Ni(II) metal-organic frameworks and their synthesis methods and applications

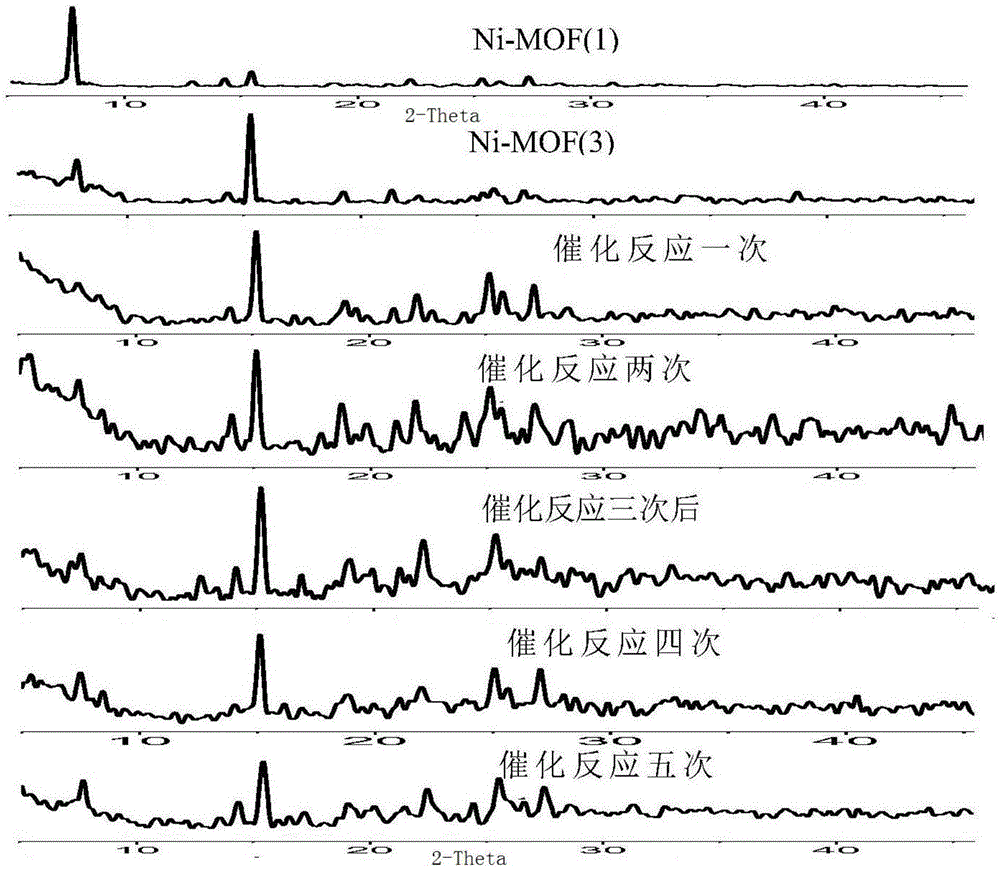

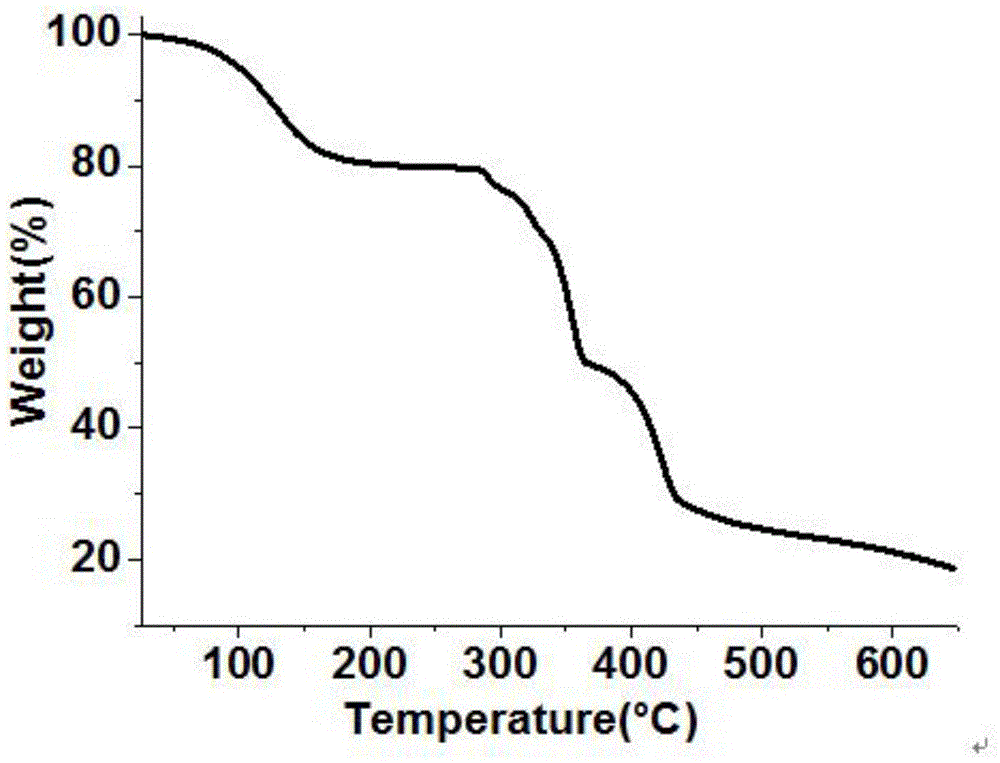

A metal-organic framework, ni-mof-3 technology, used in nickel-organic compounds, organic chemistry, organic compounds/hydrides/coordination complex catalysts, etc., which can solve the problems of long running time, strong toxicity, and low catalytic efficiency question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

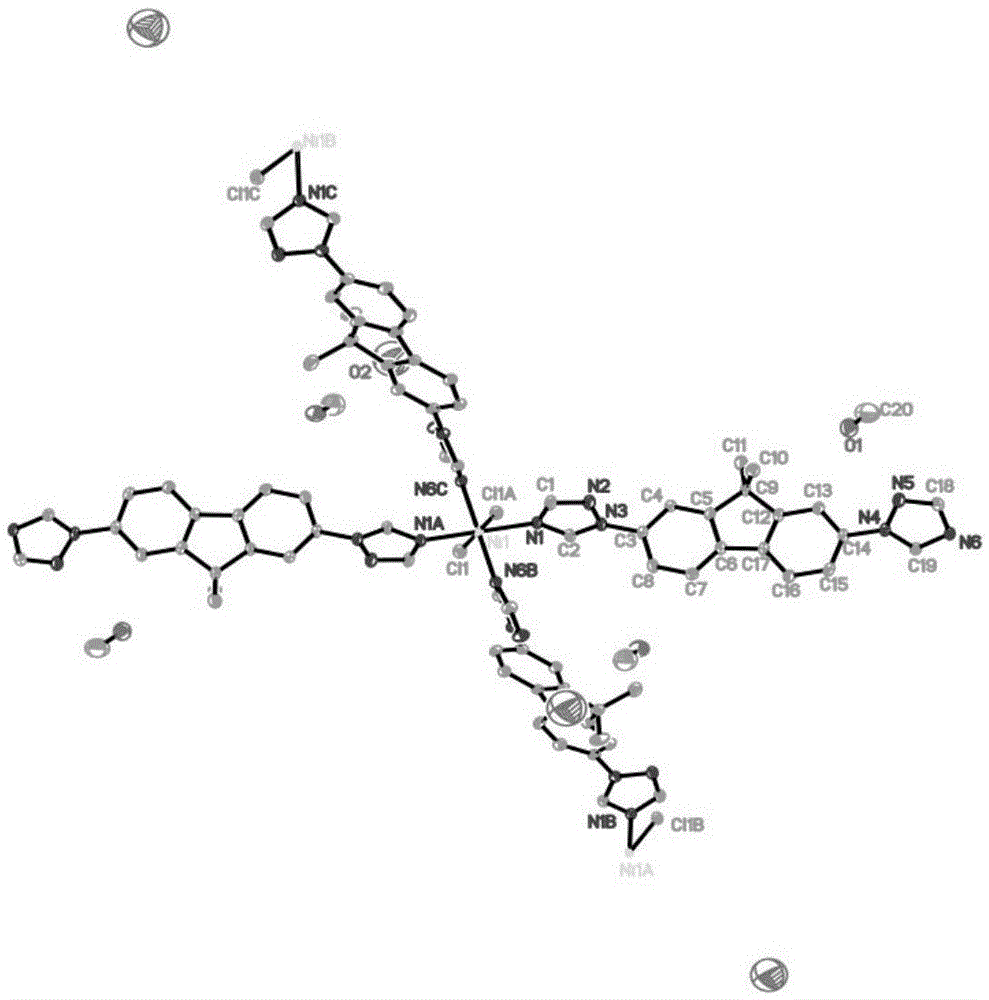

[0064] The synthesis route of the catalyst synthesized by the present invention is as follows:

[0065] 1. Preparation of Ligand L:

[0066]

[0067] At room temperature, 2,7-dibromofluorene (10.40g, 32mmol), tetrabutylammonium bromide (0.10g, 0.3mmol), methyl iodide (9.93g, 90mmol), and 10mL of 50% NaOH solution were added to 140mL of In DMSO, ultrasonic reaction (100W) was performed for 5 hours. After the reaction was completed, it was poured into 500mL water, stirred for 20min and left to stand for 1 hour, filtered with suction, and the filter cake was washed with 1% NaCl aqueous solution and dried to obtain 10.97g of a yellow solid. The yield was 97.40%.

[0068] N 2 Under protection, intermediate A (3.52g, 10mmol) 1,2,4-triazole (1,93g, 28mmol), cesium carbonate (13.03g, 40mmmol, cuprous iodide (0.762g, 4mmol) were placed in 100ml In the there-necked flask, 20mlDMF was used as solvent, heated to 120°C, tracked by TLC, poured into 300ml of water after the reaction ...

experiment example 1

[0076] Experimental Example 1 Benzaldehyde reacts with trimethylsilyl cyanide to generate 2-phenyl-2-(trimethylsilyloxy) acetonitrile

[0077] At room temperature, benzaldehyde (106mg, 1mmol) and trimethylsilyl cyanide (119mg, 1.2mmol) were added to a 25ml round bottom flask, and then 32.5mg (0.033mmol) of the catalyst Ni-MOF-3 was added, and the reaction was stirred. 1 After the HNMR tracking reaction, 1.5 ml of dichloromethane was added, and the catalyst was recovered by quick centrifugation, and the liquid was used to calculate the yield by GC-MS.

[0078] Purification of the product (2-phenyl-2-(trimethylsilyloxy)acetonitrile): evaporate the centrifuged liquid to dryness under reduced pressure, dissolve it in n-hexane, perform silica gel column chromatography (n-hexane:ethyl acetate=9:1 ) to obtain a colorless oily product. That 1 HNMR such as Figure 14 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com