Manufacturing method for functionally gradient material capable of reinforcing tuyere

A technology of functionally graded materials and manufacturing methods, applied in the direction of tuyere, manufacturing tools, metal material coating process, etc., can solve the problems of inconvenient tuyere size forming, peeling, tuyere deformation, etc., and reduce thermal stress cracking or shedding. Trend, improve service life, and satisfy the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The invention adopts the surfacing welding+spraying technology to prepare the blast furnace copper matrix tuyere reinforcement layer, which can greatly improve the service life of the copper matrix tuyere. The annual consumption of blast furnace tuyere before the applicant adopts the present invention: 10*12 / 3=40 (pieces), and the annual consumption of blast furnace tuyere after adoption: 10*12 / 8=15 (pieces); annual average Consumption is reduced by almost 60%.

[0027] Concrete steps of the present invention are as follows:

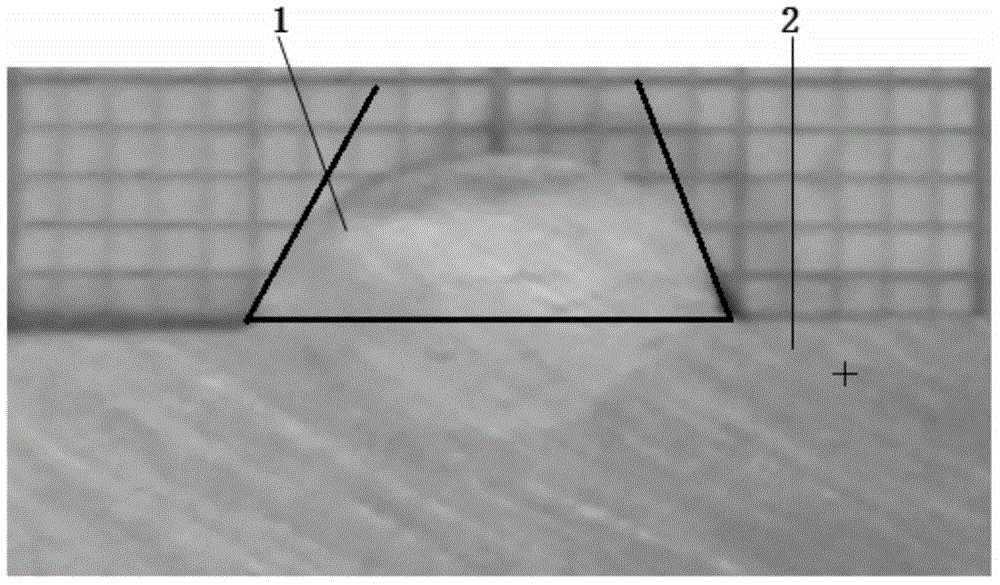

[0028] First, purify the reinforced surface of the copper matrix tuyere, and preheat to 500±50°C.

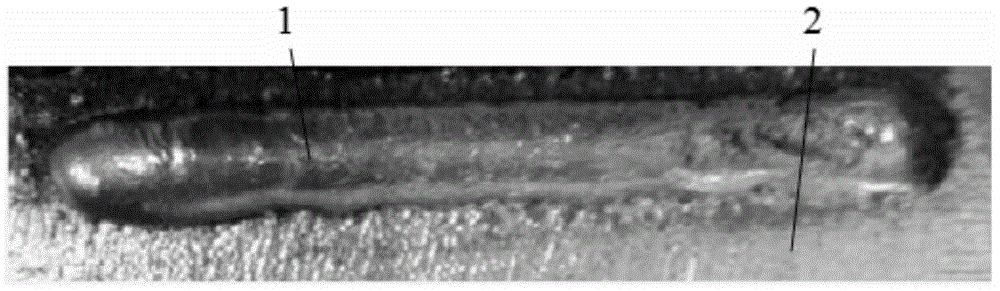

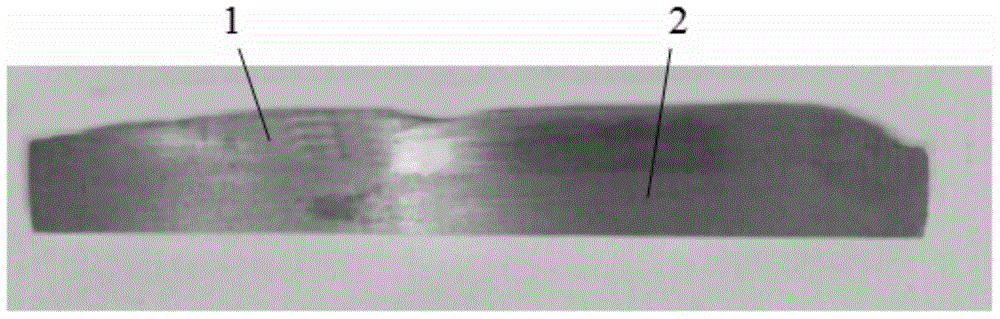

[0029] Surfacing a layer of nickel-copper alloy Ni202 on the tuyere 2 of the copper substrate as the transition layer 1 of the functionally graded material. The composition of the nickel-copper alloy Ni202 is C≤0.15, Mn≤4, Si≤1.5, Ni 62-69, Fe≤2.5, Ti≤1, Nb≤2.5, S≤0.015, P≤0.02, Al≤0.75, Cu balance.

[0030] Nickel-copper alloy material Ni202 (US...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com