Pig gall powder preparing process

A processing technology, pig bile technology, applied in powder transportation, medical preparations containing active ingredients, digestive system, etc., can solve the problems of deterioration of active ingredients, reduction of use value of pig bile powder, etc., and achieve good symptom improvement effect, good The effect of treating patients' diseases and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

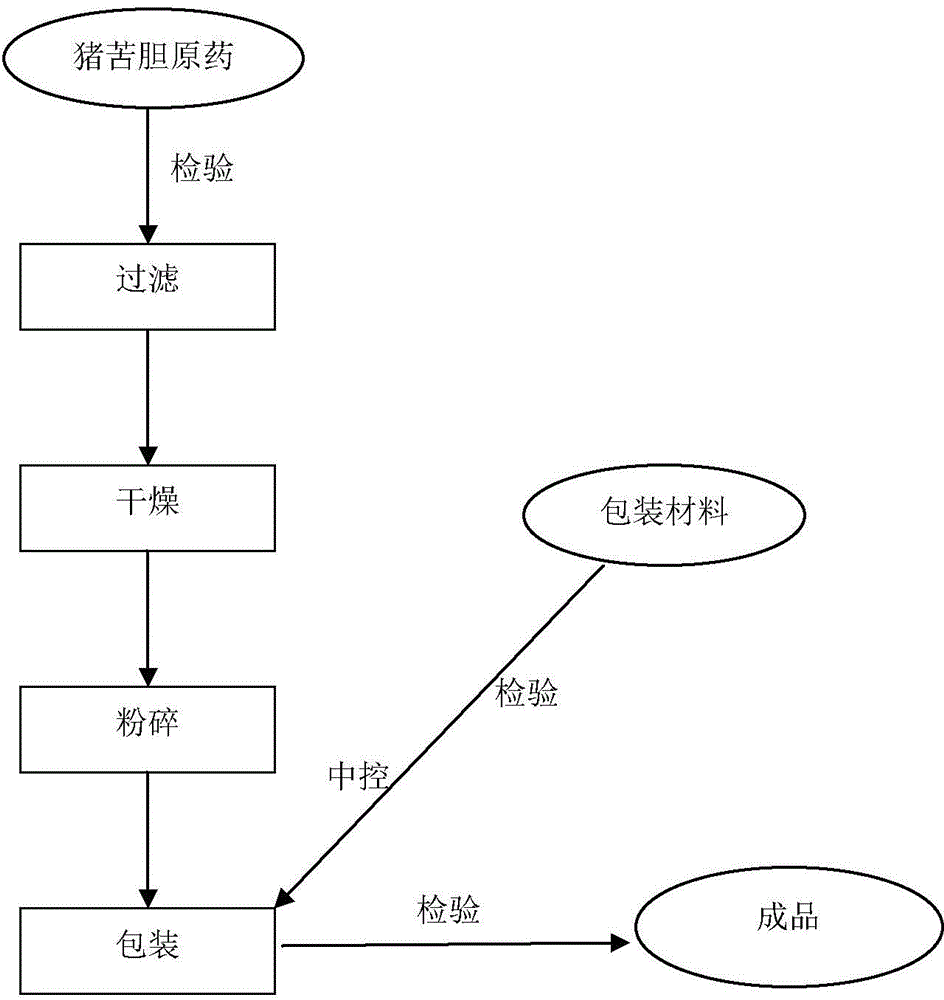

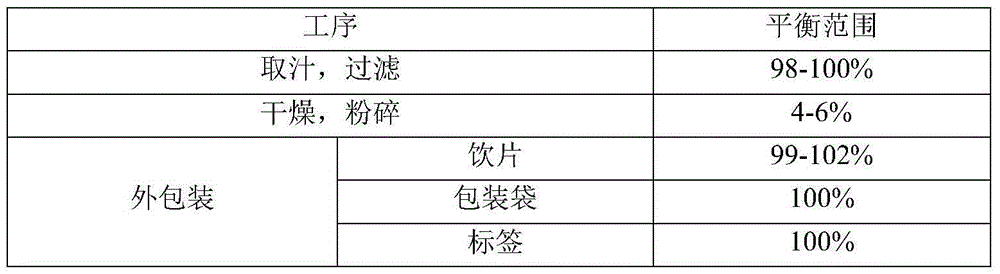

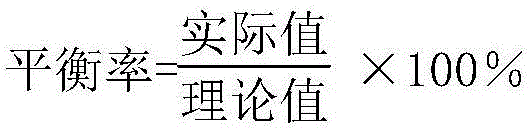

[0033] according to figure 1 As shown in the technological process, take 20kg of the original medicinal material of gallbladder, chop it up, pass through an 80-mesh sieve, and filter to remove the gallbladder residue. The filtrate is transported to a tilting cooking pot and heated to 50°C by steaming. A vacuum pump is installed on the cooking pot, turn on the vacuum pump to generate negative pressure in the cooking pot, control the pressure in the cooking pot to about 0.02MPa, and dry under reduced pressure. When the relative density of the material reaches 0.8, stop feeding the steam, open the lid, and take out the material in the pot after cooling down to below 30°C. Put it into a hot air circulation constant temperature drying oven, spread the plate to a thickness of 1-2cm, and set the drying temperature to 55°C for drying. The material is dried until the moisture content is lower than 10%, taken out, and pulverized by a high-speed universal pulverizer with a screen of 10...

Embodiment 2

[0035]Get pig bile 47kg and place in the first drying equipment, open the steam generator, feed steam and the material in the drying equipment is heated to 70°C. The drying equipment is equipped with a vacuum pipeline, and the vacuum pump is turned on to generate a negative pressure in the drying equipment, and the absolute pressure inside the drying equipment is controlled to 0.07MPa to dry at low pressure and low temperature. When the relative density of the material reaches 1.12, turn off the steam generator, turn on the drying equipment, and take out the material after cooling down to below 30°C. Put it into the hot air circulation constant temperature drying box, the thickness of the plate is 1-3cm, and set the drying temperature at 55°C for low-temperature drying. When the material is dried to a moisture content lower than 5%, take out the material and use 30B-300 high-speed universal crushing Machine is pulverized, and the pulverizer sieve screen is with 100 orders, and...

Embodiment 3

[0037] Get 80kg of the original medicinal material of gall gall, chop it into pieces, pass through an 80-mesh screen, and filter to remove the gallbladder residue. The filtrate is heated to 54°C with steam, and then dried under reduced pressure to 0.02MPa. When the relative density of the material reaches 1.23, the steam is stopped, and the material is naturally cooled to below 25°C with the drying equipment, then taken out, and placed in a hot air circulation constant temperature drying box , the thickness of the paving plate is 1-2cm, and the drying temperature is set at 60°C for low-temperature drying. When the material is dried to a moisture content lower than 8%, the material is taken out and crushed with a 30B-300 high-speed universal pulverizer, and the pulverizer screen is used 100 mesh, 4.7kg of decoction pieces after crushing, and packaged finished product. The water content was 2.9%, sulfur dioxide was not detected, the content of taurine hyodeoxycholic acid was 6.2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com