Photo-catalytic oxidation desulfurization method and catalyst for diesel or gasoline

A desulfurization catalyst, photocatalytic oxidation technology, applied in physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, chemical instruments and methods, etc. The problems of high hole-electron pair recombination rate and low photocatalytic efficiency of photocatalyst can achieve the effect of improving photocatalytic oxidation desulfurization performance, low operating cost, and environmental friendly operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-5

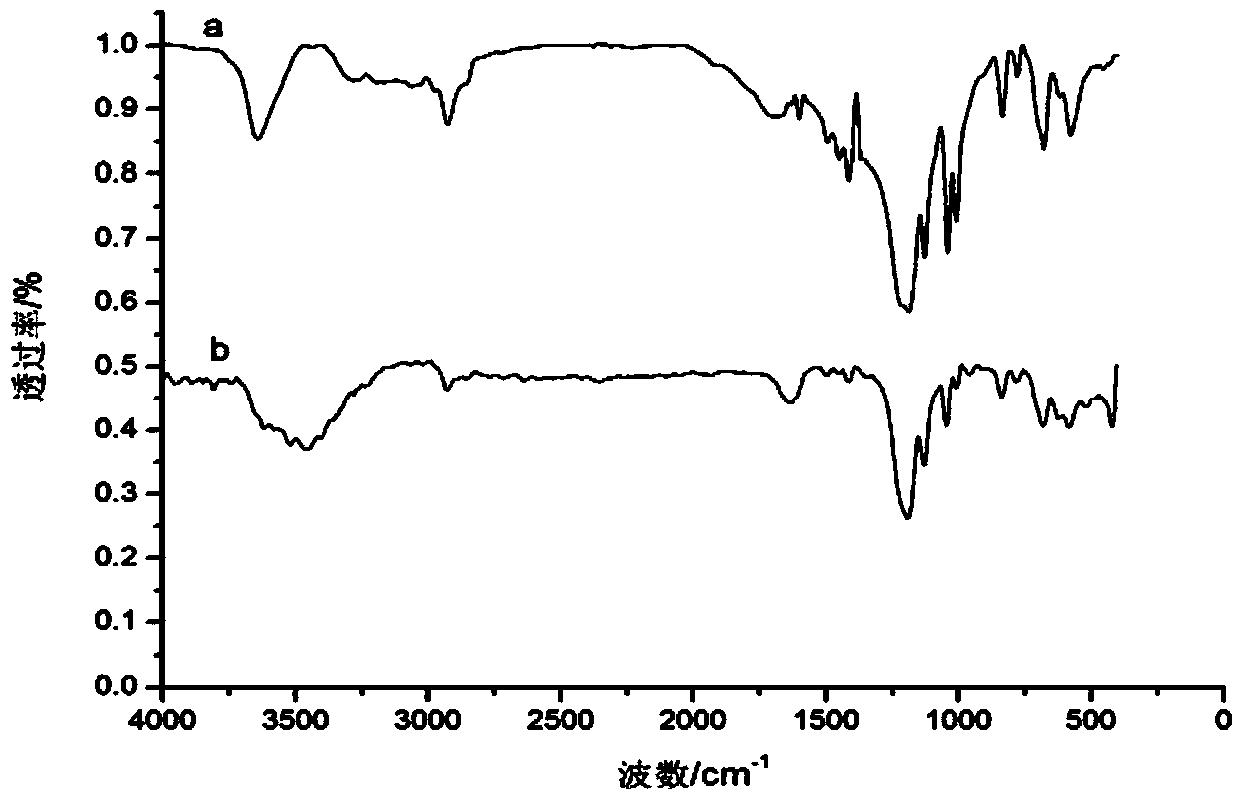

[0024] Embodiment 1-5: Preparation method of diesel or gasoline photocatalytic oxidation desulfurization catalyst

[0025] Wash the finished macroporous polystyrene resin D001-cc with ethanol and deionized water several times to remove impurities. After immersing in 0.1 mol / L sulfuric acid solution for 24 h, it was washed with deionized water until the pH value of the solution remained constant, and dried in a drying oven at 60 °C to constant weight.

[0026] Immerse a 100 mL two-necked glass reaction bottle equipped with mechanical stirring in an ice-salt bath at -25 °C, add 100 mL of 1,1,2-trifluorotrichloroethane (F113) under slow stirring, and then add 8.0 mL of 25 wt% NaOH aqueous solution and 1 mL of 30 wt% H 2 o 2 , after stirring for 5 min, 4.6496 g of heptafluorobutyryl chloride was added quickly, the reaction was carried out for 2 min, the stirring was stopped to allow the reaction mixture to separate completely, and the lower oil layer was collected and washed w...

Embodiment 6-10

[0030] Diesel / gasoline photocatalytic oxidation desulfurization experiment, the experimental conditions are: diesel oil 10 mL, catalyst dosage is 1.0% of diesel mass, reaction temperature is 80 ℃, phosphotungstic acid loading is 10 wt%, oxygen flow rate is 150 mL / min , 125 w ultraviolet light source, 90% NMP aqueous solution as the extraction agent, and the ratio of agent to oil is 1:1, change the reaction time, and investigate the influence of the reaction time on the desulfurization rate when the reaction time is 1h, 1.5h, 2h, 2.5h, and 3h respectively. The experimental results are shown in Table 1.

[0031] Table 1 Effect of reaction time on desulfurization effect

[0032] Reaction time / h 1 1.5 2 2.5 3 Desulfurization rate / % 43.53 44.27 52.10 54.52 55.72

[0033] It can be seen that the desulfurization rate gradually increases with the prolongation of the reaction time, and a sudden change occurs after 1.5 h, and the desulfuriz...

Embodiment 11-14

[0035] Diesel / gasoline photocatalytic oxidation desulfurization experiment, the experimental conditions are: diesel oil 10 mL, the catalyst dosage is 1 wt% of the diesel mass, the reaction time is 2 h, the loading of phosphotungstic acid is 10 wt%, and the oxygen flow rate is 150 mL / min , 125 w ultraviolet light source, 90% NMP aqueous solution as the extraction agent, and the ratio of agent to oil is 1:1, the reaction temperature is changed, and the influence of the reaction temperature on the desulfurization rate of 30°C, 50°C, 70°C, and 90°C is investigated. The experiment The results are shown in Table 2.

[0036] Table 2 Effect of reaction temperature on desulfurization effect

[0037] Reaction temperature / ℃ 30 50 70 90 Desulfurization rate / % 42.63 44.56 51.39 61.52

[0038] It can be seen that when the reaction temperature is lower than 90 ℃, the desulfurization rate increases gradually with the increase of the reaction temperature, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com