Zymolytic oat milk product and preparation method of ultra-high pressure sterilization

A technology for ultra-high pressure sterilization and dairy products, which is applied in dairy products, milk preparations, applications, etc. It can solve the problems of high-viscosity colloids and easy protein precipitation, etc., and achieve the effects of improving quality factors, reducing operating procedures, and adding less

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

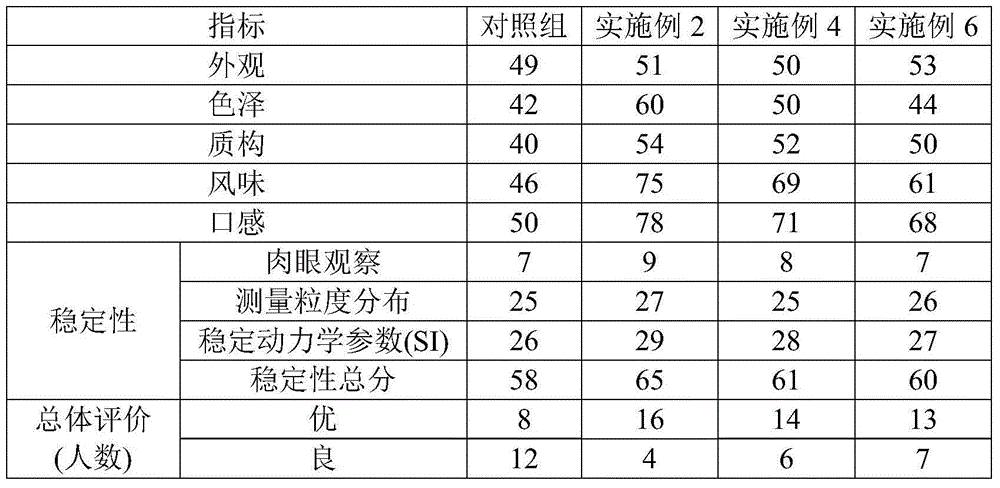

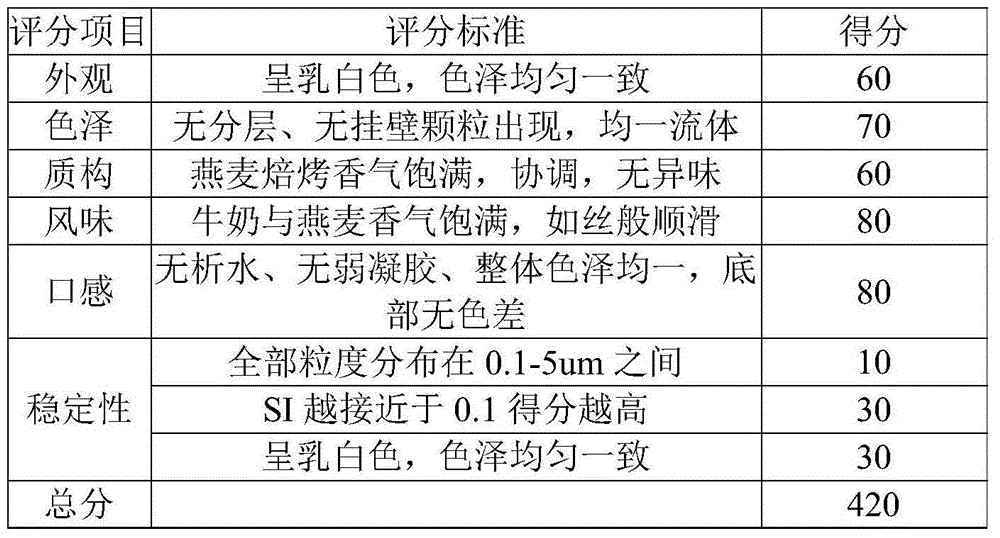

Examples

Embodiment 1

[0047] The raw material contains the following components: raw milk 80%, oat flour 3%, white sugar 5%, stabilizer 0.15% and water, the sum of the mass percentages of each component is 100%; the above percentages are mass percentages;

[0048] Wherein, the stabilizer is a compound stabilizer in which the mass ratio of mono-diglyceride fatty acid ester, sucrose fatty acid ester, gellan gum and xanthan gum is 8:5:2:3. The enzyme preparation is compounded with 0.09g of Amylex LT amylase (calculated at an added amount of 0.3g / 100g oat flour) and 0.18g of Diazyme P 25 glucoamylase (calculated at an added amount of 0.6g / 100g oat flour).

[0049] Described preparation method comprises the steps:

[0050] (1) After roasting the oatmeal at 180°C for 40 minutes, the raw materials are ground into powder through a low-temperature ultra-fine grinding process. During the grinding process, the temperature is controlled not to be higher than 10°C. The equipment used for grinding is non-metalli...

Embodiment 2

[0059] The raw material contains the following components: raw milk 65%, oat flour 4%, polydextrose 3.5%, stabilizer 0.18% and water, the sum of the mass percentages of each component is 100%; the above percentages are mass percentages;

[0060] Wherein, the stabilizer is a compound stabilizer in which the mass ratio of mono-diglyceride fatty acid ester, sucrose fatty acid ester, gellan gum and xanthan gum is 8:5:2:3. The enzyme preparation was compounded with 0.136g of Amylex LT amylase (calculated at an added amount of 0.34g / 100g oat flour) and 0.272g of Diazyme P 25 glucoamylase (calculated at an added amount of 0.68g / 100g oat flour).

[0061] Described preparation method comprises the steps:

[0062] (1) After roasting the oats at 200°C for 20 minutes, the raw materials are ground into powder through a low-temperature ultra-fine grinding process. During the grinding process, the temperature is controlled not to be higher than 10°C. The equipment used for grinding is non-me...

Embodiment 3

[0071] The raw material contains the following components: raw milk 60%, oat flour 6%, brown sugar 3%, stabilizer 0.25% and water, the sum of the mass percentages of each component is 100%; the above percentages are mass percentages;

[0072] Wherein, the stabilizer is a compound stabilizer in which the mass ratio of mono-diglyceride fatty acid ester, sucrose fatty acid ester, gellan gum and xanthan gum is 8:5:2:3. The enzyme preparation is compounded with 0.24 g of Amylex LT amylase (calculated at an added amount of 0.4 g / 100 g of oat flour) and 0.48 g of Diazyme P 25 glucoamylase (calculated at an added amount of 0.8 g / 100 g of oat flour).

[0073] Described preparation method comprises the steps:

[0074] (1) After roasting the oatmeal at 250°C for 10 minutes, the raw materials are ground into powder through a low-temperature ultra-fine grinding process. During the grinding process, the temperature is controlled not to be higher than 10°C. The equipment used for grinding is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com