Method for preparing LED (light-emitting diode) broadband gradient fluorescent film by chemical solution coating

A chemical solution, gradient fluorescence technology, applied in chemical instruments and methods, liquid chemical plating, liquid phase epitaxial layer growth, etc., can solve the problems of non-uniform color temperature, difficult to reproduce and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

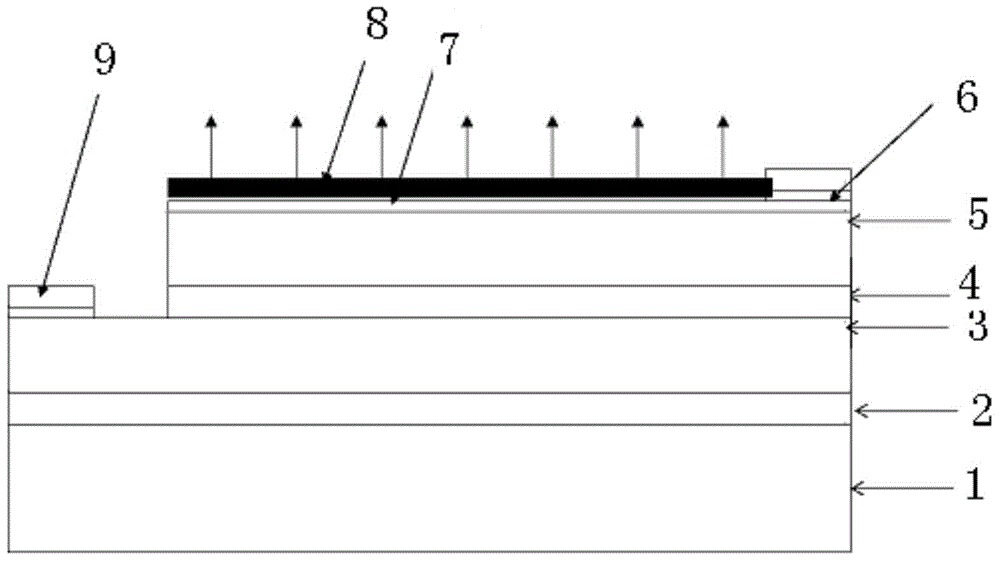

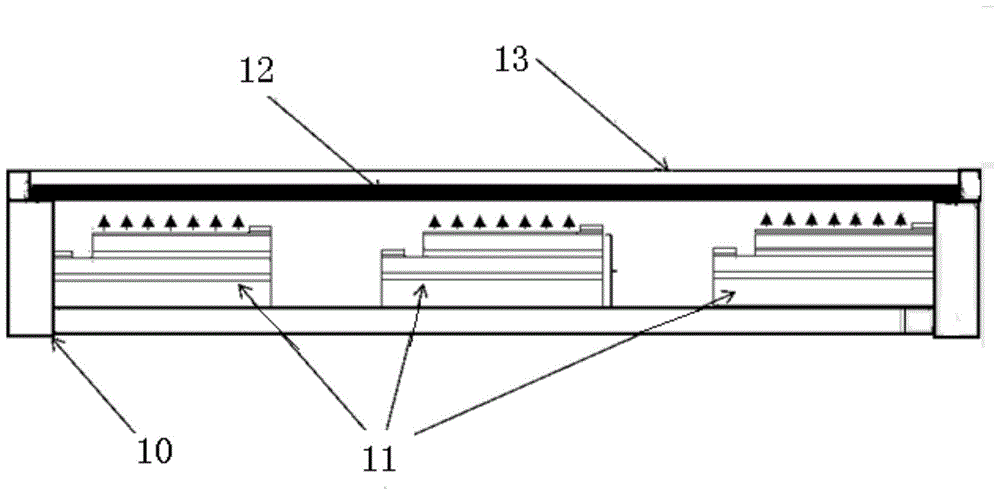

[0044] Example 1: Preparation of broadband gradient YAG fluorescent single crystal thin film by sol-gel method

[0045] 1.1YAG:Ce 3+ Preparation of sol: This step is to prepare the composition Y separately 2.94 al 2.5 Ga 2.5 o 12 : Ce 0.06 greenish fluorescent film, yellow Y 2.94 al 5 o 12 : Ce 0.06 and reddish Y 2.74 al 5 o 12 : Ce 0.06 +Gd 0.2Precursor sols for fluorescent thin films. Then, the three kinds of sols are used for epitaxial production in different combinations to form a broad-band gradient fluorescent single crystal thin film.

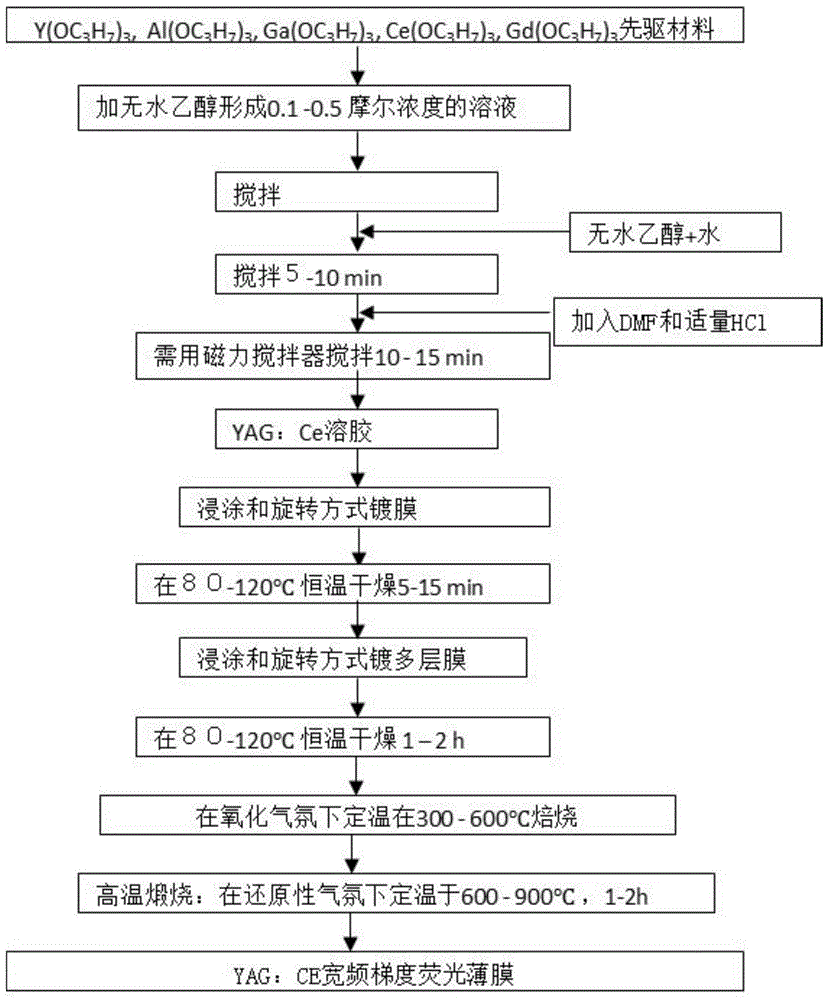

[0046] 1.2. Preparation of YAG:Ce by sol-gel method 3+ fluorescent film. Use metal alkoxides whose raw materials are Y, Al, Ga, Ce and Gd such as: Y(OC 3 h 7 ) 3 ,Al(OC 3 h 7 ) 3 ,Ga(OC 3 h 7 ) 3 , Ce(OC 3 h 7 ) 3 ,Gd(OC 3 h 7 ) 3 and absolute ethanol (EtOH, analytical grade); N, N-dimethylformamide (DMF, analytical grade); concentrated hydrochloric acid (analytical grade), deionized water.

[0047] The pr...

Embodiment 2

[0049] Example 2: Preparation of broadband gradient BSS fluorescent single crystal thin film by sol-gel method

[0050] 2.1 Raw materials: Analytical pure Ba, Sr, Si, Eu metal alkoxides such as: Ba(OC 3 h 7 ) 2 ,Sr(OC 3 h 7 ) 2 ,Si(OC 2 h 5 ) 2 ,Eu(OC 3 h 7 ) 3 , absolute ethanol (EtOH, analytical grade); N, N-dimethylformamide (DMF, analytical grade); concentrated hydrochloric acid (analytic grade), deionized water.

[0051] 2.2BSS:Eu 3+ Preparation of sol: This step is to prepare the composition as Ba 1.8 Sr 0.2 SiO 4 :Eu 0.06 Greenish fluorescent film, yellow Ba 0.5 Sr 1.5 SiO 4 :Eu 0.06 and reddish Ba 0.1 Sr 1.9 SiO 4 :Eu 0.2 Precursor sols for fluorescent thin films. Then, the three kinds of sols are used for epitaxial production in different combinations to form a broad-band gradient fluorescent single crystal thin film.

[0052] First put Ba, Sr, Si, Eu metal alkoxides such as: Ba(OC 3 h 7 ) 2 ,Sr(OC 3 h 7 ) 2 ,Si(OC 2 h 5 ) 2 ,Eu(OC 3...

Embodiment 3

[0054] Example 3: Preparation of Broadband Gradient YAG Fluorescent Single Crystal Thin Film by Organic Compound Decomposition Method

[0055] 3.1YAG:Ce 3+ Preparation of organic compound precursors: this step is to prepare the composition Y 2.94 al 2.5 Ga 2.5 o 12 : Ce 0.06 greenish fluorescent film, yellow Y 2.94 al 5 o 12 : Ce 0.06 and reddish Y 2.74 al 5 o 12 : Ce 0.06 +Gd 0.2 Precursor solution for fluorescent thin films. Then, the three kinds of solution gels with different compositions are used for epitaxial production according to different combination sequences to form a broad-band gradient fluorescent single crystal thin film.

[0056] 3.2 Preparation of YAG:Ce by decomposition of organic compounds 3+ fluorescent film. Use raw materials as Y, Al, Ga, Ce, organic compounds such as Gd: yttrium 2-ethylhexanoate [Y(C 7 h 15 COO) 3 ], aluminum 2-ethylhexanoate [Al(C 7 h 15 COO) 3 ], Gallium 2-ethylhexanoate [Ga(C 7 h 15 COO) 3 ], cerium 2-ethylhex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com