Construction and application of xylitol high-temperature and high-yield engineered strains

An engineering and xylose technology, applied in the biological field, can solve the problems of low rate, low xylitol concentration and efficiency, and a production rate of only 0.24g.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

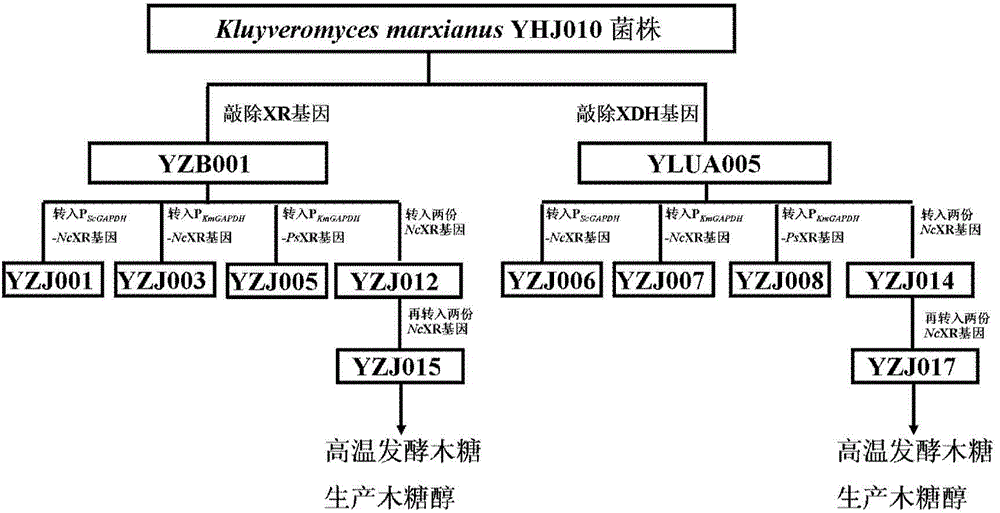

[0071] Embodiment 1. Preparation of bacterial strains:

[0072] 1. Acquisition of various XR genes:

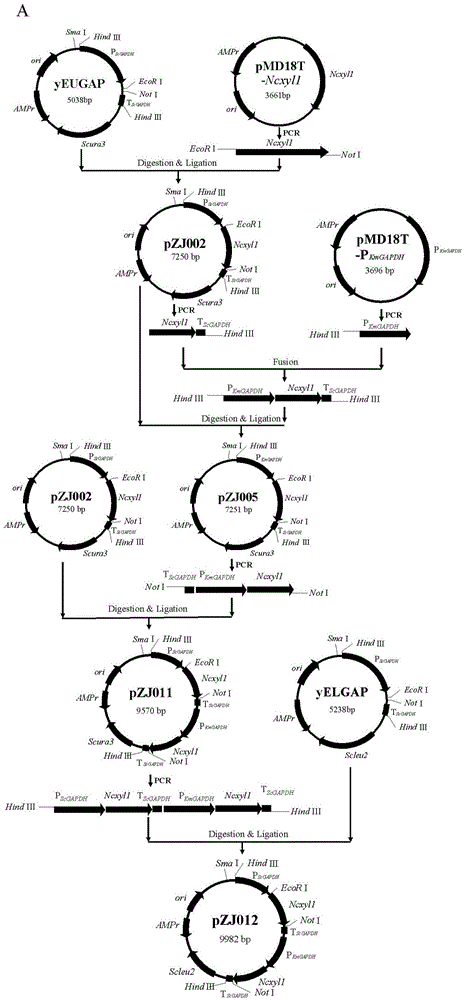

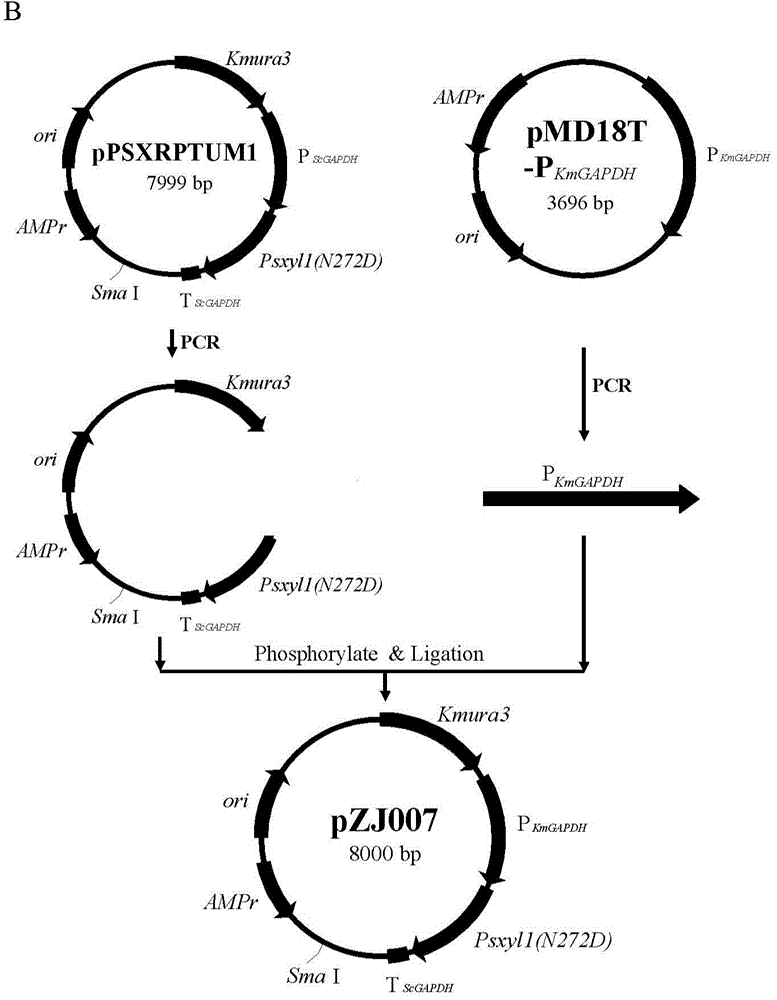

[0073] 1). Acquisition of NcXR gene (Woodyer et al., 2005):

[0074] The genome of Neurospora 74-OR23-1VA (purchased from Fungal Genetics Stock Center 2489, School of Biological Sciences, University of Missouri, Kansas City) was extracted, and the genome of Neurospora extracted was diluted 100 times as a template, and PrimeSTAR HS DNA was used polymerase (Dalian Baobiology) and NCXR-F1 (SEQ ID No.1), NCXR-R2 (SEQ ID No.4) primers for PCR, the product obtained is the NcXR gene (SEQ ID No. 21), and insert the gene into the pMD18-T vector (Dalian Bao Biology). Since the NcXR gene has introns, the T vector inserted into NcXR was used as a template, and PrimeSTAR HS DNA polymerase and NCXR-F1 (SEQ ID No.1), NCXR-R1 (SEQ ID No.2), NCXR- F2 (SEQ ID No.3), NCXR-R2 (SEQ ID No.4) primer PCR exon gene respectively, then fusion, obtain the exon gene fusion fragment of NcXR, clone again...

Embodiment 2

[0263] Example 2. Fermentation of strains containing different promoters and XR genes under synthetic medium

[0264] This example is used to compare the effect of different XR genes and different promoters on the production of xylitol. The results showed that the effect of NcXR gene on producing xylitol was better than that of PsXR, and the promoter P ScGAPDH and P KmGAPDH Little effect, but with P KmGAPDH The effect is slightly better.

[0265] 1. Recover strains on YPD medium plates. Control strains: YZB001, YLUA005. Experimental strains: YZJ001, YZJ003, YZJ005, YZJ006, YZJ007, YZJ008. Cultured at 37°C for 1 day.

[0266] 2. Pick out single clones respectively, and connect them to 5ml liquid YPD medium. 37°C, 250rpm, overnight.

[0267] 3. Prepare 39 bottles of 50ml xylose synthesis medium and distribute them in 250ml Erlenmeyer flasks. Formula: 50g / L xylose, 10g / L yeast extract, 20g / L bacteriological peptone, 10g / L glycerin. Sterilized and ready to use.

[0268] ...

Embodiment 3

[0275] Example 3. Fermentation of strains containing different copies of the NcXR gene at 42°C

[0276] This example is used to understand the comparison of the fermentation of strains containing different copies of the NcXR gene under high temperature (42° C.) conditions with the fermentation of strains containing one copy of the NcXR gene. The results prove that increasing the NcXR copy can make Increased fermentation capacity.

[0277] 1. Recover strains on YPD medium plates. Control strains: YZJ003, YZJ007. Experimental strains: YZJ012, YZJ014, YZJ015, YZJ017. Cultured at 37°C for 1 day.

[0278] 2. Pick out single clones respectively, and connect them to 5ml liquid YPD medium. 37°C, 250rpm, overnight.

[0279] 3. Prepare 27 bottles of 30ml xylose synthesis medium and pack them in 250ml Erlenmeyer flasks. Formula: 50g / L xylose, 10g / L yeast extract, 20g / L bacteriological peptone, 15g / L glycerin 50g / L xylose, 15g / L glycerin, 10g / L yeast extract, 20g / L bacteriological pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com