Lignin-based starlike thermoplastic elastomer and preparation method thereof

A thermoplastic elastomer, lignin-based technology, applied in the field of star polymers of natural compounds, which can solve the problems of chemical modification of lignin, poor structural compatibility, limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A preparation method of a lignin-based star-shaped thermoplastic elastomer polymer, the steps: (1) react lignin with 2-bromoisobutyryl bromide to synthesize a lignin ATRP macroinitiator; (2) synthesize a hard monomer (such as methyl methacrylate), soft monomer (such as butyl acrylate), lignin ATRP macromolecular initiator, catalyst and ligand, and good reaction solvent are added to the reaction bottle, fully stirred and dissolved, and frozen and pumped three times The oxygen in the mixed solution is removed by the cycle process of vacuum and nitrogen filling. After reacting for 4-48 hours under the condition of 55-110 ° C, the methanol / water mixture is used as the precipitating agent, and the collected precipitate is filtered and dried to obtain UV-absorbing Properties and thermoplastic elastomer properties of lignin-based star polymers.

[0030] Lignin is alkaline lignin.

[0031] In the step (1), a catalyst is also added, which is 4-dimethylaminopyridine, N,N-lutidin...

Embodiment 1

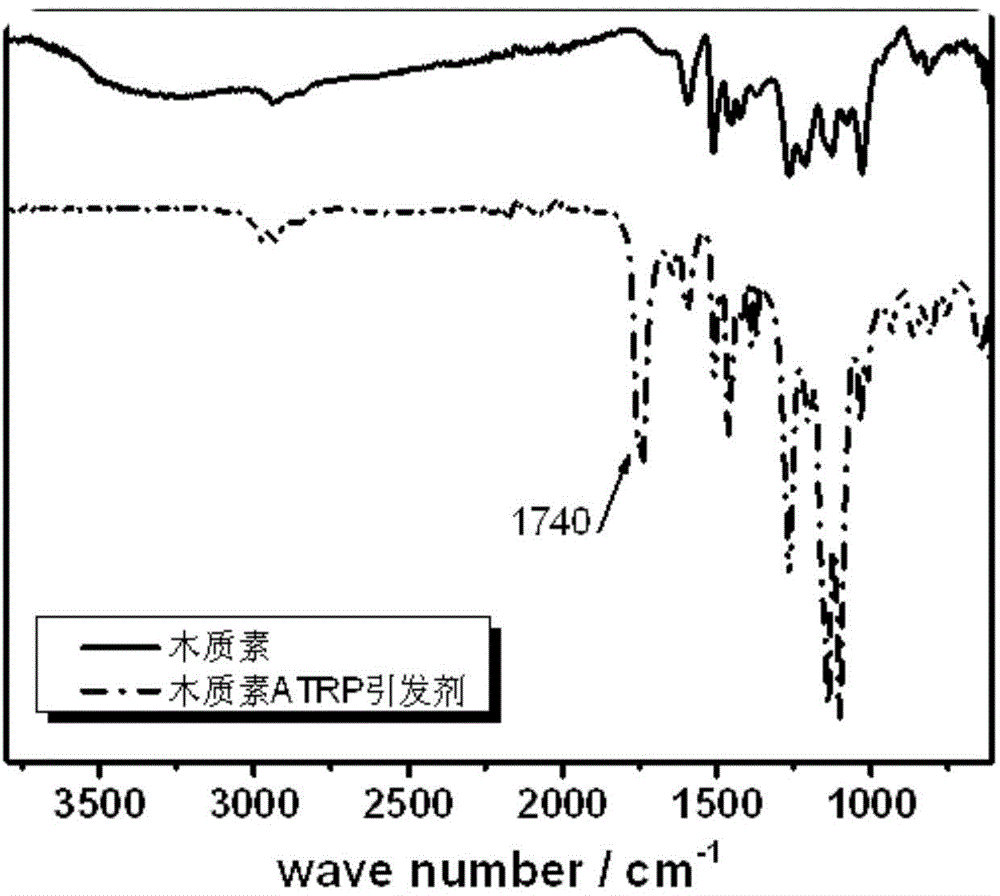

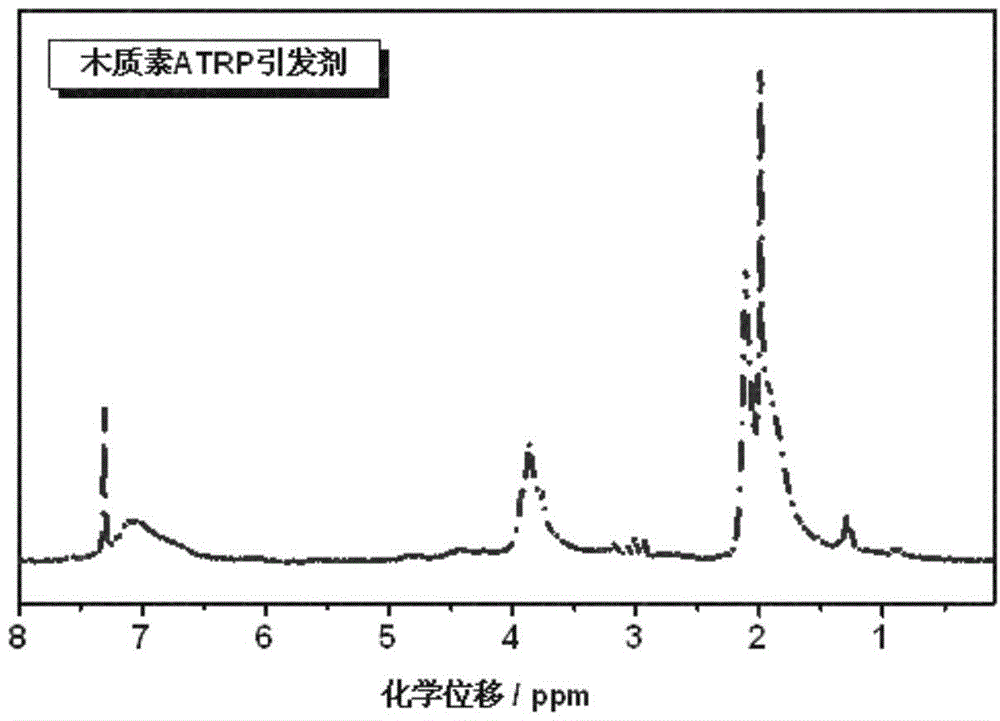

[0039] (1) Synthesis of lignin macromolecular initiator: the basic lignin of 1.0g (hydroxyl content 9.01mmol), 0.89g (7.28mmol) of 4-diaminopyridine (DMAP) was added in the there-necked flask containing 40ml DMF, Stir to dissolve in an ice-water bath, then add 0.92ml of 2-bromoisobutyryl bromide (7.28mmol) dropwise, stir at room temperature for 12h, then raise the temperature to 50°C to continue the reaction for 12h. Finally, the reaction solution is poured into a large amount of distilled water, filtered, washed with water, and dried to constant weight to obtain a powdery lignin macromolecular initiator, and the trigger point content is 3.07mmolBr / g. The structural diagram of the lignin macromolecular initiator is as follows figure 1 with figure 2

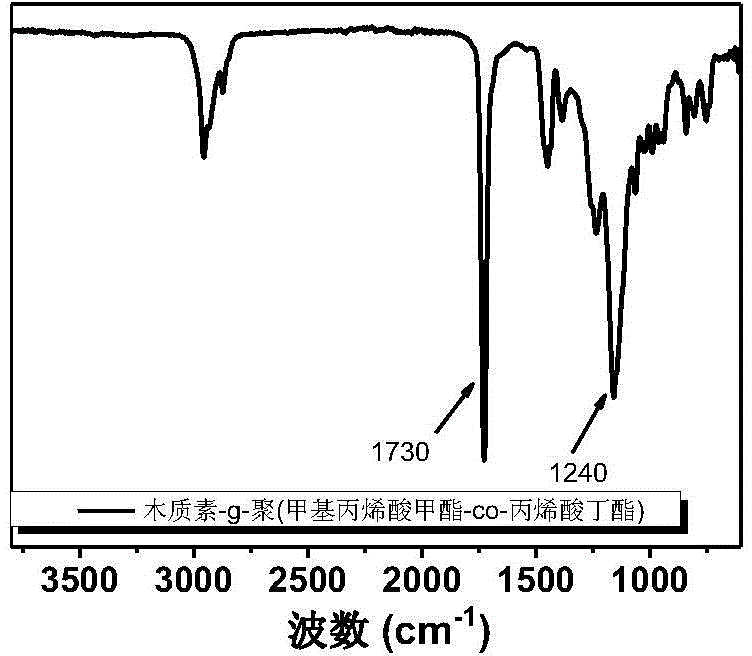

[0040] (2) Synthesis of lignin-g-(methyl methacrylate-co-butyl acrylate) graft copolymer: [methyl methacrylate+butyl acrylate] / [initiator] / [catalyst] / [ Ligand]=(10+10):1:1:1

[0041] Lignin macromolecular initiator 0.0100g (0....

Embodiment 2

[0043] [methyl methacrylate+butyl acrylate] / [initiator] / [catalyst] / [ligand]=(40+60):1:1:1

[0044] Lignin macromolecular initiator (prepared in Example 1) 0.0100g (0.0307mmolBr), ligand N,N,N,N,N-pentamethyldiethylenetriamine (PMDETA) 8.12μL (0.0307mmol ), methyl methacrylate 0.1107 (1.228mmol), butyl acrylate 0.2241g (1.842mmol) were dissolved in 2mlTHF, and the oxygen in the mixed solution was removed through three cycles of freezing, vacuuming, and nitrogen charging. At the same time, Add 0.0054g (0.0307mmol) Cu(I)Br into the polymerization bottle, and put it in an oil bath at 80°C for 24h. After the reaction, the reactant was passed through a neutral aluminum oxide column to remove the copper catalyst, dropped into a large amount of methanol for precipitation, filtered to collect the precipitate, and finally dried in a vacuum oven at room temperature for 24 hours. The total conversion rate of monomer is 66% (weight method), Mn=12500g / mol (GPC)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com