Grafted polysilane compound, preparation method and application of grafted polysilane compound in battery electrolyte

A technology of polysilane and compound, which is applied in the application field of grafted polysilane compounds and battery electrolyte, can solve the problems of adverse effects on the performance of electrolyte at low temperature, difficult synthesis process, high cost of electrolyte, etc. Discharge cycle stability, good solubility, and easy preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

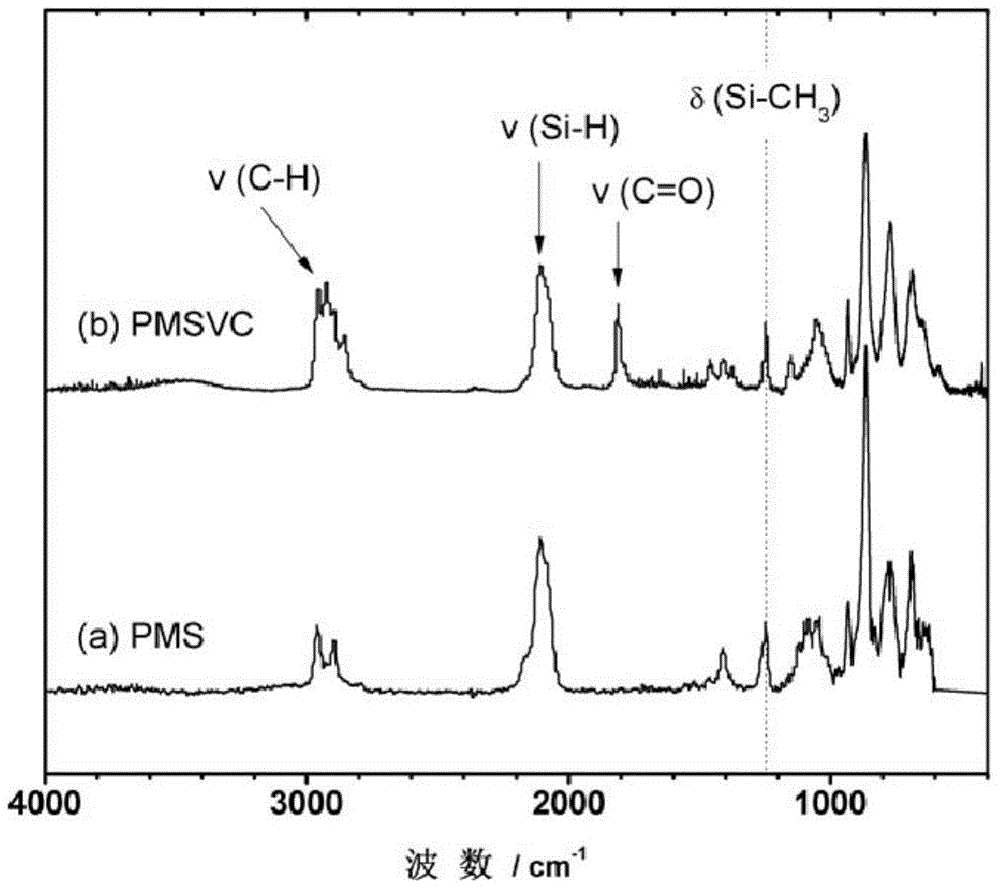

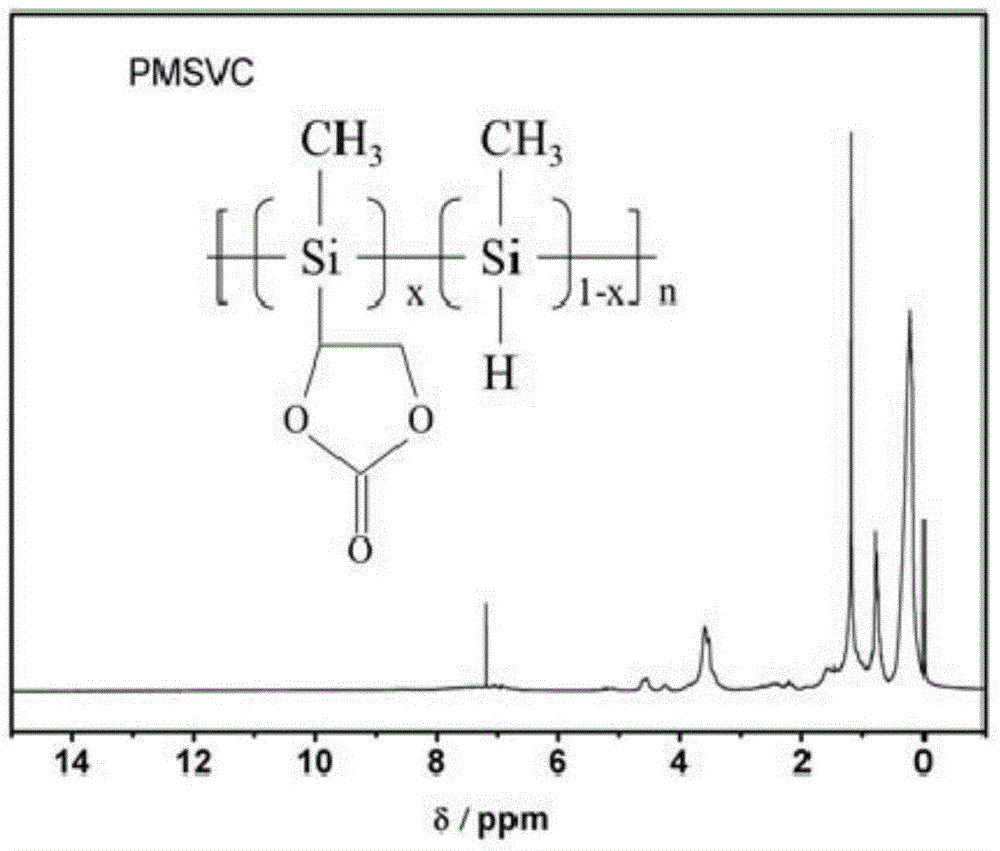

[0048] A kind of graft polysilane compound PMSVC, its structural formula is as follows:

[0049]

[0050] Among them, the degree of polymerization n is 21; on the grafted group -CH 2 - the number m of chain links is 0; the graft substitution rate x is 8%.

[0051] The synthetic method of grafted polysilane compound PMSVC specifically comprises the following steps:

[0052] (1) Take 0.88g vinylene carbonate (VC) and 4.40g polyhydromethylsilane (PMS) (mass ratio of VC and PMS is 1:10~2:1 can be implemented), dissolve in tetrahydrofuran (THF) Add 0.01g of azobisisobutyronitrile (AIBN), reflux at 60-70°C for 12h, and distill off the solvent under reduced pressure to obtain the grafted polysilane compound PMSVC.

[0053] (2) The grafted polysilane compound PMSVC was added into n-hexane under the protection of Ar atmosphere, and stirred to fully dissolve the reaction product to obtain a mixed solution. An equal amount of methanol was added to the mixture for sedimentation, and...

Embodiment 2

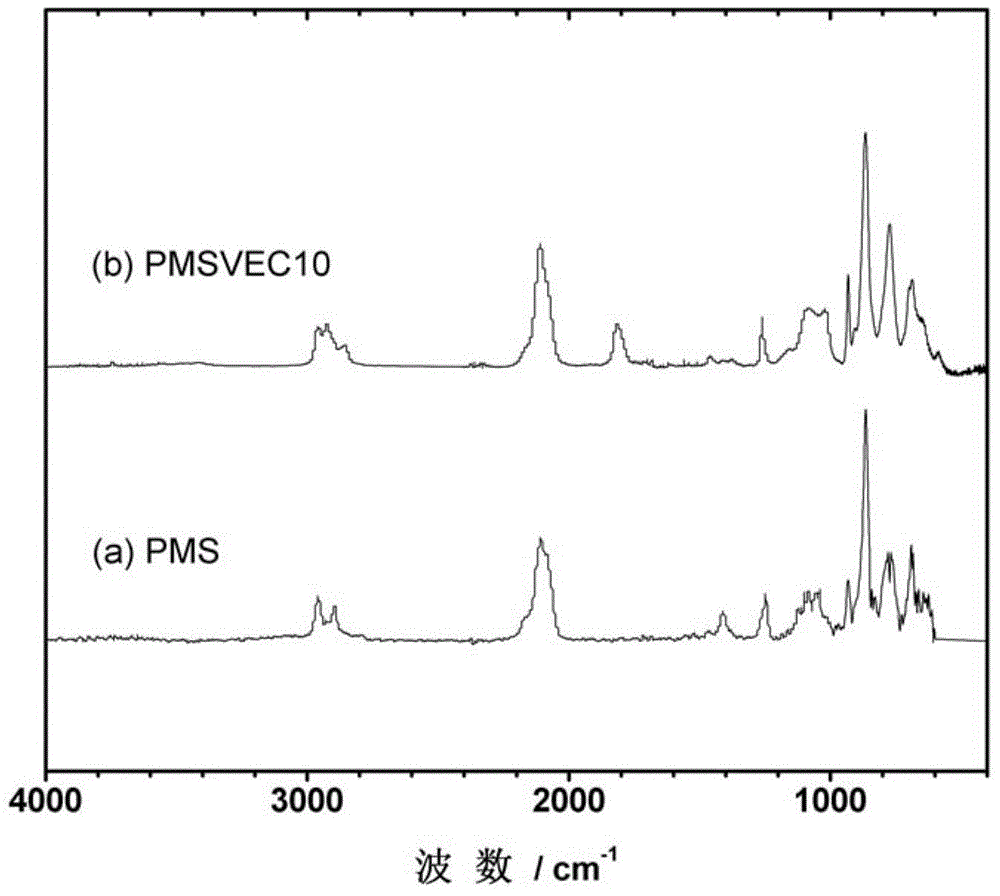

[0061] A kind of graft polysilane compound PMSVEC10, its structural formula is as follows:

[0062]

[0063] Wherein, the degree of polymerization n is 20; -CH 2 -The number m of chain links is 2; the graft substitution rate x is 0.10.

[0064] The synthetic method of graft polysilane compound PMSVEC10 specifically comprises the following steps:

[0065] (1) Take 1.14g ethylene carbonate (VEC) and 4.40g PMS (the mass ratio of VEC and PMS is 1:10~2.5:1, all can be implemented), dissolve in THF, add 0.01g AIBN, at 60 Reflux at ~70°C for 12h, and distill off the solvent under reduced pressure.

[0066] (2) Add n-hexane under the protection of Ar atmosphere, stir to make it fully dissolved. An equal amount of methanol was added for sedimentation, and the supernatant was discarded after centrifugation to obtain a precipitate.

[0067] (3) Add 20mL of dimethyl carbonate DMC (10-50mL can be implemented) to the precipitate and stir well, then filter the solution. join in Mol...

Embodiment 3

[0072] A kind of graft polysilane compound PMSVEC40, its structural formula is as follows:

[0073]

[0074] Wherein, the degree of polymerization n is 20; -CH 2 -The number m of chain links is 2; the graft substitution rate x is 0.37.

[0075] The synthetic method of grafted polysilane compound PMSVEC40 specifically comprises the following steps:

[0076] (1) Take 4.56g VEC and 4.40g PMS (mass ratio of VEC and PMS is 1:10~2.5:1 can be implemented), dissolve in THF, add 0.01g AIBN, reflux at 60~70°C for 12h , and the solvent was distilled off under reduced pressure.

[0077] (2) Add n-hexane under the protection of Ar atmosphere, stir to make it fully dissolved. An equal amount of methanol was added for sedimentation, and the supernatant was discarded after centrifugation to obtain a precipitate.

[0078] (3) Add 20mL of dimethyl carbonate DMC (10-50mL can be implemented) to the precipitate and stir well, then filter the solution. join in Molecular sieves reduce the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com