Method for intensifying starting performance of anaerobic ammonia oxidation process by using ultrasonic wave

A technology of anammox and anammox bacteria, which is applied in the field of new wastewater biological denitrification technology, can solve the problems of long start-up period of anammox process, low growth rate of anammox bacteria, and high environmental sensitivity , to achieve the effect of enhancing the activity and the competitive advantage of the flora, shortening the start-up cycle and high biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

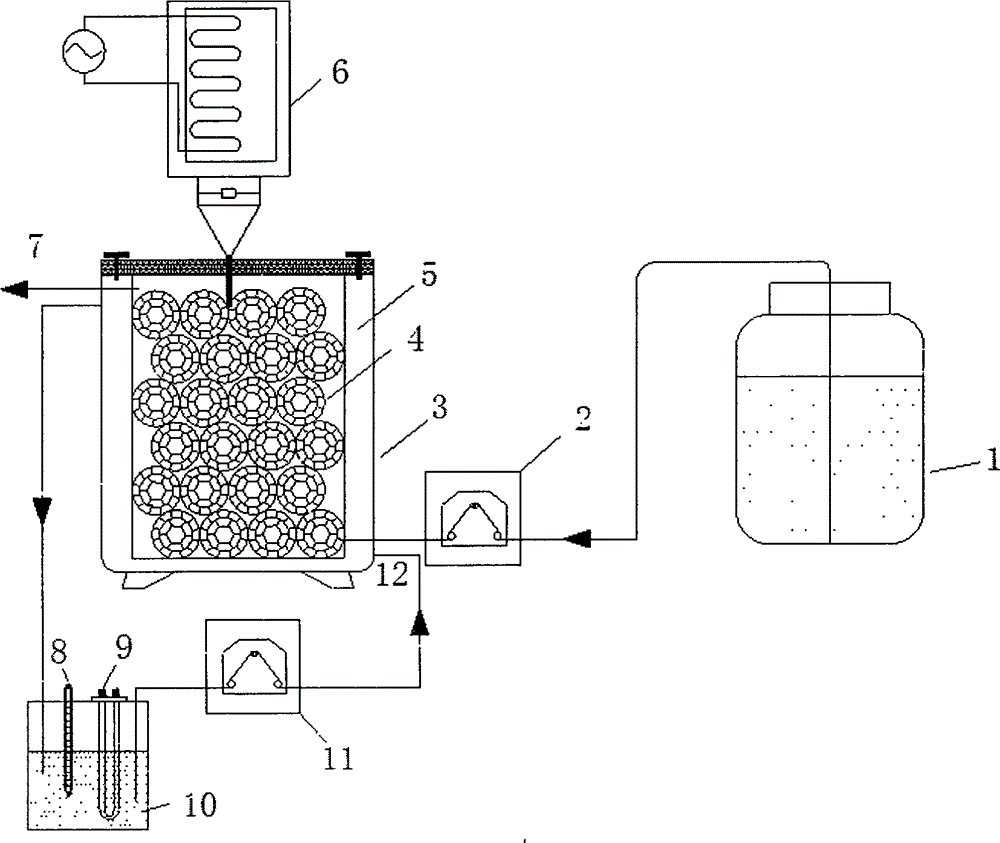

Embodiment 1

[0023] The aerobic activated sludge in the CASS tank of a municipal sewage treatment plant was used as the inoculum. The ratio of reactor height to inner diameter is 1.5, and the effective volume is 2.4L. Firstly, the fixed-bed reactor is filled with honeycomb polypropylene (PP) packing, the selected PP honeycomb packing has a diameter of 2.5 cm and a filling ratio of 85%. Then the collected aerobic activated sludge was rinsed 3 times with water. After rinsing, the sludge mixed liquor suspended solids concentration (MLSS) was 1.86g / L, and the mixed liquor volatile suspended solids concentration (MLVSS) was 1.53g / L. Take 2L of sludge mixture and inoculate it into the reactor. The influent is simulated wastewater, prepared according to the main components of the anammox bacteria culture medium, mainly containing ammonia nitrogen and nitrite nitrogen, and does not contain organic matter. With 95%Ar / 5%CO 2 The mixed gas is used to aerate the simulated wastewater for 10 minutes...

Embodiment 2

[0025]Nitrifying sludge from an aquaculture sewage treatment plant using A / O process was used as the inoculum. After 2 times of rinsing, the MLSS and MLVSS of the inoculum sludge were 2.16g / L and 1.63g / L, respectively. The selected PP honeycomb filler has a diameter of 1.5cm. The reaction temperature is 37°C, and the pH value is 7-7.8. During the operation of the device, the cultured sludge is subjected to ultrasonic irradiation twice a day, the frequency of each ultrasonic irradiation is 20kHz, and the intensity is 0.3w / cm 2 , the irradiation time is 5min. The remaining steps are the same as in Example 1. After 51 days of continuous operation, the anammox sludge is domesticated and mature, and the anammox process is successfully started.

Embodiment 3

[0027] Granular sludge from an upflow anaerobic sludge bed (UASB) was used as the inoculum. After one rinse, the MLSS and MLVSS of the inoculum sludge were 2.85g / L and 2.13g / L, respectively. The diameter of the selected PP honeycomb filler is 1cm. The pH value of the reactor mixture is 7.5-8. During the start-up process of the process, the cultured sludge is irradiated with ultrasound once a day, and the frequency used for each ultrasound irradiation is 50kHz, and the intensity is 0.7w / cm 2 , the irradiation time is 3min. The rest of the steps were the same as in Example 1. After 62 days of operation, the anammox process was started successfully, and the anammox sludge was domesticated and mature, and the anammox bacteria were the dominant bacteria in the sludge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com