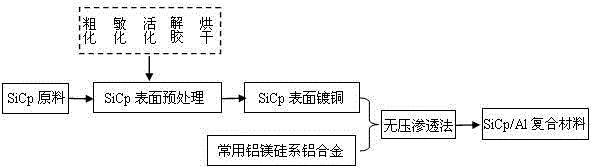

Preparation method of electronic packaging silicon carbide reinforced aluminum-based composite material

A composite material and reinforced aluminum-based technology, applied in metal material coating process, liquid chemical plating, coating, etc., can solve problems such as failure and overheating, achieve compact structure, improve application prospects, and improve wettability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

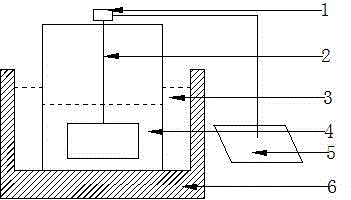

Method used

Image

Examples

Embodiment 1

[0022] (1) SiCp particles with a particle size of about 100 μm are selected as raw materials. First, roughen the SiCp particles, pickle the surface of the particles with an aqueous solution of HF acid with a volume fraction of 20%; then perform sensitization treatment, the formula of the sensitization solution is: 20g / l stannous chloride, 38% concentrated hydrochloric acid The volume fraction is 4%, and the solvent is distilled water. Take the preparation of 500ml sensitizing solution as an example, add 10g of stannous chloride to 20ml of 37% concentrated hydrochloric acid, then add it to distilled water for dilution, and keep stirring to obtain a clear solution. After the sensitization solution was prepared, the coarsened SiCp particles were added and stirred for 10 min. Then carry out activation treatment, the activation solution formula is: 5g / l silver nitrate, appropriate amount of ammonia water (adjust the solution to be clear), and the solvent is distilled water. Take ...

Embodiment 2

[0028](1) SiCp particles with a particle size of about 150 μm are selected as raw materials and pretreated. First, roughen the SiCp particles, pickle the surface of the particles with an aqueous solution of HF acid with a volume fraction of 20%, and then perform sensitization treatment. The formula of the sensitization solution is: stannous chloride 15g / l, 38% concentrated hydrochloric acid The volume fraction is 6%, and the solvent is distilled water. Taking the preparation of 500ml sensitizing solution as an example, add 7.5g of stannous chloride to 30ml of 37% concentrated hydrochloric acid, then add it to distilled water for dilution, and keep stirring to obtain a clear solution. After the sensitization solution was prepared, the coarsened SiCp particles were added and stirred for 12 minutes. Then carry out activation treatment, the activation solution formula is: 6g / l silver nitrate, appropriate amount of ammonia water (adjust the solution to be clear), and the solvent i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com