Preparation method for molecularly imprinted polymer microballoon with hydrophilic high-molecular brush

A hydrophilic polymer and molecular imprinting technology, which is applied in the fields of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problem that the brush density of hydrophilic polymers cannot be obtained and is difficult to obtain Problems such as MIP microspheres and complex polymerization systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

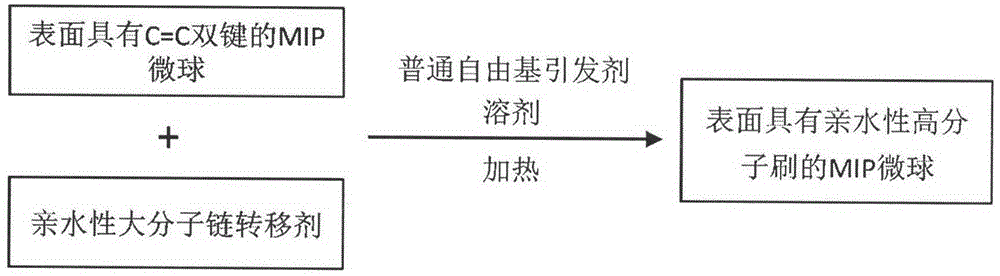

Method used

Image

Examples

example 1

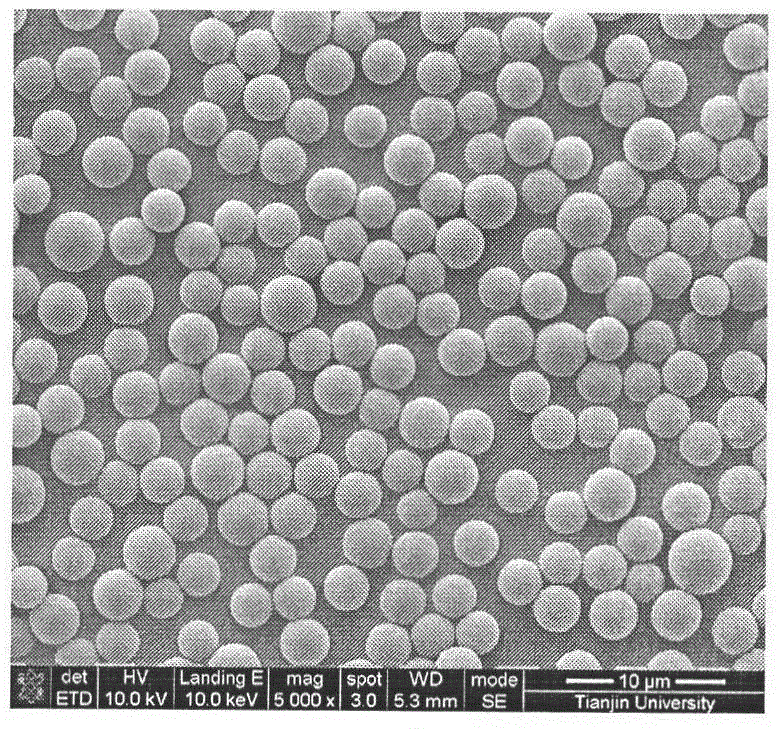

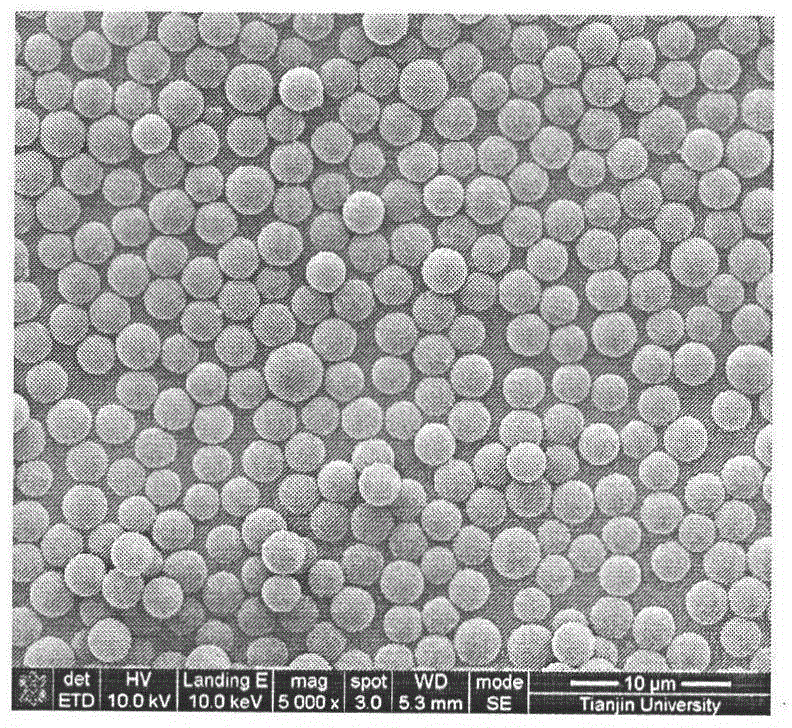

[0028] Add 150mg of MIP microspheres with 2,4-D as template (double bond content of 0.0408mmol / g) into an eggplant-shaped bottle containing 30mL of dimethylformamide, and then add 0.0736mmol of polyethylene glycol macromolecule Chain transfer agent (M n =5000) and 0.0238mmol of azobisisobutyronitrile (AIBN). After freezing and pumping five times to remove oxygen, the reaction system was sealed, placed in a 60°C constant temperature oil bath, reacted for 48 hours, and centrifuged at high speed to obtain the reaction product.

[0029] Surface grafted hydrophilic polyethylene glycol macromolecular brush (M n =5000) of the non-imprinted polymer microspheres.

example 2

[0031] 150mg of MIP microspheres with 2,4-D as template (double bond content of 0.0408mmol / g) were added to an eggplant-shaped bottle containing 30mL of dimethylformamide, and then 0.0736mmol of poly(N-isopropyl) Acrylamide) macromolecular chain transfer agent (M n,NMR = 10300) and 0.0238 mmol of azobisisobutyronitrile (AIBN). After freezing and pumping five times to remove oxygen, the reaction system was sealed, placed in a 60°C constant temperature oil bath, reacted for 48 hours, and centrifuged at high speed to obtain the reaction product.

[0032] Surface grafted hydrophilic poly(N-isopropylacrylamide) macromolecular brush (M n,NMR =10300) The process of non-imprinted polymer microspheres is the same as above.

example 3

[0034] Add 50mg of MIP microspheres (double bond content 0.0383mmol / g) with propranolol as template into an eggplant-shaped bottle containing 10mL dimethylformamide, and then add 0.0245mmol polyethylene glycol macromolecular chain transfer agent (M n =5000) and 0.0159mmol of azobisisobutyronitrile (AIBN). After freezing and pumping five times to remove oxygen, the reaction system was sealed, placed in a 60°C constant temperature oil bath, reacted for 48 hours, and centrifuged at high speed to obtain the reaction product.

[0035] Surface grafted hydrophilic polyethylene glycol macromolecular brush (M n =5000) The process of non-imprinted polymer microspheres is the same as above.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com