A kind of preparation method of nanoscale tinb2o7 with porous structure

A porous structure, nano-scale technology, applied in the field of electrochemical material preparation and energy, can solve the problems of unsatisfactory electrochemical performance, low utilization rate of reaction furnace, large product size, etc., to enhance the capacity of high-current charge and discharge, and easy to expand Large-scale production, the effect of small particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] At room temperature, weigh 0.54g of niobium pentachloride and dissolve it in 3mL of dimethylformamide. After the niobium salt is completely dissolved, weigh 0.2842g of titanium isopropoxide and dissolve it in the above solution (wherein titanium and niobium The molar ratio is 1:2), disperse and mix with 40KHz ultrasound for 0.5h, pour the completely dispersed mixed solution into a corundum porcelain boat, and place it directly in a tube furnace for calcination. The atmosphere in the furnace is air. The target temperature is 800°C, and the heating rate is 3°C min -1 , the holding time is 3h, and the nano-scale TiNb with pure phase porous structure is obtained 2 o 7 .

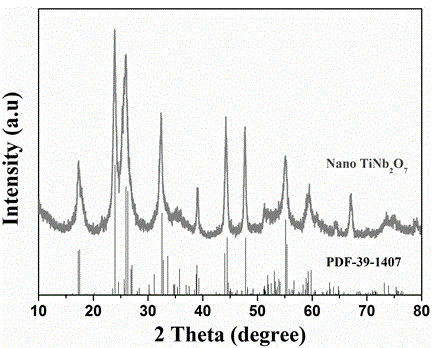

[0026] in, figure 1Obtain porous structure nanoscale TiNb for embodiment respectively 2 o 7 XRD pattern of the material.

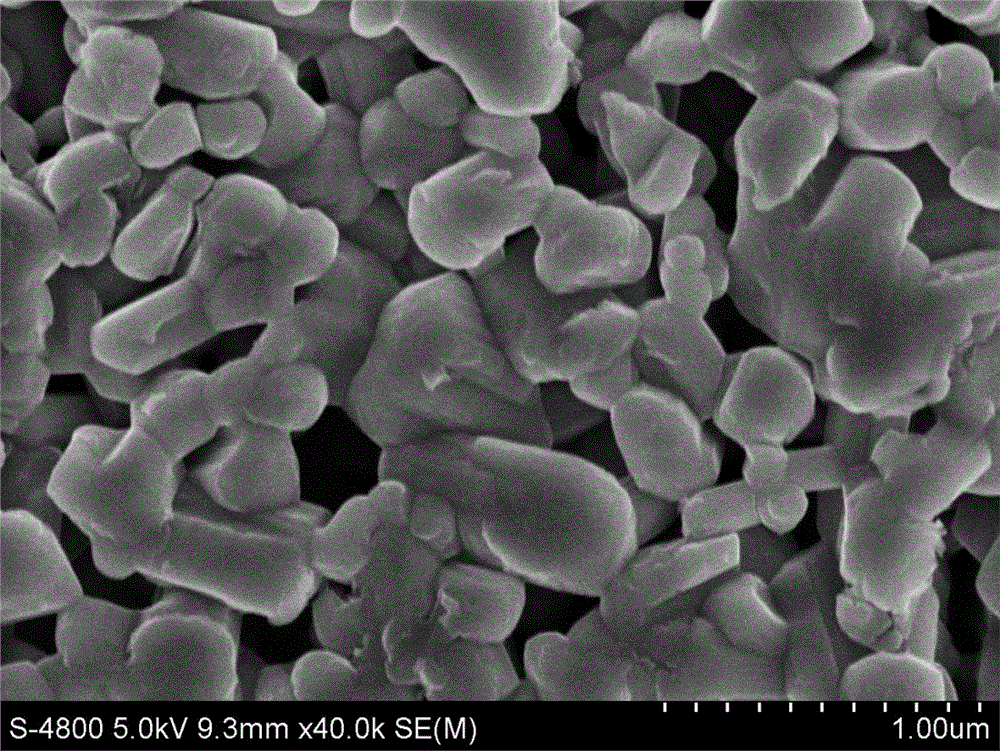

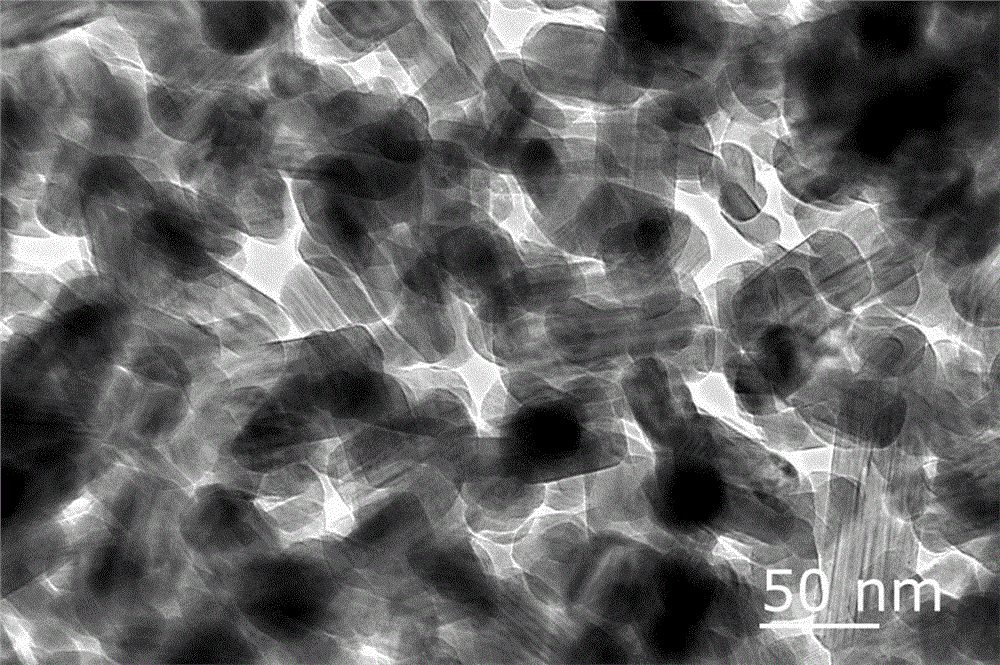

[0027] figure 2 , image 3 Respectively the porous structure nanoscale TiNb that embodiment obtains 2 o 7 SEM and TEM images.

[0028] Figure 4 Porous structure nanoscale...

Embodiment 2

[0032] At room temperature, weigh 0.54g of niobium pentachloride and dissolve it in 3mL of dimethylformamide. After the niobium salt is completely dissolved, weigh 0.2842g of titanium isopropoxide and dissolve it in the above solution (titanium and niobium in the solution The molar ratio is 1:2), 40KHz ultrasonic dispersion for 0.5h, pour the completely dispersed mixed solution into a corundum porcelain boat, and place it directly in a tube furnace for calcination. The atmosphere in the furnace is air, and the target temperature is 800 ℃, heating rate 3℃min -1 , the holding time is 6h, and the nano-scale TiNb with pure phase porous structure is obtained 2 o 7 .

Embodiment 3

[0034] At room temperature, weigh 0.54g of niobium pentachloride and dissolve it in 3mL of dimethyl sulfoxide. After the niobium salt is completely dissolved, weigh 0.2842g of titanium isopropoxide and dissolve it in the above solution (the moles of titanium and niobium The ratio is 1:2), 40KHz ultrasonic dispersion for 0.5h, pour the completely dispersed mixed solution into a corundum porcelain boat, and place it directly in a tube furnace for calcination. The atmosphere in the furnace is air, and the target temperature is 800°C. Heating rate 3°C min -1 , the holding time is 9h, and the nano-scale TiNb with pure phase porous structure is obtained 2 o 7 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com