Graphene/SDS (Sodium Dodecyl Sulfate)-modified carbon paste electrode and preparation method thereof

A carbon paste electrode and graphene technology, applied in the field of electrochemical analysis, can solve the problems of poor electrode stability and reproducibility, and achieve good selectivity and sensitivity, good reproducibility, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

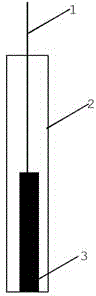

[0050] A carbon paste electrode modified by graphene / SDS, the schematic diagram of which is shown in figure 1 As shown, the carbon paste electrode modified by graphene / SDS is composed of an electrode lead 1, a polytetrafluoroethylene tube 2 with an inner diameter of 3 mm, and a carbon paste 3 filled in the polytetrafluoroethylene tube 2. The electrode One end of the lead wire 1 is directly inserted into the carbon paste 3, and the other end is led out of the polytetrafluoroethylene tube 2;

[0051] The electrode lead 1 is a copper rod;

[0052] The inner diameter of the polytetrafluoroethylene pipe 2 is 3mm;

[0053] The carbon paste 3 is formed by uniformly grinding graphite powder, solid paraffin oil and graphene / SDS composite material, wherein the amount of graphite powder, solid paraffin oil and graphene / SDS composite material is calculated by mass ratio, i.e. graphite Powder: solid paraffin oil: graphene / SDS composite material is 4:1.33:1;

[0054] In the described gra...

Embodiment 1

[0063] As a contrast, a carbon paste electrode for comparison was prepared, that is, there was no common bare carbon paste electrode modified by graphene / SDS, and its preparation process was the same as that of the carbon paste electrode modified by graphene / SDS in the above-mentioned embodiment 1. It's just that carbon paste 3 is made by uniformly mixing 240mg graphite powder and 80mg solid paraffin oil.

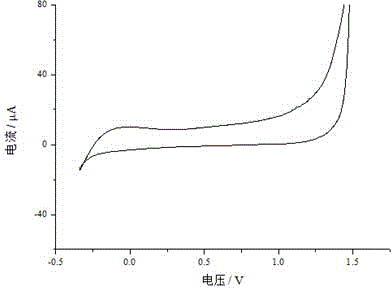

[0064] The carbon paste electrode modified by the graphene / SDS obtained in Example 1 was placed in PBS solution (phosphate buffer solution) of 0.1M and pH=7.0 for cyclic voltammetry scanning, and the scanning rate was 50mV / s, and the resulting cyclic voltammetry safety curve as figure 2 shown, from figure 2 It can be seen that the graphene / SDS modified carbon paste electrode has a wider electrochemical window and a lower background current, and with repeated scanning, the response current and potential have no obvious changes, which shows that the The invented graphene / ...

Embodiment 2

[0070] A carbon paste electrode modified by graphene / SDS is composed of an electrode lead, a polytetrafluoroethylene tube with an inner diameter of 3mm, and a carbon paste filled in the polytetrafluoroethylene tube. One end of the electrode lead is inserted directly into the carbon paste , and the other end leads out of the Teflon tube;

[0071] The electrode leads are copper rods;

[0072] The inner diameter of the polytetrafluoroethylene pipe is 3mm;

[0073] The carbon paste is uniformly mixed by grinding graphite powder, solid paraffin oil and graphene / SDS composite material, wherein the amount of graphite powder, solid paraffin oil and graphene / SDS composite material is calculated by mass ratio, i.e. graphite powder : Solid paraffin oil: graphene / SDS composite material is 3:1.07:1;

[0074] In the described graphene / SDS composite material, calculated by mass ratio, graphene: SDS is 1:0.3.

[0075] The preparation method of the above-mentioned carbon paste electrode mod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com