Functional dressing for inhibiting scar hyperplasia and preparation method thereof

A functional scar technology, applied in the medical field, can solve problems such as single function and inability to meet complex wound care requirements, and achieve the effect of reducing pain and inhibiting scar hyperplasia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

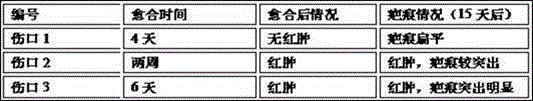

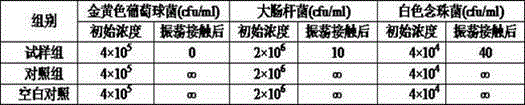

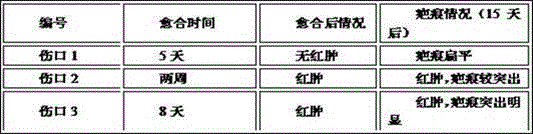

Examples

Embodiment 1

[0021] Add 10g of chitosan and 20g of fucoidan to a mortar and grind them in a certain proportion, and stir them mechanically for 3 minutes to form a powder mixture; add the above powder mixture to 50mL of methyl silicone oil with a molecular weight of about 8000, and add 20g polyvinyl alcohol and carboxymethyl cellulose of equal mass form a mixed solution; add 0.1g sodium dodecylbenzene sulfonate to the above mixed solution, and stir it with a mechanical stirrer at a high speed at 40°C to make it evenly mixed to obtain a composite silicon gel Glue; the composite silicone gel is cast into a film, soaked in 75% alcohol disinfectant after the film is formed, washed with distilled water at the same time, and then drilled on the surface of the film with a needle with a diameter of 0.5mm. 2 small holes; the activated carbon fiber is pasted on one side of the composite silicone gel and fixed on the pressure-sensitive non-woven fabric at the same time, and the other side is covered wi...

Embodiment 2

[0029] Add 15g of chitosan and 30g of fucoidan into a mortar and grind them in a certain proportion, and stir them mechanically for 5 minutes to form a powder mixture; add the above powder mixture to 45mL of methyl vinyl cyclosiloxane with a molecular weight of about 15,000 and add 10g carboxyethyl cellulose to form a mixed solution; add 0.05g hexadecyltrimethylammonium bromide to the above mixed solution, and stir it with a mechanical stirrer at a high speed at 60°C to make it evenly mixed to obtain a composite silicon gel Glue; the composite silicone gel is cast into a film, soaked in 75% alcohol disinfectant after the film is formed, washed with distilled water at the same time, and then drilled on the surface of the film with a needle with a diameter of 0.9mm to penetrate 150pin / cm 2 small holes; the activated carbon fiber is pasted on one side of the composite silicone gel, and fixed on the pressure-sensitive adhesive non-woven fabric at the same time, and the other side i...

Embodiment 3

[0037] Put 8g of chitosan and 16g of fucoidan in a certain proportion and grind them in a mortar, stir them mechanically for 1min to form a powder mixture; add the above powder mixture to 60mL of phenyl silicone oil with a molecular weight of about 20000, and add 16g Carboxymethyl cellulose forms a mixed solution; add 0.08g Tween-80 to the above mixed solution, stir it with a mechanical stirrer at a high speed at 50°C to mix evenly, and obtain a composite silicone gel; cast the composite silicone gel into a film After the film is formed, soak it in 75% alcohol disinfectant, wash it with distilled water, and then use a needle with a diameter of 0.7mm to drill a penetrating 200pin / cm on the surface of the film. 2 small holes; the activated carbon fiber is pasted on one side of the composite silicone gel, and fixed on the pressure-sensitive adhesive non-woven fabric at the same time, and the other side is covered with a peeling layer, and the product is obtained after packaging and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com