Preparation method of RGD-modified subminiature superparamagnetic iron oxide nanoparticles

A technology of superparamagnetic iron oxide and nanoparticles, which can be used in preparations for in vivo tests, pharmaceutical formulations, emulsion delivery, etc., can solve problems such as no discovery, and achieve simple and easy operation, low raw material cost, high target tropism effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

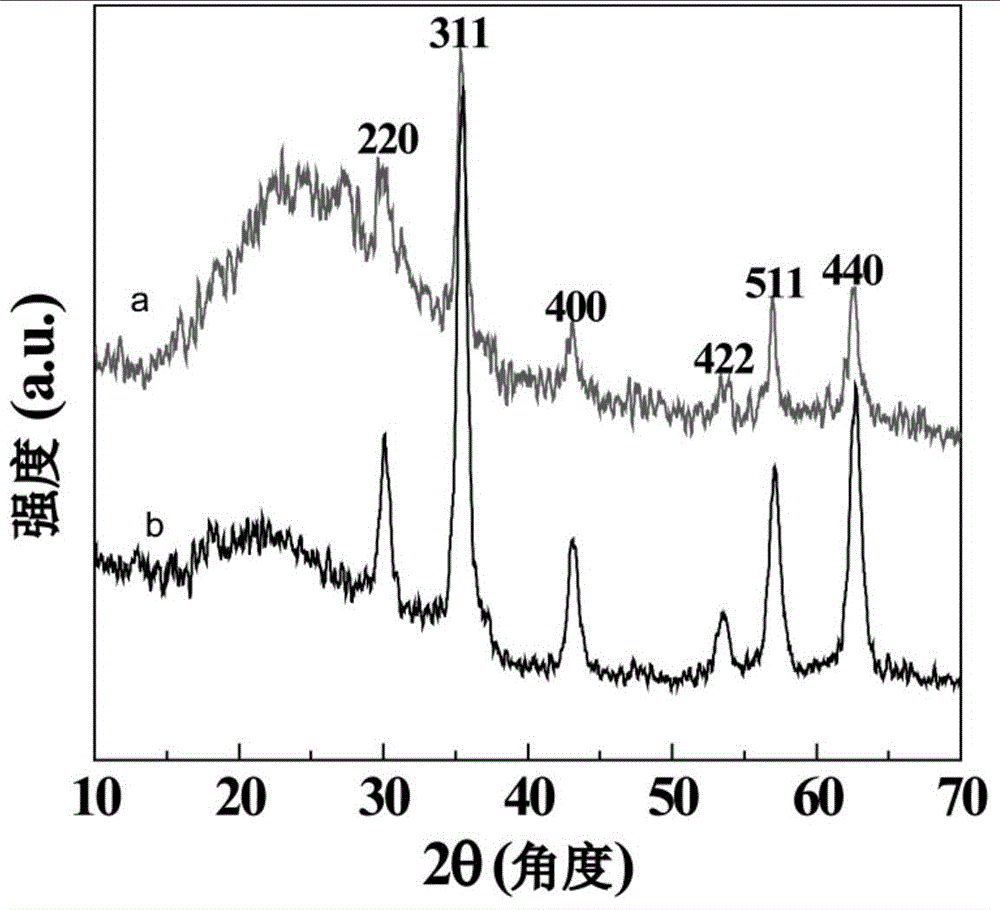

Embodiment 1

[0063] 1.30g FeCl 3 ·6H 2 O was dissolved in 20mL of ultrapure water, transferred to a 250mL three-necked flask and stirred; after blowing nitrogen for 15 minutes, dissolved 0.2g of sodium sulfite in 10mL of ultrapure water and added to the three-necked flask, and continued stirring for 30 minutes; then 0.5g of Aqueous solution of hyperbranched polyethyleneimine PEI and 2 mL of NH 3 ·H 2 O was also added to the three-necked flask, and stirred at 70°C for 30 minutes; then reacted at room temperature for 1.5 hours; after the reaction, the obtained black USPIO / PEI.NH 2 Magnetic separation, remove the supernatant, add an appropriate amount of ultra-pure water for ultrasonic dispersion, and then magnetic separation, repeat the ultra-pure water washing three times to remove impurities, and then re-disperse in 20mL ultra-pure water to obtain PEI-coated USPIO Nanoparticles (USPIO / PEI.NH 2 ). At the same time, bare USPIO was prepared as a control in the absence of PEI by the same ...

Embodiment 2

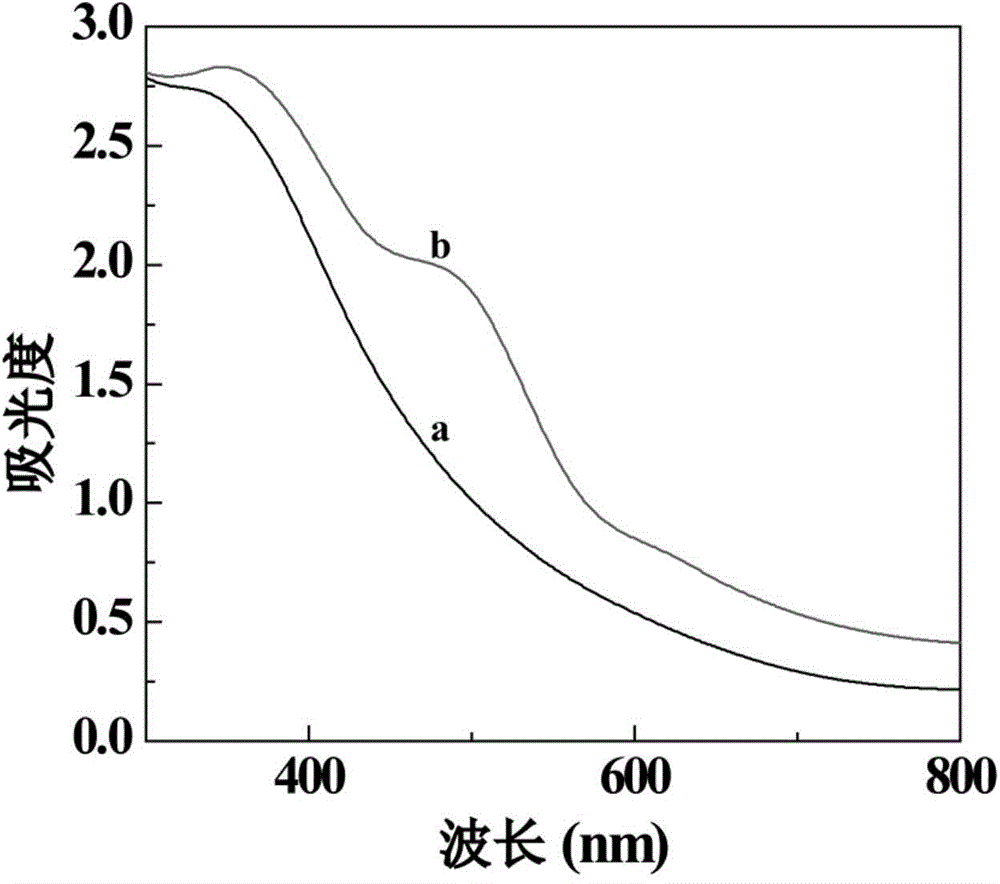

[0065] Take 20mL USPIO / PEI.NH 2 (154 mg) (Example 1) was washed with DMSO and redispersed in 20 mL of DMSO solution. Next, 2 mL of FI solution (3.6 mg) dissolved in DMSO was added to USPIO / PEI.NH 2 DMSO solution, stirred for 1 day, the product USPIO / PEI.NH 2 -FI is magnetically separated and washed with ultrapure water, then dispersed into water. Take 25μL USPIO / PEI.NH respectively 2 (Example 1), USPIO / PEI.NH 2 Put the aqueous solution of -FI in a 2mL centrifuge tube, then add 700μL ultrapure water to it, ultrasonically homogenize, and measure the ultraviolet absorption (see appendix figure 2 ). As can be seen from the figure, USPIO / PEI.NH 2 There is no obvious ultraviolet absorption peak at 400 to 600nm, while USPIO / PEI.NH 2 -FI has an obvious UV absorption peak at 500nm, which shows that FI has been successfully modified to USPIO / PEI.NH 2 nanoparticle surface.

Embodiment 3

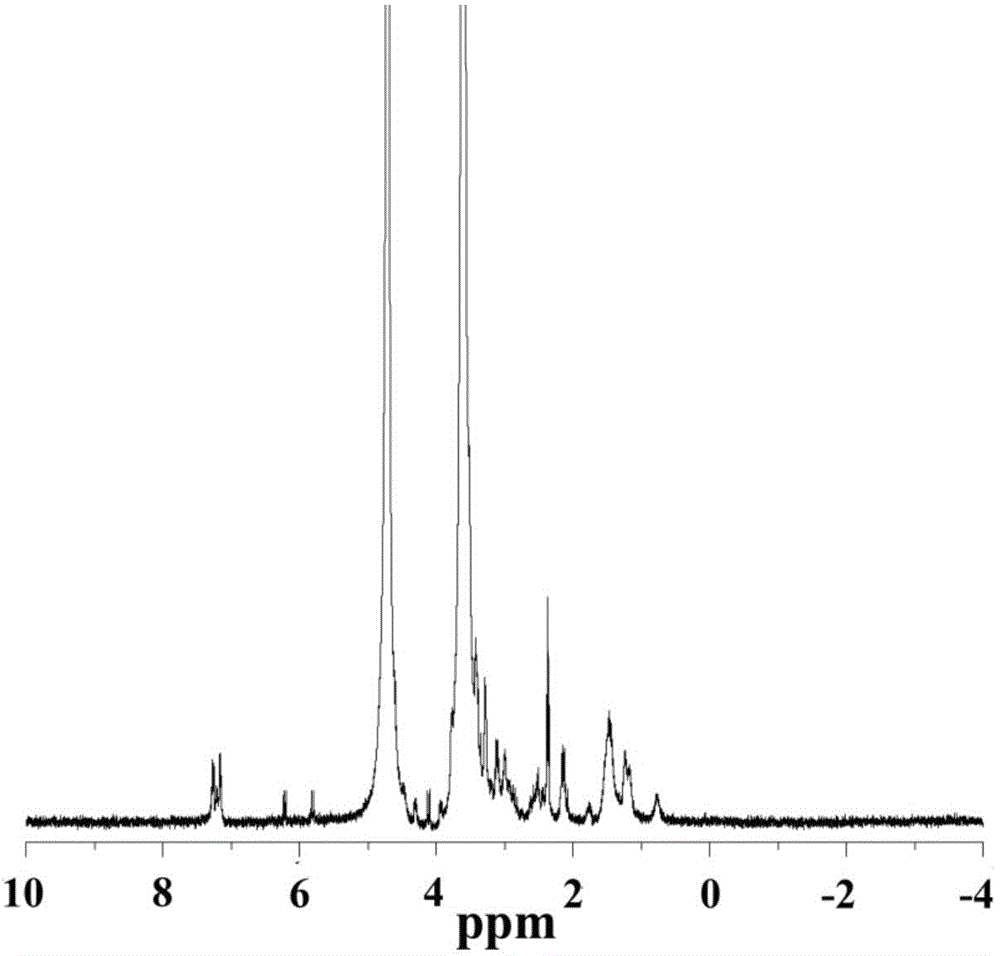

[0067] Mix 3.70mg 6-M with 20mg NH 2 -PEG-COOH was mixed in 5mL DMSO solution, stirred and reacted for 10 hours to obtain COOH-PEG-6-M; then 6.91mg RGD fully dissolved in 2mL DMSO was added dropwise to COOH-PEG-6-M In DMSO solution, stirred and reacted for 1 day, dialyzed with a dialysis bag with a molecular weight cut-off of 1000 for 3 days, and then vacuum freeze-dried to obtain COOH-PEG-RGD. The COOH-PEG-RGD that gets 3mg synthesis is dissolved in deuterated DMSO and carries out nuclear magnetic resonance analysis ( 1 H NMR) (see attached image 3 ). It can be seen from the figure that the spectral peaks at 7.3 and 7.4ppm prove that RGD is successfully connected to PEG, and it can be seen from the peak area integration that 0.5 RGD is connected to each PEG.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com