Soil in-situ repairing agent used for synchronous treating heavy metal pollution and organic pollution

An in-situ remediation agent and a technology for polluted soil, applied in the restoration of polluted soil, organic fertilizers, soil conditioning materials, etc., can solve the problems of limited application, long repair period, secondary pollution, etc. Strong water permeability and the effect of reducing the content of heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Preparation of soil remediation agent

[0037] 1) Take 100kg of Hangjin 2# soil, add 10kg of activated carbon, 20kg of cement (Portland cement), 2kg of organic flocculant (polydimethyldiallylammonium chloride) and 15kg of soil bacteria (Pseudomonas aeruginosa), formulated as mixture A;

[0038] 2) Take 16 kg of sodium thiosulfate, 16 kg of iron oxide and 32 kg of alkali metal carbonate (sodium carbonate) and mix them uniformly to prepare mixture B;

[0039] 3) According to the ratio of mixture B: mixture A of 20:80, add the corresponding proportion of mixture B into mixture A, and mix evenly to prepare the soil remediation agent.

[0040] (2) Soil remediation treatment

[0041] After applying the soil remediation agent with a thickness of 1 cm on the surface of the heavy metal-contaminated soil, the 20 cm thick soil on the surface of the contaminated soil was mixed evenly with the applied soil remediation agent by tilling.

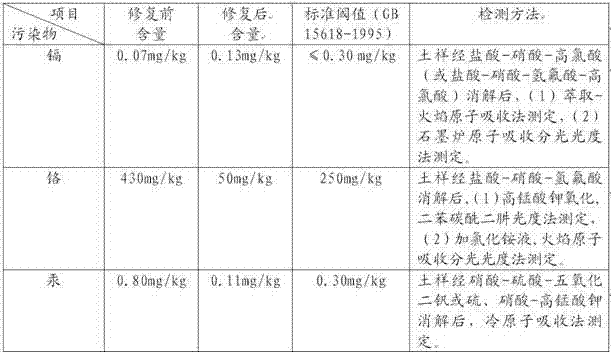

[0042] One week later, heavy metals su...

Embodiment 2

[0054] (1) Preparation of soil remediation agent

[0055] 1) Take 100kg of Hangjin 2# soil, add 20kg of activated carbon, 35kg of cement (high alumina cement), 4kg of organic flocculant (polydimethyldiallylammonium chloride) and 25kg of soil bacteria (Bacillus ), mix well, and prepare mixture A;

[0056] 2) Take 16kg of sodium thiosulfate, 16kg of iron oxide, 48kg of alkali metal carbonate (calcium carbonate) and 56kg of aluminum sulfate, mix them evenly, and prepare mixture B;

[0057] 3) According to the ratio of mixture B: mixture A mass ratio of 30:70, add the corresponding proportion of mixture B into mixture A, and mix evenly to prepare the soil repair agent.

[0058] (2) Soil remediation treatment

[0059] After applying the soil remediation agent with a thickness of 3 cm on the surface of the heavy metal-contaminated soil, the soil with a thickness of 20 cm on the surface of the contaminated soil was mixed evenly with the applied soil remediation agent by plowing.

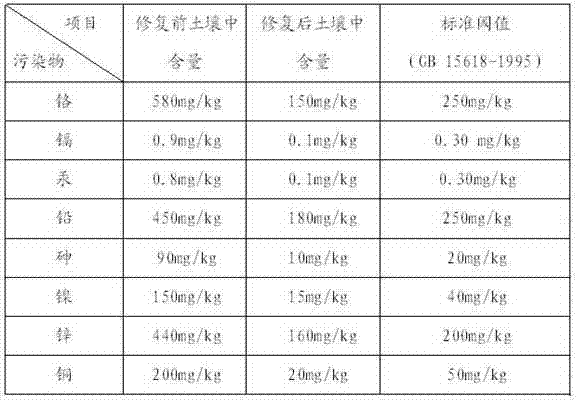

...

Embodiment 3

[0067] (1) Preparation of soil remediation agent

[0068] 1) Take 100kg of Hangjin 2# soil, add 30kg of activated carbon, 50kg of cement (25kg of fly ash cement and 25kg of calcium aluminate cement), and 5kg of organic flocculant (polydimethyldiallyl chloride ammonium) and 10kg of soil bacteria (subtilis) to prepare mixture A;

[0069] 2) Take 16kg of sodium thiosulfate, 16kg of iron oxide, 96kg of alkali metal carbonate, 80kg of aluminum sulfate and 16kg of alkali metal carbonate (magnesium carbonate) and mix them uniformly to prepare mixture B;

[0070] 3) According to the ratio of mixture B: mixture A mass ratio of 25:75, add the corresponding proportion of mixture B into mixture A, and mix evenly to prepare the soil remediation agent.

[0071] (2) Soil remediation treatment

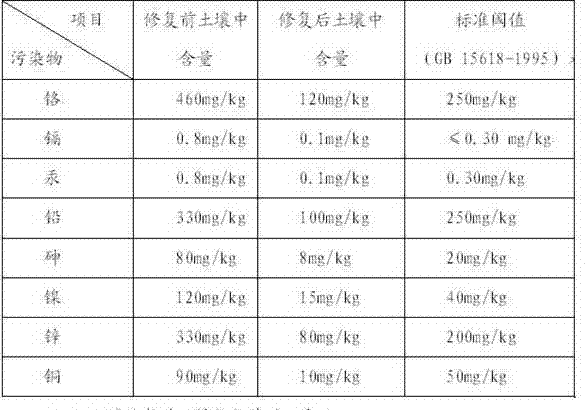

[0072] After applying the soil remediation agent with a thickness of 5 cm on the surface of the heavy metal-contaminated soil, the soil with a thickness of 20 cm on the surface of the contaminated s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com