Bi0.92Ho0.08Fe0.97Mn0.03O3-Zn1-xNixFe2O4 multiferroic composite film and preparation method thereof

A zn1-xnixfe2o4, composite film technology, applied in the field of functional materials, can solve the problems of difficult to obtain hysteresis loops, limit the application of BFO, and easily generate vacancies, etc., and achieve the effect of aggravating structural distortion, improving ferromagnetism, and reducing content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

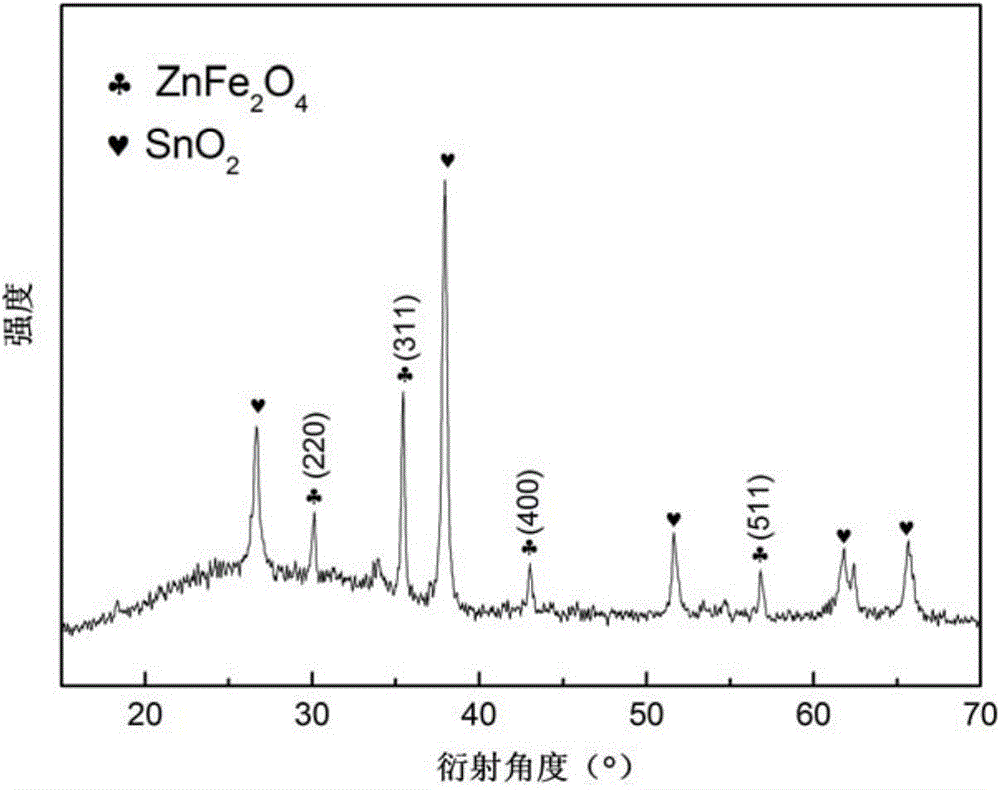

Embodiment 1

[0033] Step 1, zinc nitrate and ferric nitrate are dissolved in ethylene glycol methyl ether at a molar ratio of 1:2, after stirring for 30 minutes, acetic anhydride is added to obtain a stable ZnFe with a Fe ion concentration of 0.15mol / L 2 o 4 Precursor, ZnFe 2 o 4 The volume ratio of ethylene glycol methyl ether and acetic anhydride in the precursor solution is 3:1;

[0034] Step 2, bismuth nitrate, holmium nitrate, ferric nitrate and manganese nitrate are dissolved in the solvent (excessive 5% of bismuth nitrate) in a molar ratio of 0.92:0.08:0.97:0.03 to obtain a stable metal ion total concentration of 0.3mol / L Bi 0.92 Ho 0.08 Fe 0.97 mn 0.03 o 3 Precursor solution; wherein the solvent is a mixed solution of ethylene glycol methyl ether and acetic anhydride in a volume ratio of 3:1;

[0035] Step 3, choose the FTO / glass substrate as the substrate, place the cut FTO / glass substrate in detergent, acetone, and ethanol in sequence for ultrasonic cleaning, rinse the su...

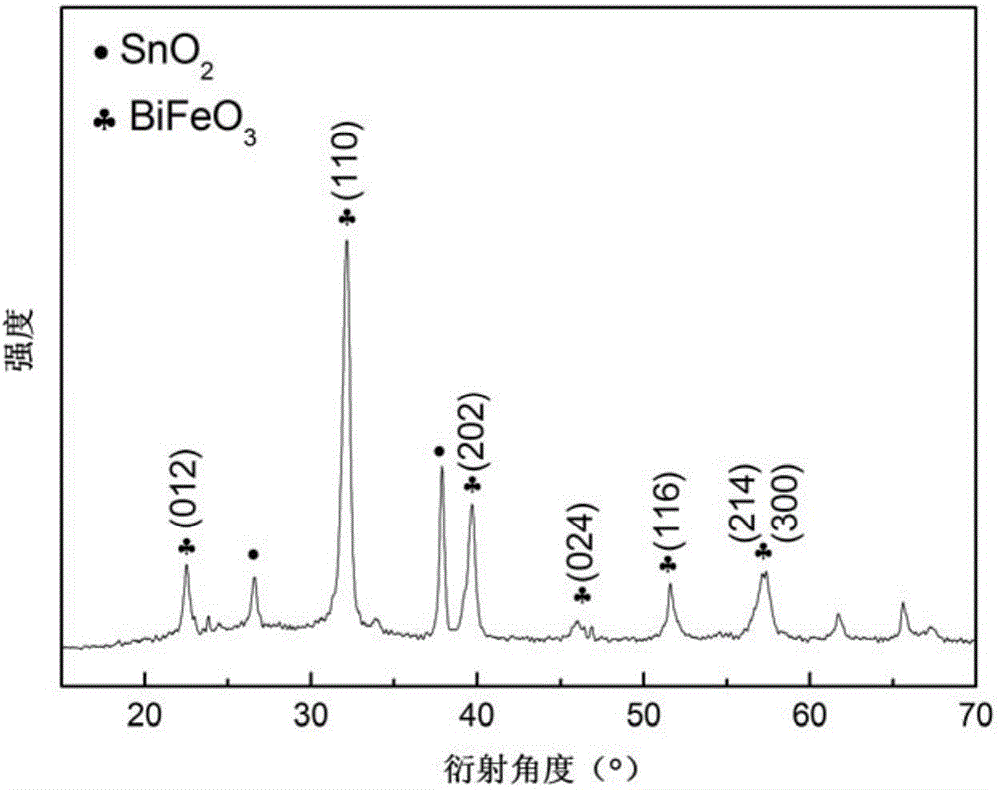

Embodiment 2

[0041] In step 1, zinc nitrate, nickel acetate and iron nitrate are dissolved in ethylene glycol methyl ether in a molar ratio of 0.75:0.25:2, and after stirring for 30 minutes, acetic anhydride is added to obtain a stable Fe ion concentration of 0.1mol / L. Zn 0.75 Ni 0.25 Fe 2 o 4 Precursor, Zn 0.75 Ni 0.25 Fe 2 o 4 The volume ratio of ethylene glycol methyl ether and acetic anhydride in the precursor solution is 3:1;

[0042] Step 2, dissolving bismuth nitrate, holmium nitrate, ferric nitrate and manganese nitrate in a molar ratio of 0.92:0.08:0.97:0.03 in a solvent (excessive 5% bismuth nitrate) to obtain a stable concentration of 0.2mol / L total metal ion concentration Bi 0.92 Ho 0.08 Fe 0.97 mn 0.03 o 3 Precursor solution; wherein the solvent is a mixed solution of ethylene glycol methyl ether and acetic anhydride in a volume ratio of 3:1;

[0043] Step 3, choose the FTO / glass substrate as the substrate, place the cut FTO / glass substrate in detergent, acetone, ...

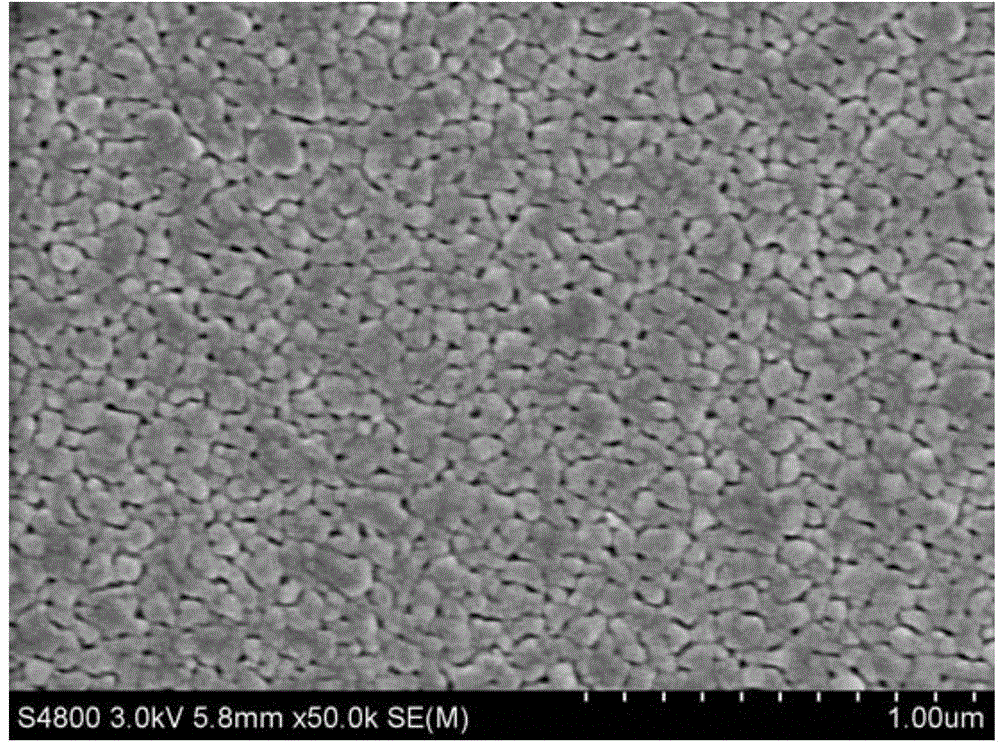

Embodiment 3

[0048] Step 1, dissolving zinc nitrate, nickel acetate and iron nitrate in a molar ratio of 0.5:0.5:2 in ethylene glycol methyl ether, stirring for 30 minutes, then adding acetic anhydride to obtain a stable Fe ion concentration of 0.2mol / L Zn 0.5 Ni 0.5 Fe 2 o 4 Precursor, Zn 0.5 Ni 0.5 Fe 2 o 4 The volume ratio of ethylene glycol methyl ether and acetic anhydride in the precursor solution is 2.5:1;

[0049] Step 2, dissolving bismuth nitrate, holmium nitrate, ferric nitrate and manganese nitrate in a molar ratio of 0.92:0.08:0.97:0.03 in a solvent (excessive 5% bismuth nitrate) to obtain a stable concentration of 0.2mol / L total metal ion concentration Bi 0.92 Ho 0.08 Fe 0.97 mn 0.03 o 3 Precursor solution; wherein the solvent is a mixed solution of ethylene glycol methyl ether and acetic anhydride in a volume ratio of 2.5:1;

[0050] Step 3, choose the FTO / glass substrate as the substrate, place the cut FTO / glass substrate in detergent, acetone, and ethanol in s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com