Rapid dry type water-based epoxy ester emulsion and preparation method and application thereof

An epoxy ester, quick-drying technology, applied in coatings, anti-corrosion coatings, etc. The process is not easy to control and other problems, to achieve the effect of good self-crosslinking, dense paint film, good hydrolysis resistance and storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment aims to demonstrate the preparation method of quick-drying water-based epoxy ester emulsion, and its preparation steps are as follows:

[0052] (1) Add 140g of E-12 epoxy resin, 65g of linoleic acid, and 75g of soybean oil into a four-necked flask, and gradually heat up to 130°C. After the material melts, start stirring, continue to heat up to 180°C, and react at this temperature to After the acid value is less than 5mgKOH / g, add 38g soy oil;

[0053] (2) Cool down to 150°C, mix 20g of methyl methacrylate, 35g of styrene, 25g of methacrylic acid and 3g of tert-butyl peroxybenzoate evenly, and then drop them into a four-necked flask gradually, and the dropping time is controlled at 4 to 8 hours, after the dropwise addition, keep warm for 3 to 4 hours until the conversion rate is 98±2%;

[0054] (3) Raise the temperature to 190°C, and after reacting for 2 to 3 hours, start to measure the acid value, and after the acid value is 40mgKOH / g, start to cool dow...

Embodiment 2

[0059] This embodiment aims to demonstrate the preparation method of quick-drying water-based epoxy ester emulsion, and its preparation steps are as follows:

[0060] (1) Add 140g E-12 epoxy resin, 56g tung oil, and 80g tall oleic acid into a four-necked flask, gradually heat up to 130°C, start stirring after the material melts, continue to heat up to 180°C, and react at this temperature to After the acid value is less than 5mgKOH / g, add 42g tall oleic acid;

[0061] (2) Cool down to 150°C, mix 20g of isobutyl methacrylate, 35g of vinyl toluene, 25g of methacrylic acid and 3g of tert-butyl peroxybenzoate evenly, and gradually add them dropwise into a four-necked flask. Control it within 4 to 8 hours, after the dropwise addition, keep it warm for 3 to 4 hours until the conversion rate is 98±2%;

[0062] (3) Raise the temperature to 190°C, and after reacting for 2 to 3 hours, start to measure the acid value, and after the acid value is 40mgKOH / g, start to cool down;

[0063] (...

Embodiment 3

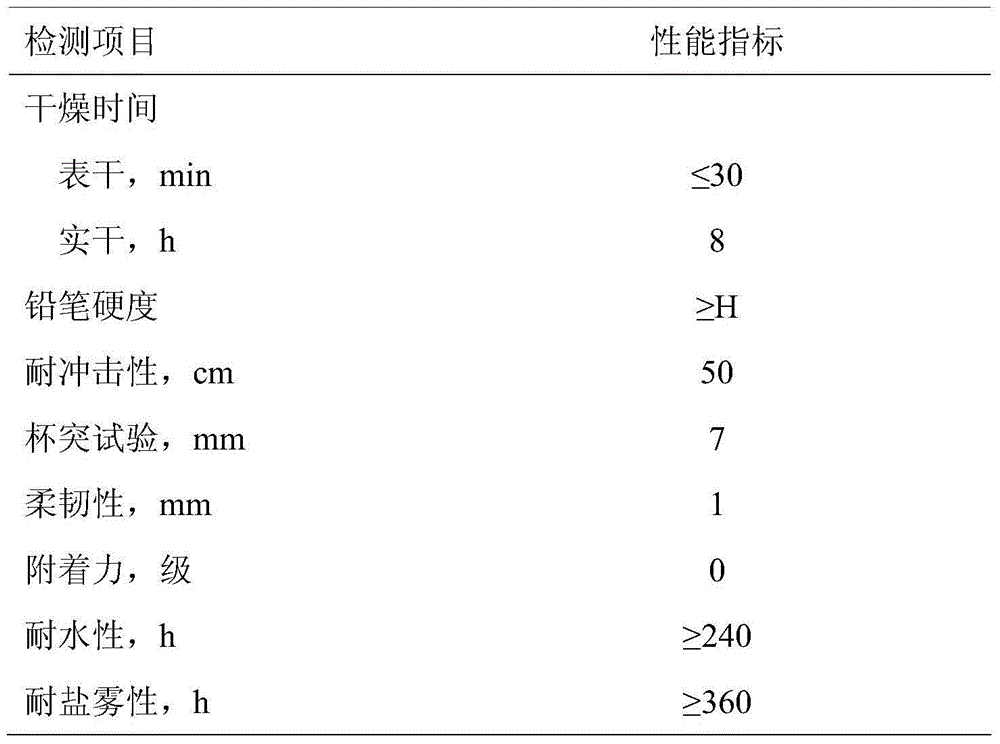

[0069] This embodiment is intended to demonstrate the method for preparing antirust primer with quick-drying water-based epoxy ester emulsion as base material, and its preparation steps are as follows:

[0070] (1) Add 450g of quick-drying water-based epoxy ester emulsion, 170g of deionized water, 4g of N,N-dimethylethanolamine, 4g of defoamer BYK-024 and 3g of wetting and dispersing agent BYK-190 into the high-speed dispersion kettle , Stir at a speed of 600-800rpm for 15-30 minutes to mix the materials evenly;

[0071] (2) Add 68g iron oxide red, 150g zinc phosphate, 84g precipitated barium sulfate and 56g talcum powder CMS-888, grind with a sand mill until the fineness is less than 30 microns;

[0072] (3) Add 4g of water-based drier HLD-061 and 7g of thickener WT-202, and stir at a speed of 600-800rpm for 1-1.5 hours to mix the materials evenly;

[0073] (4) Detect the pH value, add an appropriate amount of neutralizer, and adjust the pH value to 7.5-8.5;

[0074] (5) Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com