Preparation and application of modified bletilla striata polysaccharide derivative nano-carrier

The technology of Bletilla striata polysaccharide and derivatives is applied in the field of preparation of hydrophobically modified low-molecular-weight Bletilla striata polysaccharide derivatives and nano-carriers thereof, and achieves the effects of prolonging action time, reducing toxic and side effects, and preventing enzymatic degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

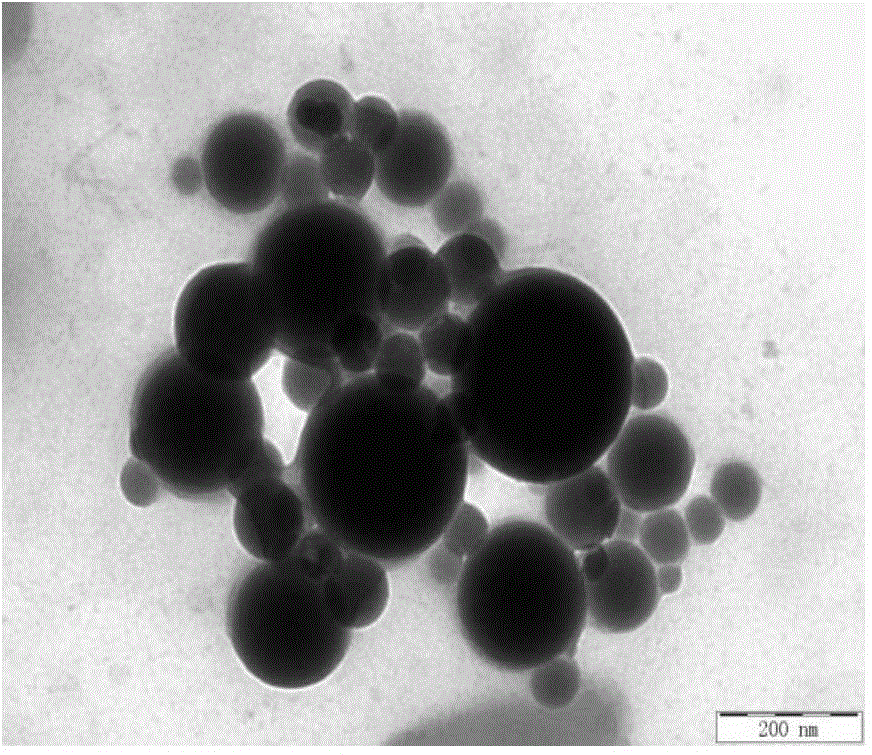

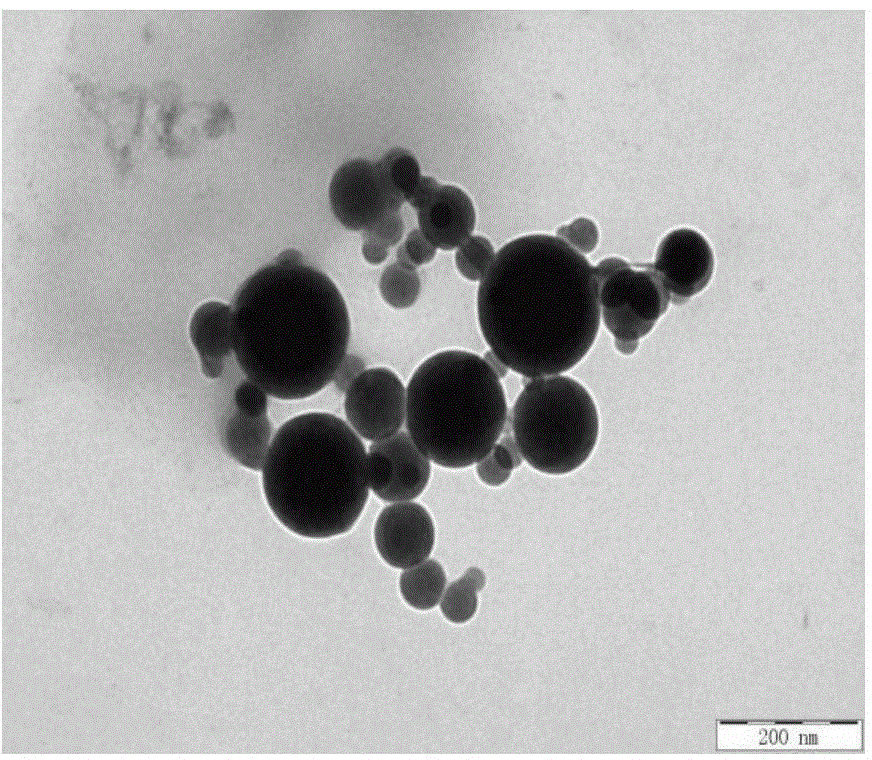

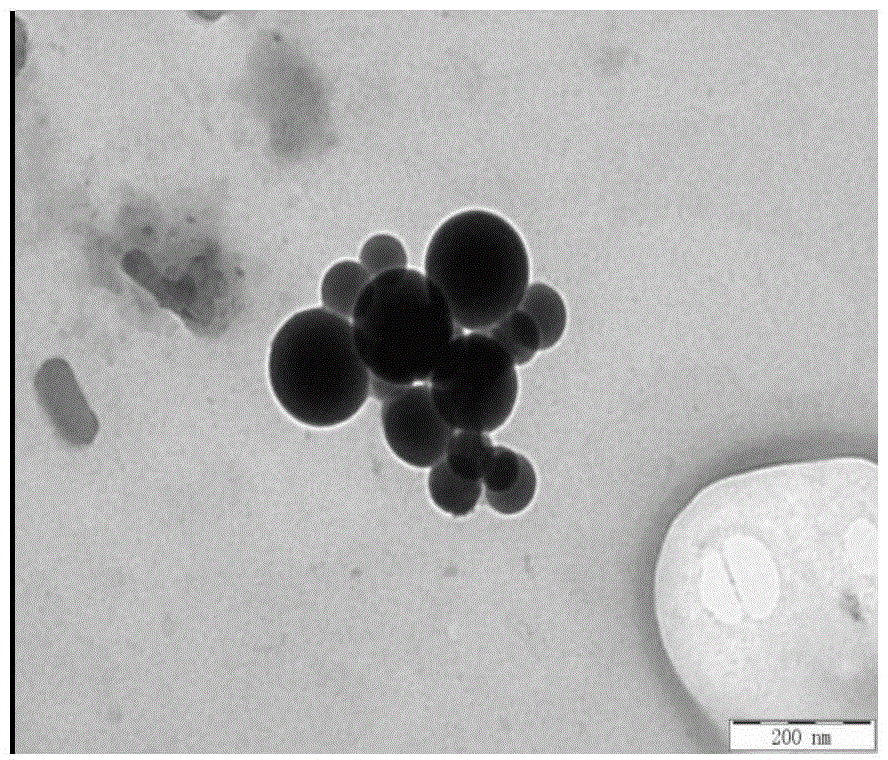

Image

Examples

example 1

[0031] Degradation and modification of Bletilla striata polysaccharide:

[0032] (1) Cellulase degradation of Bletilla striata polysaccharide

[0033] Accurately weigh 2.00g of Bletilla striata polysaccharide, disperse and dissolve in 100ml of distilled water, adjust the pH to 5.0 with potassium dihydrogen phosphate, add 0.45% (w / v) cellulase, incubate at 50°C for 4-6 hours, boil for 5-10 minutes Inactivate the enzyme; the reducing sugar content of the degradation product measured by the 3,5-dinitrosalicylic acid method is 14.27±0.59%, and the viscosity-average molecular weight is 4850.48Da.

[0034] (2) Synthesis of Bletilla striata polysaccharide grafted with deoxycholic acid

[0035] Accurately weigh 0.04g of the Bletilla striata polysaccharide after the enzymatic degradation of the above cellulose, dissolve it in 20mL dimethyl sulfoxide, and set aside; weigh 0.39g of deoxycholic acid, 0.19g of N,N-dicyclohexylcarbodiimide 1. Dissolve 0.12g of 4-dimethylaminopyridine in 5...

example 2

[0037] (1) Cellulase degradation of Bletilla striata polysaccharide

[0038] Accurately weigh 2.00g of Bletilla striata polysaccharide, disperse and dissolve it in 100ml of distilled water, adjust the pH to 4.0 with potassium dihydrogen phosphate, add 0.25% (w / v) cellulase, incubate at 40°C for 4-6 hours, boil for 5-10 minutes Inactivate the enzyme; the reducing sugar content of the degradation product measured by the 3,5-dinitrosalicylic acid method is 10.60±0.38%, and the viscosity-average molecular weight is 4235.21Da.

[0039] (2) Synthesis of Bletilla striata polysaccharide grafted with lauric acid

[0040]Accurately weigh 0.08g of Bletilla striata polysaccharide after cellulose enzymatic degradation, dissolve it in 40mLN,N dimethylformamide water (5:1, v / v) mixed solvent, set aside; weigh 0.16g lauric acid, 0.19g Dissolve N,N-dicyclohexylcarbodiimide and 0.31g 4-dimethylaminopyridine in 5mL of N,N dimethylformamide water (5:1, v / v) mixed solvent, activate in ice bath 2...

example 3

[0042] (1) Cellulase degradation of Bletilla striata polysaccharide

[0043] Accurately weigh 2.00g of Bletilla striata polysaccharide, disperse and dissolve it in 100ml of distilled water, adjust the pH to 4.5 with potassium dihydrogen phosphate, add 0.35% (w / v) cellulase, incubate at 45°C for 4-6 hours, boil for 5-10 minutes Inactivate the enzyme; the reducing sugar content of the degradation product measured by the 3,5-dinitrosalicylic acid method is 12.80±0.41%, and the viscosity-average molecular weight is 3164.39Da.

[0044] (2) Synthesis of Bletilla striata polysaccharide grafted with cholic acid

[0045] Accurately weigh 0.10g of Bletilla striata polysaccharide after enzymatic degradation, dissolve it in 25mL of methanol water (4:1, v / v) mixed solvent, and set aside; weigh 0.32g of cholic acid, 0.19g of N,N-bicyclohexyl Carbodiimide and 0.14g 4-dimethylaminopyridine were dissolved in 5mL of methanol water (4:1, v / v) mixed solvent, activated in ice bath for 2h, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| viscosity average molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com