Rosin for brazing flux and brazing flux using the same

A technology of flux and rosin, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problem that the use of methyl dehydroabietic acid is not known, and achieve excellent washability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

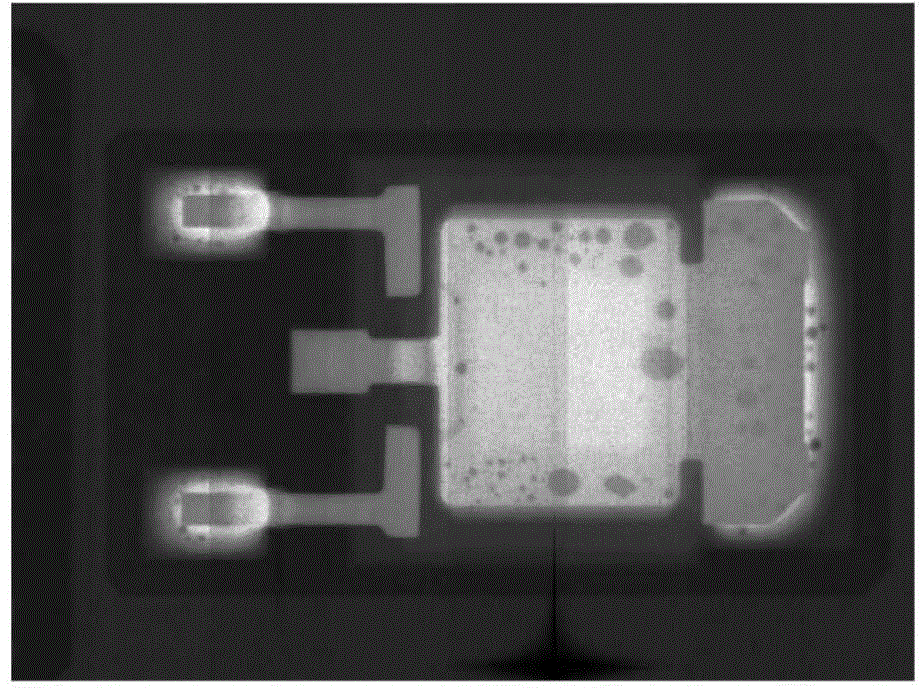

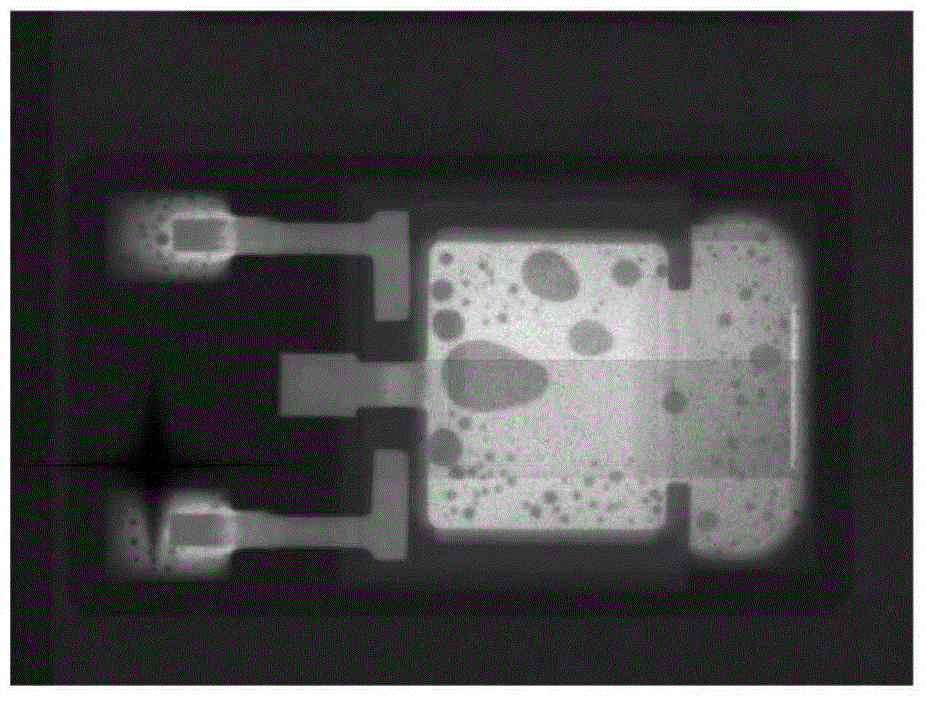

Image

Examples

Embodiment 1

[0066] In a four-necked flask equipped with a stirrer, a thermometer, a cooler, a drain pipe, and a nitrogen inlet pipe, add 1000 g of Chinese-made gum rosin (acid value: 165, softening point: 87 ° C, Garner chroma: 7), in a nitrogen atmosphere It was melted at 150°C. Next, while stirring, 0.5 g of p-toluenesulfonic acid was added, and 109 g of paraformaldehyde (concentration: 92% by mass) was added little by little over 2 hours. The paraformaldehyde used was 1.1 mol with respect to 1 mol of rosin. After addition, it heated up to 180 degreeC, and it was made to react for 4 hours, and 1021 g of rosins for soldering fluxes (acid value: 150, softening point: 90 degreeC, Garner chromaticity: 12) were obtained.

[0067] The obtained soldering flux rosin was subjected to GPC analysis and GC-MS analysis. GPC analysis and GC-MS analysis were performed using the equipment described below.

[0068] (GPC analysis)

[0069] Equipment: manufactured by Shodex, GPC101

[0070] Column: m...

Embodiment 2

[0077]Under a nitrogen atmosphere, 700 g of rosin for brazing flux obtained in Example 1 was subjected to vacuum distillation (1 torr), and the main fraction (406 g, acid value: 168, softening point: 84° C., Garner chromaticity :6). As a result of GPC analysis, no nonvolatile dehydration condensate was detected from the recovered main fraction (rosin for soldering flux). Furthermore, GC-MS analysis was performed on the main fraction for qualitative and quantitative analysis. The obtained rosin for soldering flux contained 57% by mass of methyl dehydroabietic acid and 43% by mass of other resin acids. Other resin acids are resin acids derived from Chinese gum rosin as a raw material, such as abietic acid, dehydroabietic acid, and pimaric acid, and resin acids produced by isomerization during the reaction.

Embodiment 3

[0079] 200 g of the rosin for brazing flux obtained in Example 2 was put into an induction stirring autoclave and melted. Next, 2 g of 5 mass % palladium carbon (water content 50%) was added to remove oxygen in the reaction system. Next, hydrogen gas was introduced into the reaction system to pressurize it to 10 MPa, and the temperature was raised to 250° C. while stirring to perform a hydrogenation reaction for 4 hours. After the reaction, the reaction mixture was filtered under pressure to remove the catalyst to obtain rosin for soldering flux (191 g, acid value: 167, softening point: 82° C., Harden color value: 220). The rosin for soldering fluxes is almost colorless, so the Garner color scale was not used but the Harden color value was used. The obtained rosin for soldering flux was subjected to GC-MS analysis for qualitative and quantitative analysis. The obtained rosin for soldering flux contained 55% by mass of methyl dehydroabietic acid and 45% by mass of other resin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com