Method for preparing polyether glycol with rape stalks as raw materials

A technology of polyether polyol and rape straw, which is applied in the field of polymer chemistry research, can solve the problems of complex operation, raw material modification, and many side reactions, and achieve the effect of simple process, mild conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

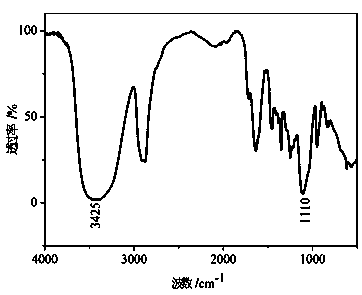

Image

Examples

Embodiment 1

[0032] A preparation method of polyether polyol using rape stalks as raw material, specifically comprising the following steps:

[0033] (1) Crush the rape straw to 30 mesh, and bake it at 120°C for 1 hour to obtain straw powder;

[0034] (2) According to the ratio of liquefaction agent: catalyst mass ratio of 100:5, add liquefaction agent and catalyst in sequence to a four-necked flask container equipped with a mechanical stirrer, condenser and thermometer, and heat up to 100°C while stirring. ℃, to obtain a mixed solution;

[0035] Described liquefaction agent is the mixture that the polyethylene glycol of glycerol and molecular weight 400 g / mol is formed in the ratio of 3:9 by mass ratio;

[0036] Described catalyst is sulfuric acid;

[0037] (3) Add the straw powder obtained in step (1) to the mixed solution obtained in step (2), continue to heat up to 120°C and react for 120 minutes, then naturally cool down to room temperature to obtain a reaction solution;

[0038] T...

Embodiment 2

[0045] A preparation method of polyether polyol using rape stalks as raw material, specifically comprising the following steps:

[0046] (1) Crush the rape straw to 30 mesh, and bake it at 120°C for 1 hour to obtain straw powder;

[0047] (2) According to the ratio of liquefaction agent: catalyst mass ratio of 100:3, add liquefaction agent and catalyst in sequence to a four-necked flask container equipped with a mechanical stirrer, condenser and thermometer, and heat up to 140°C while stirring. ℃, to obtain a mixed solution;

[0048] Described liquefaction agent is the mixture that the polyethylene glycol of glycerol and molecular weight 400 g / mol is formed in the ratio of 3:3 by mass ratio;

[0049] Described catalyst is sulfuric acid;

[0050] (3) Add the straw powder obtained in step (1) to the mixed solution obtained in step (2), continue to heat up to 160°C and react for 140 minutes, then naturally cool down to room temperature to obtain a reaction solution;

[0051] T...

Embodiment 3

[0058] A preparation method of polyether polyol using rape stalks as raw material, specifically comprising the following steps:

[0059] (1) Crush the rape straw to 30 mesh, and bake it at 120°C for 1 hour to obtain straw powder;

[0060] (2) According to the mass ratio of liquefaction agent:catalyst of 100:1, add the liquefaction agent and catalyst into the four-neck flask container equipped with mechanical stirrer, condenser and thermometer in turn, and heat up to 150°C while stirring. ℃, to obtain a mixed solution;

[0061] Described liquefier is the mixture that glycerol and the polyethylene glycol of molecular weight 400 g / mol are formed in the ratio of 3:1 by mass ratio;

[0062] Described catalyst is sulfuric acid;

[0063] (3) Add the straw powder obtained in step (1) to the mixed solution obtained in step (2), continue to heat up to 170°C for 60 minutes, and then naturally cool down to room temperature to obtain a reaction solution;

[0064] The amount of straw pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

| Hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com