Biological adsorbent capable of removing fluorine and heavy metals in wastewater, preparation method and application method thereof

A biosorbent and heavy metal technology, applied in chemical instruments and methods, water pollutants, adsorbed water/sewage treatment, etc., can solve problems such as difficult simultaneous removal of fluorine and heavy metals, secondary pollution adsorption performance, complex preparation process, etc. , to achieve the effect of short cycle, mild experimental operating conditions and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Weigh 200g of cleaned potatoes, peel and chop them, then add 1L of deionized water and boil for 30 minutes. Then filter with gauze to obtain the filtrate, add 0.5 g of magnesium sulfate, 1 g of sodium dihydrogen phosphate, and 20 g of glucose, add distilled water to make the volume to 1 L, and sterilize at 115° C. for 20 minutes to obtain a liquid medium for use. Collect the fungal spores of "Aspergillussp.F-1" cultivated on the plate, press 10 6 -10 7 The amount of inoculum per milliliter was inoculated into sterilized medium, and then placed on a shaker with a rotation speed of 175 rpm at 37°C for 3 days to obtain the desired bacterial solution for use. Take 10mL bacterial liquid and 10mL 0.1mol / LAl 2 (SO 4 ) 3 .6H 2 O was added to a flat-bottomed flask, the concentration of bacteria in the mixed solution was 8g / L, and the concentration of aluminum sulfate was 0.05mol / L. After stirring evenly, adjust the pH to about 5.5 with NaOH, then continuously stirred and so...

Embodiment 2

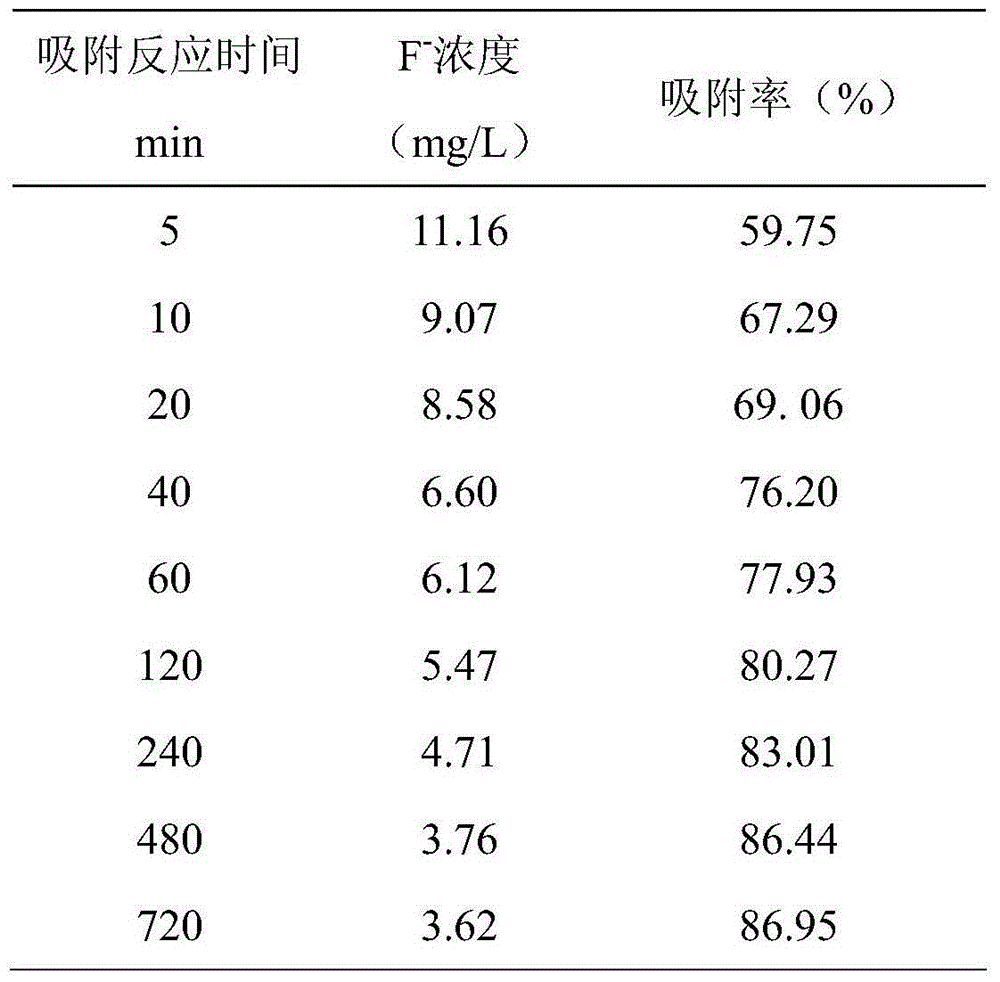

[0024] At room temperature, with 50 mg of the biosorbent prepared in Example 1, the initial pH of 100 mL was 4.5, and the fluoride ion concentration was 27.73 mg L -1 The solution undergoes adsorption reaction, wherein the reaction time is controlled at 5, 10, 20, 40, 60, 120, 240, 480, 720 min. After the reaction, the mixed solution was filtered and collected in a dry beaker, and the concentration of fluoride ions in the filtrate was determined by a fluoride ion selective electrode method. Table 1 shows the solution concentration and adsorption rate of fluoride ions under different reaction times.

[0025] Table 1

[0026]

Embodiment 3

[0028] Use 100mg of the biosorbent prepared in Example 1 to carry out adsorption reaction on 100mL solution with an initial pH of 6.0 and a fluoride ion concentration of 179.1 mg / L. After shaking the reaction for 720 minutes, the fluoride ion removal rate was 54.8%. The amount reaches 98.2mg / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com