammonia through the steam-water separator. The recovered liquid ammonia is 0.20m in 1 hour 3 .

[0028] Step two, the kettle residue after the rectification of ammonia nitrogen waste gas and ammonia nitrogen wastewater 20m 3 (Ammonia content is 40g / L) pump into the stirring tank, add 150g / L sodium hydroxide for ammonia activation, adjust the pH to 11, after ammonia activation, pump to the stripping tower, and at the same time the ammonia activated Ammonia waste gas is introduced into the stripping tower, adding 150g / L sodium hydroxide to adjust the pH to 11, and stripping at 90°C for 2h. After stripping, the ammonia nitro...

Embodiment 3

[0030] Example 3: Such as figure 1 Said, the process for recovering ammonia from the waste gas of ammonia nitrogen from tungsten smelting:

[0031] Step one, the APT crystallization steam and ammonia tail gas (ammonia content is 3500mg / m 3 ) Introduce the rectification tower through the induced draft fan, control the temperature to maintain at 95℃, and recover the ammonia through the steam-water separator. The recovered liquid ammonia is 0.22m in 1 hour 3 .

[0032] Step two, the kettle residue after the rectification of ammonia nitrogen waste gas and ammonia nitrogen wastewater 20m 3 (Ammonia content is 40g / L) pump into the stirring tank, add 150g / L sodium hydroxide for ammonia activation, adjust the pH to 11, after ammonia activation, pump to the stripping tower, and at the same time the ammonia activated Ammonia waste gas is introduced into the stripping tower, adding 150g / L sodium hydroxide to adjust the pH to 11.5, and stripping at 90°C for 2h. After stripping, the ammonia nit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com