A lithium-ion battery positive electrode material iron manganese magnesium lithium phosphate and preparation method thereof

A technology of iron, manganese, magnesium, lithium and lithium ion batteries, which is applied in the field of materials, can solve problems such as poor electrical conductivity, and achieve the effects of improved electrochemical performance, good safety, and excellent electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

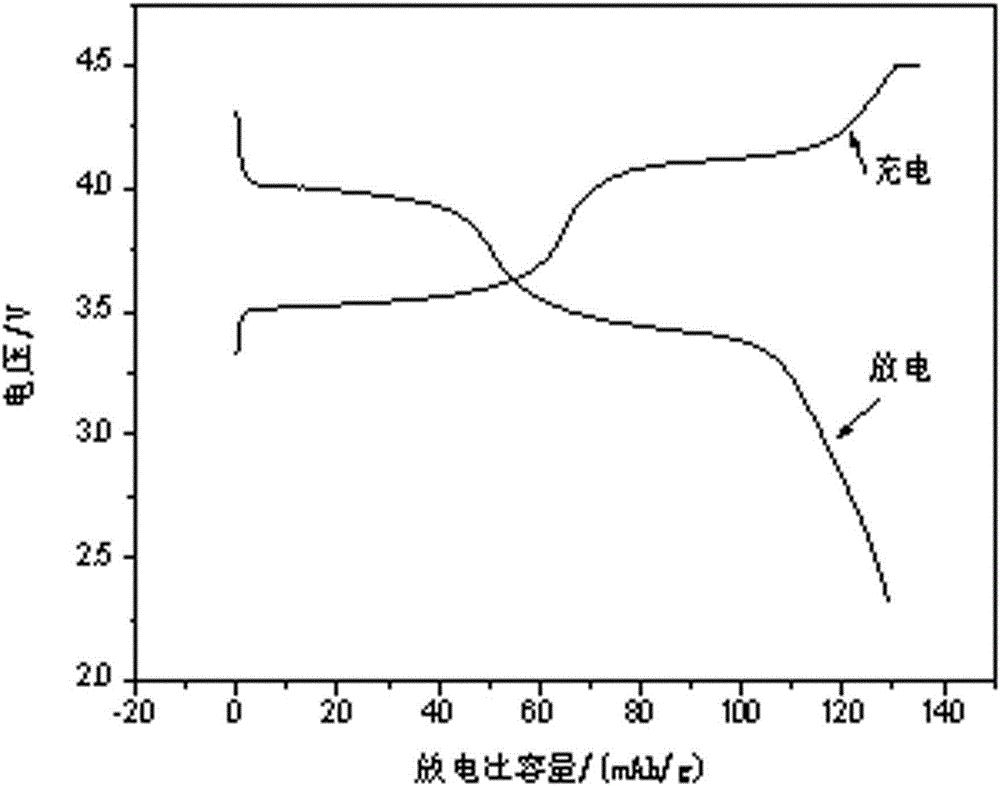

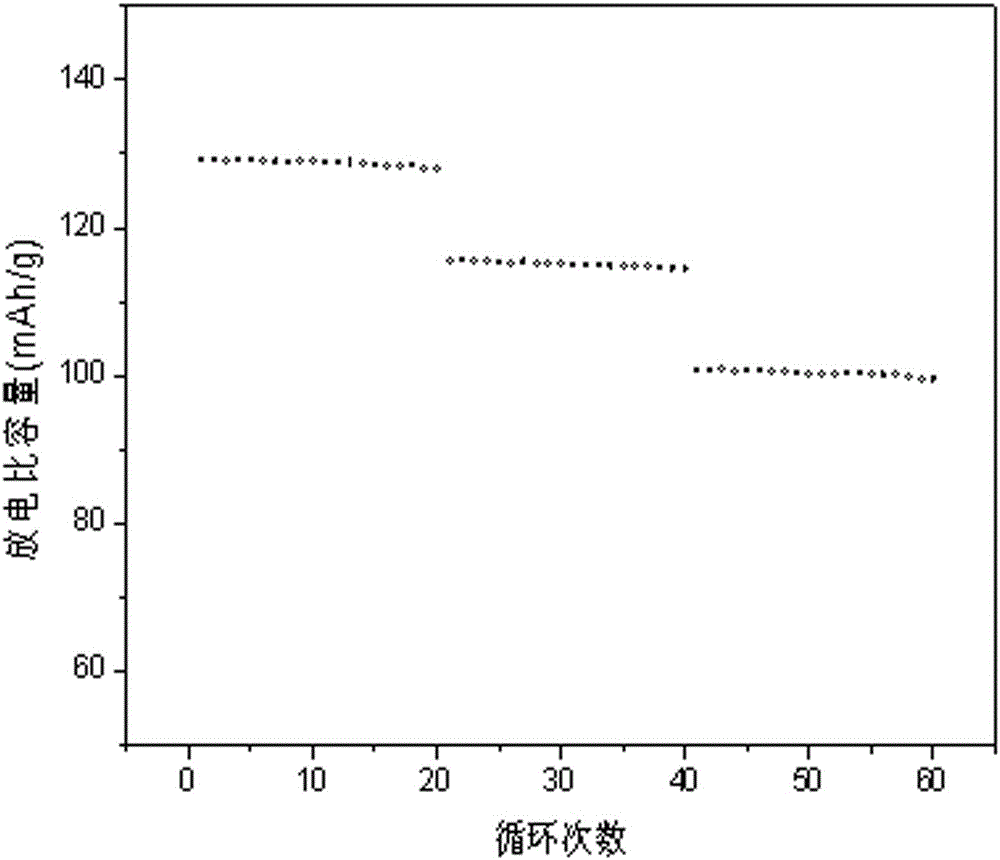

[0022] Weigh a certain amount of lithium carbonate, ferric nitrate, manganous acetate, magnesium acetate, and ammonium dihydrogen phosphate at a molar ratio of 1.05:0.5:0.45:0.05:1, then add glucose with a mass fraction of 13% and ball mill it in a ball mill for 2 hours. The uniformly mixed iron, manganese, magnesium, and lithium precursors were put into a microwave oven, and after 5 minutes of microwave treatment, they were left to be calcined. Control the heating rate at 10°C / min, calcinate the compounded precursor powder at 650°C for 12h under the protection of nitrogen atmosphere, and cool to room temperature with the furnace to obtain carbon-coated LiFe 0.5 mn 0.45 Mg 0.05 PO 4 Cathode material.

[0023] The prepared lithium manganese magnesium phosphate is used as the positive electrode material of the lithium ion battery, acetylene black is used as the conductive agent, and polyvinylidene fluoride is used as the binder to make the positive electrode sheet, and metal ...

Embodiment 2

[0025] Weigh a certain amount of lithium carbonate, iron phosphate, manganous acetate, magnesium oxide, and ammonium dihydrogen phosphate at a molar ratio of 1.1:0.5:0.45:0.05:1, then add starch with a mass fraction of 10% in a ball mill for 1 hour, and mix The uniform iron, manganese, magnesium, and lithium precursors were placed in a microwave oven, and after 10 minutes of microwave compounding treatment, they were left to be calcined. Control the heating rate at 11°C / min, calcinate the compounded precursor powder at 750°C for 10 hours under the protection of nitrogen atmosphere, and cool to room temperature with the furnace to obtain carbon-coated LiFe 0.5 mn 0.45 Mg 0.05 PO 4 Cathode material.

Embodiment 3

[0027]Weigh a certain amount of lithium carbonate, iron oxide, manganese carbonate, magnesium acetate, and ammonium dihydrogen phosphate at a molar ratio of 1.08:0.5:0.45:0.05:1, then add 8% sucrose in a ball mill for 5 hours, and mix well The final iron, manganese, magnesium, and lithium phosphate precursors were put into a microwave oven, and after 16 minutes of microwave compounding treatment, they were left to be calcined. Control the heating rate at 8°C / min, calcinate the compounded precursor powder at 800°C for 8 hours under the protection of nitrogen atmosphere, and cool to room temperature with the furnace to obtain carbon-coated LiFe 0.5 mn 0.45 Mg 0.05 PO 4 Cathode material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com