Flue gas desulfurizing device

A desulfurization device and flue gas technology, which is applied to the separation of dispersed particles, chemical instruments and methods, and separation methods, can solve the problems of high tail gas requirements, high flue gas conditions, and high operating costs, and achieve high adaptability to flue gas fluctuation performance, Avoid pipe blockage and avoid equipment corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

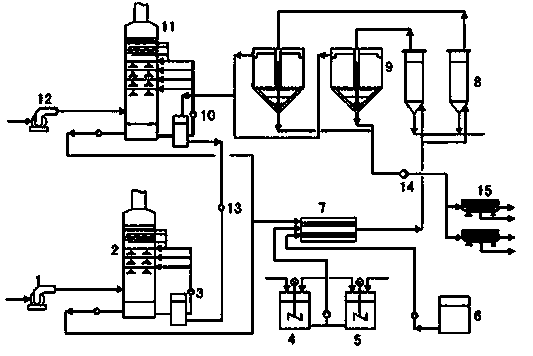

[0016] Specific embodiment: as shown in the figure is a schematic diagram of the flue gas desulfurization device of the present invention, in which the induced draft fan 1 introduces high concentration SO 2 The flue gas introduced by the induced draft fan 12 is low concentration SO 2 The flue gas first passes through the respective absorption towers 2 and 11 to realize the absorption of sulfur dioxide, the absorption liquid is pumped into the clear liquid pool, the absorption liquid in the clear liquid pool enters the pipeline reactor 7, and passes through the batching pool 4, 5 and the lye pool 6 at the same time The magnesium oxide slurry is mixed with sodium hydroxide with a mass fraction of 30%, reacted in the pipeline reactor 7 to generate highly soluble magnesium sulfite, and enters the power reactor 8 to further strengthen the reaction, and at the same time, the large amount of magnesium contained in the magnesium oxide is Particulate impurities and the generated magnes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com