Tirofiban hydrochloride preparation process

A technology for tirofiban and hydrochloric acid, which is applied in the field of preparation technology for preparing tirofiban hydrochloride, can solve the problems of unfavorable industrial production and low yield, and achieve the effects of mild reaction conditions and high total yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

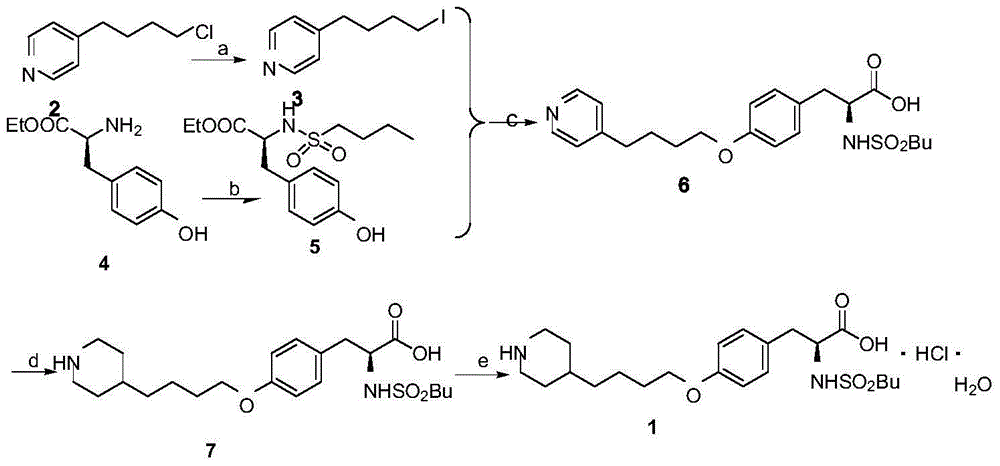

Method used

Image

Examples

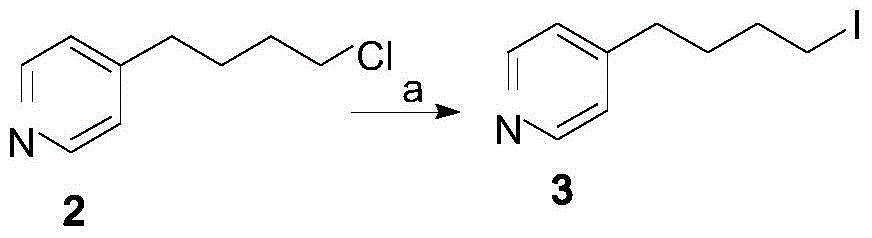

Embodiment example 1

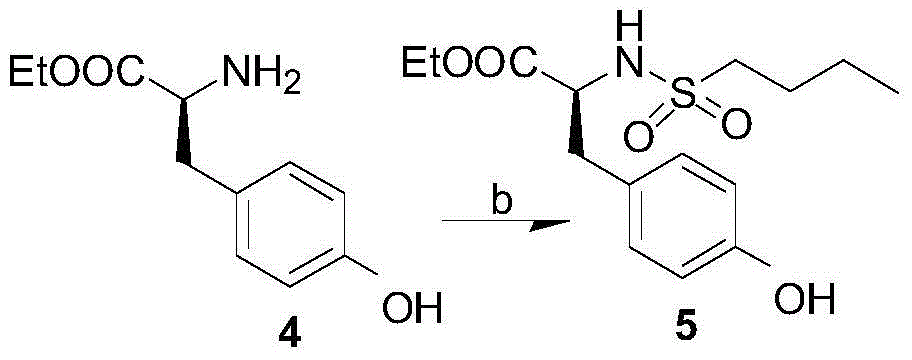

[0020] Preparation of N-butylsulfonyl-L-tyrosine ethyl ester 5

[0021] Compound 4 (450.5 g, 2.2 mol) was dissolved in 3 liters of ethyl acetate, sodium bicarbonate (1.1 kg, 13.1 mol) and n-butylsulfonyl chloride (407 g, 2.6 mol) were added, heated to 40°C and stirred for 5 hours After filtering, the filtrate was washed successively with 1.0 mol / L dilute hydrochloric acid (750 ml), saturated brine (750 ml), and water (750 ml*2), dried over anhydrous sodium sulfate and filtered, the filtrate was concentrated, and the residue was weighed with toluene Crystallized to obtain off-white solid powder 5 (581.0 g, yield 82.0%).

[0022] Preparation of N-(butanesulfonyl)-O-(4-pyridylbutyl)-L-tyrosine 6

[0023] Compound 2 (620.0 g, 4.0 mol) was added to 5.6 liters of dimethyl sulfoxide, followed by sodium iodide (7.5 g, 0.05 mol), and after stirring vigorously at room temperature for 4 hours, compound 5 (1.18 kg, 3.6 mol) was added , add potassium hydroxide aqueous solution (4 mol / L, ...

Embodiment example 2

[0028] Preparation of N-butylsulfonyl-L-tyrosine ethyl ester 5

[0029] Compound 4 (450.5 g, 2.2 mol) was dissolved in 3 liters of ethyl acetate, potassium carbonate (1.8 kg, 13.1 mol) and n-butylsulfonyl chloride (407 g, 2.6 mol) were added, heated to 40°C and stirred for 5 hours Filter, wash the filtrate with 1.0 mol / L dilute hydrochloric acid (750 ml), saturated brine (750 ml), and water (750 ml*2) successively, dry over anhydrous sodium sulfate and filter, concentrate the filtrate, and recrystallize the residue from toluene , to obtain off-white solid powder 5 (583.1 g, yield 82.3%).

[0030] Preparation of N-(butanesulfonyl)-O-(4-pyridylbutyl)-L-tyrosine 6

[0031] Compound 2 (620.0 g, 4.0 mol) was added to 5.6 liters of dimethyl sulfoxide, followed by sodium iodide (7.5 g, 0.05 mol), and after stirring vigorously at room temperature for 4 hours, compound 5 (1.18 kg, 3.6 mol) was added , add sodium carbonate aqueous solution (5 mol / L, 3.0 L) dropwise under stirring, hea...

Embodiment example 3

[0036] Preparation of N-butylsulfonyl-L-tyrosine ethyl ester 5

[0037]Compound 4 (450.5 g, 2.2 mol) was dissolved in 3 liters of acetone, sodium bicarbonate (1.1 kg, 13.1 mol) and n-butylsulfonyl chloride (407 g, 2.6 mol) were added, heated to 40°C and stirred for 5 hours, then filtered , the filtrate was washed successively with 1.0 mol / L dilute hydrochloric acid (750 ml), saturated brine (750 ml), and water (750 ml*2), dried over anhydrous sodium sulfate and filtered, the filtrate was concentrated, and the residue was recrystallized from toluene. The off-white solid powder 5 (577.0 g, yield 81.4%) was obtained.

[0038] Preparation of N-(butanesulfonyl)-O-(4-pyridylbutyl)-L-tyrosine 6

[0039] Compound 2 (620.0 g, 4.0 mol) was added to 5.6 liters of N,N-dimethylimide, followed by sodium iodide (7.5 g, 0.05 mol), and after stirring vigorously at room temperature for 4 hours, compound 5 (1.18 kg , 3.6 mol), stirring potassium hydroxide aqueous solution (4 mol / liter, 2,2 l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com