Preparation method for micro-strip ceramic antenna

A ceramic antenna and microstrip technology, which is applied in the field of preparation of microstrip ceramic antennas, can solve the problems that cannot meet the development direction of microstrip antennas, and achieve the effects of avoiding processing difficulties, reducing material and design costs, and easy demoulding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

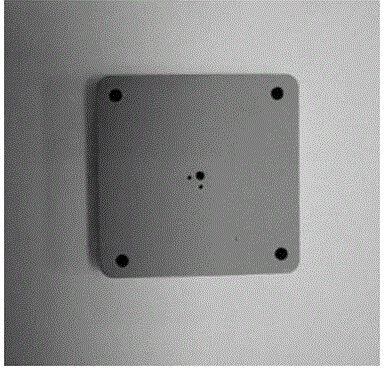

Image

Examples

Embodiment 1

[0024] The preparation method of the microstrip ceramic antenna of the present embodiment comprises the following steps:

[0025] First prepare 0.93(Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 ] Powder: according to chemical formula 0.93 (Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 Weigh zinc oxide, magnesium hydroxide, titanium oxide and calcium carbonate, add the weighed raw materials into a ball mill tank, conduct wet ball milling with absolute ethanol as a medium for 8 hours, then dry them, and heat them at 1200°C for 4 hours to obtain them. Then weigh 99.4wt% [0.93(Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 ], 0.3wt%CuO and 0.3wt%La 2 o 3 , the above three raw materials are ball milled in a ball mill for 12 hours and then dried to obtain ceramic powder.

[0026] 1) Prepare a mixture of water and ethylene glycol at a molar ratio of 3:1, add ceramic powder to the mixture of water and ethylene glycol, the ceramic powder accounts for 60% of the total volume, and obtain a ceramic powder...

Embodiment 2

[0033] The preparation method of the microstrip ceramic antenna of the present embodiment comprises the following steps:

[0034] First prepare 0.93(Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 ] Powder: according to chemical formula 0.93 (Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 Weigh zinc oxide, magnesium hydroxide, titanium oxide and calcium carbonate, add the weighed raw materials into a ball mill jar and conduct wet ball milling with absolute ethanol as a medium for 12 hours, then dry them, and heat them at 1000°C for 2 hours to obtain them. Then weigh 98.5wt%[0.93(Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 ], 0.7wt%CuO and 0.8wt%La 2 o 3 , the above three raw materials are ball milled in a ball mill for 8 hours and then dried to obtain ceramic powder.

[0035] 1) Prepare a mixture of water and ethylene glycol at a molar ratio of 1:1, add ceramic powder into the mixture of water and ethylene glycol, the ceramic powder accounts for 40% of the total volume, and obtain a ceramic pow...

Embodiment 3

[0042] The preparation method of the microstrip ceramic antenna of the present embodiment comprises the following steps:

[0043] First prepare 0.93(Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 ] Powder: according to chemical formula 0.93 (Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 Weigh zinc oxide, magnesium hydroxide, titanium oxide and calcium carbonate, add the weighed raw materials into a ball mill tank and conduct wet ball milling with absolute ethanol as a medium for 11 hours, then dry them, and heat them at 1100°C for 3 hours to obtain them. Then weigh 99.0wt% [0.93(Mg 0.97 Zn 0.03 )TiO 3 -0.07CaTiO 3 ], 0.5wt%CuO and 0.5wt%La 2 o 3 , the above three raw materials are ball milled in a ball mill for 10 hours and then dried to obtain ceramic powder.

[0044] 1) Prepare a mixture of water and ethylene glycol at a molar ratio of 2:1, add ceramic powder to the mixture of water and ethylene glycol, the ceramic powder accounts for 50% of the total volume, and obtain a ceramic po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com