Agricultural liquid mulching film and production method thereof

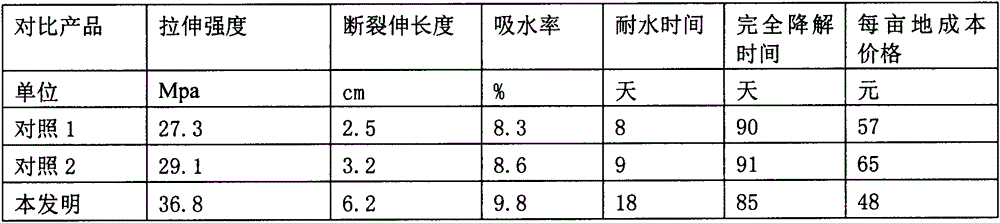

An agricultural mulch, liquid technology, applied in chemical instruments and methods, applications, agriculture, etc., can solve the problem of crop areas that cannot adapt to high precipitation, the tensile strength and water resistance of liquid mulch are not strong, and the viscosity of biodegradable liquid mulch is formed. Low problems, to achieve the effect of enhancing viscosity, non-toxic side effects, and improving strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Before the production of liquid agricultural mulch film, take the following raw materials according to the weight ratio: 50 parts of sweet potato starch, 30 parts of industrial alcohol, 25 parts of white sugar, 20 parts of chitin, 15 parts of polyacrylamide, 15 parts of sodium fatty acid , 12 parts of polyurethane water-based resin, 10 parts of green pigment agent, 5 parts of barium stearate, 5 parts of water retaining agent, 2 parts of crosslinking agent SAC-100, 3 parts of magnesium aluminum hydrotalcite, 1 part of Surfactant, 6 parts soil conditioner and 1500 parts water.

[0018] The production method of the liquid agricultural mulch film: ① Take 400 parts of the mass of aqueous solution into a stainless steel reaction tank, then add 50 parts of sweet potato starch and 25 parts of white sugar, use a steam boiler to heat, stir while heating, and gelatinize at 70 ° C for 30 Minutes, into a transparent and viscous starch paste;

[0019] ② Then add 30 parts of industri...

Embodiment 2

[0025] Before the production of liquid agricultural mulch film, take the following raw materials according to the weight ratio: 55 parts of sweet potato starch, 35 parts of industrial alcohol, 30 parts of white sugar, 25 parts of chitin, 20 parts of flocculant 3630S, 18 parts of polyethylene Alcohol, 15 parts of polyurethane water-based resin, 15 parts of green pigment agent, 10 parts of barium stearate, 8 parts of water retaining agent, 6 parts of crosslinking agent SAC-100, 4 parts of magnesium aluminum hydrotalcite, 2 parts of surfactant, 8 parts of soil conditioner and 2000 parts of water.

[0026] The production method of the liquid agricultural mulch film: ① Take 500 parts of aqueous solution by mass and add it to a stainless steel reaction tank, then add 55 parts of sweet potato starch and 30 parts of white sugar, use a steam boiler to heat, stir while heating, and gelatinize at 70°C for 30 Minutes, into a transparent and viscous starch paste;

[0027] ② Then add 35 pa...

Embodiment 3

[0033] Before the production of liquid agricultural mulch film, take the following raw materials according to the weight ratio: 60 parts of sweet potato starch, 40 parts of industrial alcohol, 40 parts of white sugar, 30 parts of chitin, 25 parts of flocculant 3630S, 20 parts of sodium fatty acid , 20 parts of polyurethane water-based resin, 20 parts of green pigment agent, 15 parts of barium stearate, 10 parts of water retaining agent, 10 parts of crosslinking agent SAC-100, 5 parts of magnesium aluminum hydrotalcite, 3 parts of Surfactant, 10 parts soil conditioner and 2500 parts water.

[0034]The production method of the liquid agricultural mulch film: ① Take 600 parts of the mass of aqueous solution into a stainless steel reaction tank, then add 60 parts of sweet potato starch and 40 parts of white sugar, heat with a steam boiler, stir while heating, and gelatinize at 70 ° C for 30 Minutes, into a transparent and viscous starch paste;

[0035] ② Then add 40 parts of indu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com