Method for preparing bi12tio20 nanometer powder by microwave-assisted sol-gel method

A sol-gel method, nano-powder technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as unreported, low purity, complex process, etc., and achieve wide application prospects and process time. Short, small powder particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

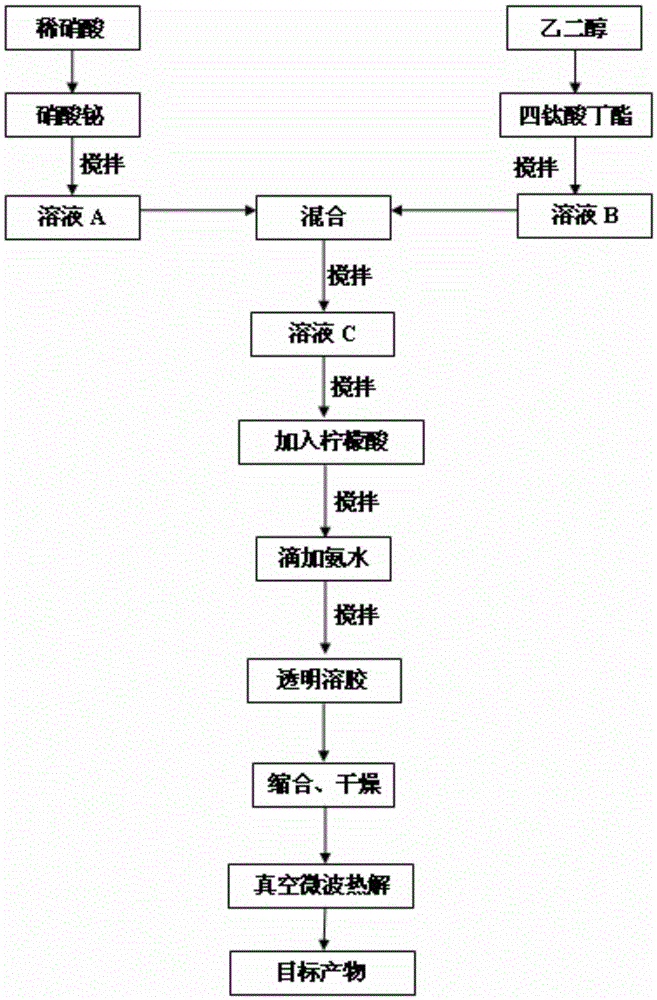

Method used

Image

Examples

Embodiment 1

[0029] Will 11.64gBi (NO 3 ) 3 ·5H 2 O was added to 20ml of 1.0mol / LHNO 3solution, and stirred until completely dissolved to obtain solution A; 0.68g (CH 3 (CH 2 ) 3 O) 4 Ti was added to 10ml of ethylene glycol, and stirred until completely mixed to obtain solution B; under the condition of stirring, the A solution and the B solution were completely mixed to obtain a clear solution C; 2.5g of citric acid, and stirred until the solution was completely mixed uniformly; under the condition of continuing to stir, dropwise added mass concentration of 28% ammonia water to adjust the pH value of the solution to 8, and obtained a transparent sol; the obtained transparent sol was condensed at 110°C, Dry for 40 hours to obtain a xerogel; under low vacuum conditions (absolute pressure 0.02MPa), heat the obtained xerogel to 600°C by microwave, and heat it for 10 minutes, then thermally decompose it to obtain light yellow Bi 12 TiO 20 Powder.

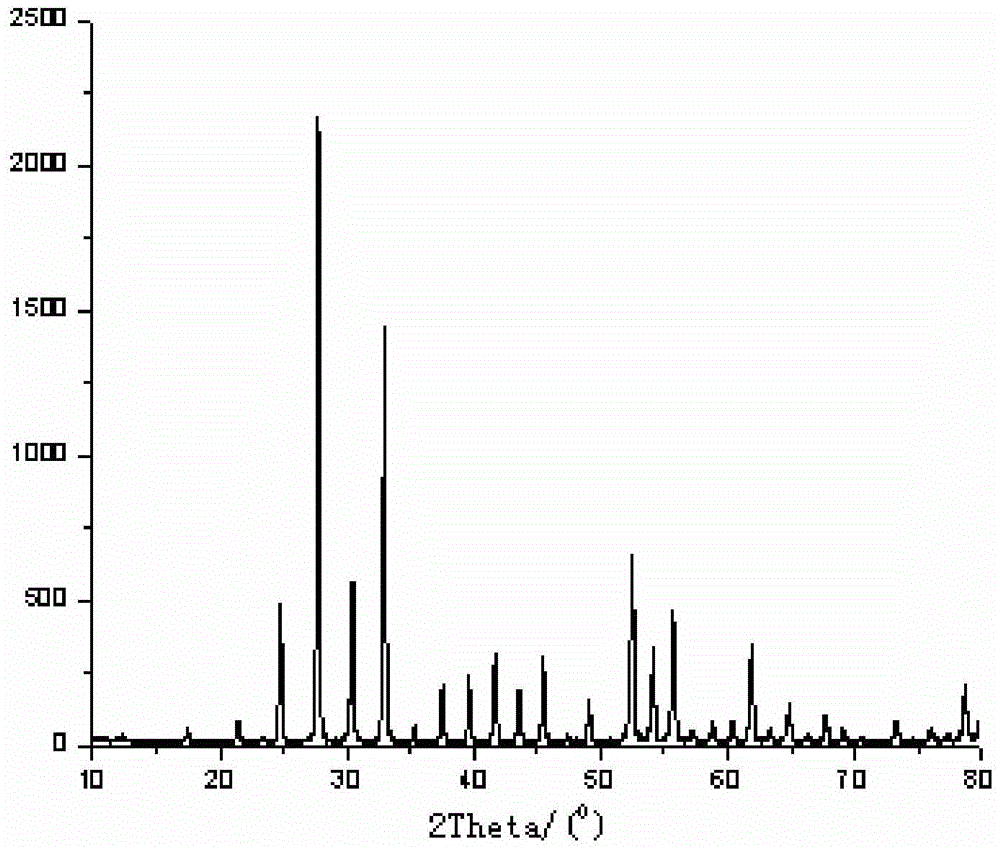

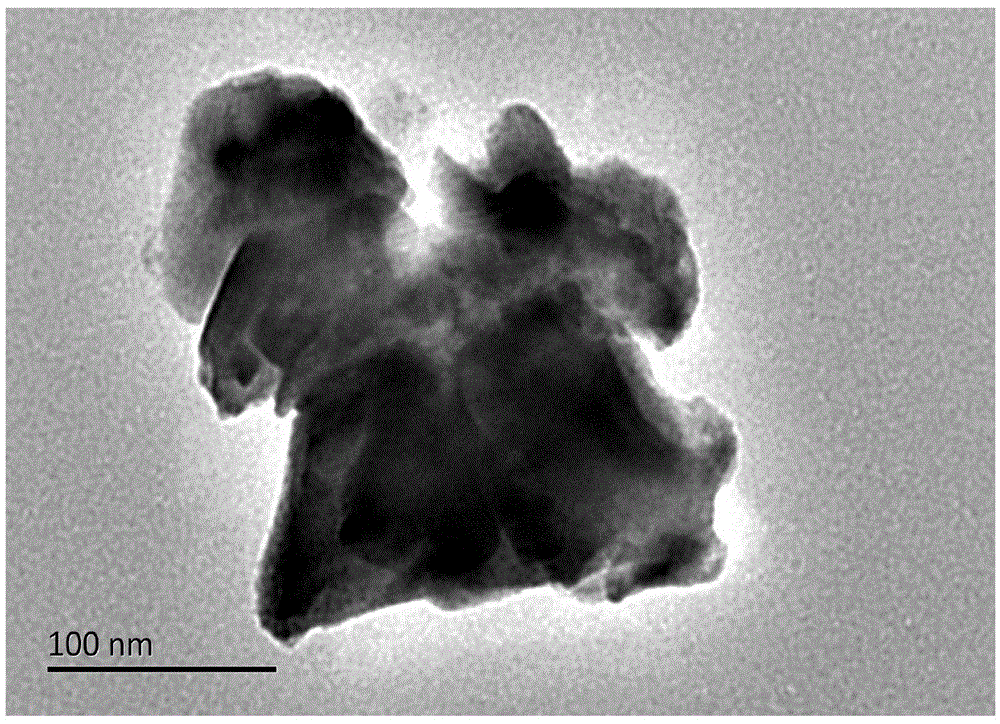

[0030] By XRD analysis (attached fi...

Embodiment 2

[0032] Will 11.64gBi (NO 3 ) 3 ·5H 2 O was added to 20ml of 1.0mol / LHNO 3 solution, and stirred until completely dissolved to obtain solution A; 0.68g (CH 3 (CH 2 ) 3 O) 4 Ti was added to 10ml of ethylene glycol, and stirred until completely mixed to obtain solution B; under the condition of stirring, the A solution and the B solution were completely mixed to obtain a clear solution C; 2.5g of citric acid, and stirred until the solution was completely mixed uniformly; under the condition of continuous stirring, the pH value of the solution was adjusted by dropping 25% mass concentration of ammonia water to obtain a transparent sol; the obtained transparent sol was condensed at a temperature of 100°C, Dry for 60 hours to obtain a dry gel; under low vacuum conditions (absolute pressure 0.01MPa), heat the obtained dry gel to 640°C by microwave, and keep it warm for 10 minutes. The main component of the obtained product is Bi 12 TiO 20 , there exists Bi 2 o 3 impurity ph...

Embodiment 3

[0034] Will 11.64gBi (NO 3 ) 3 ·5H 2 O was added to 20ml of 1.0mol / LHNO 3 solution, and stirred until completely dissolved to obtain solution A; 0.68g (CH 3 (CH 2 ) 3 O) 4 Ti was added to 10ml of ethylene glycol, and stirred until completely mixed to obtain solution B; under the condition of stirring, the A solution and the B solution were completely mixed to obtain a clear solution C; 2.5g of citric acid, and stirred until the solution was completely mixed uniformly; under the condition of continuous stirring, dropwise added mass concentration of 26% ammonia water to adjust the pH value of the solution to 8, and obtained a transparent sol; the obtained transparent sol was condensed at 115°C, Dry for 36 hours to obtain a dry gel; under low vacuum conditions (absolute pressure 0.013MPa), heat the obtained dry gel to 560°C by microwave and keep it warm for 10 minutes. The main component of the obtained product is Bi 12 TiO 20 , there exists Bi 4 Ti 3 o 12 and Bi 2 o ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com