Preparation method of diesel functional component, obtained catalyst for preparing diesel component and application of catalyst

A technology of functional components and catalysts, which is applied in the development of solid catalysis and diesel functional components, can solve the problems of increasing the difficulty of product separation, corrosive environment of equipment, and high neutralization cost, and achieves convenient continuous operation, prevents environmental pollution, The effect of eliminating corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention discloses a preparation method of a diesel functional component. The preparation method comprises the following steps:

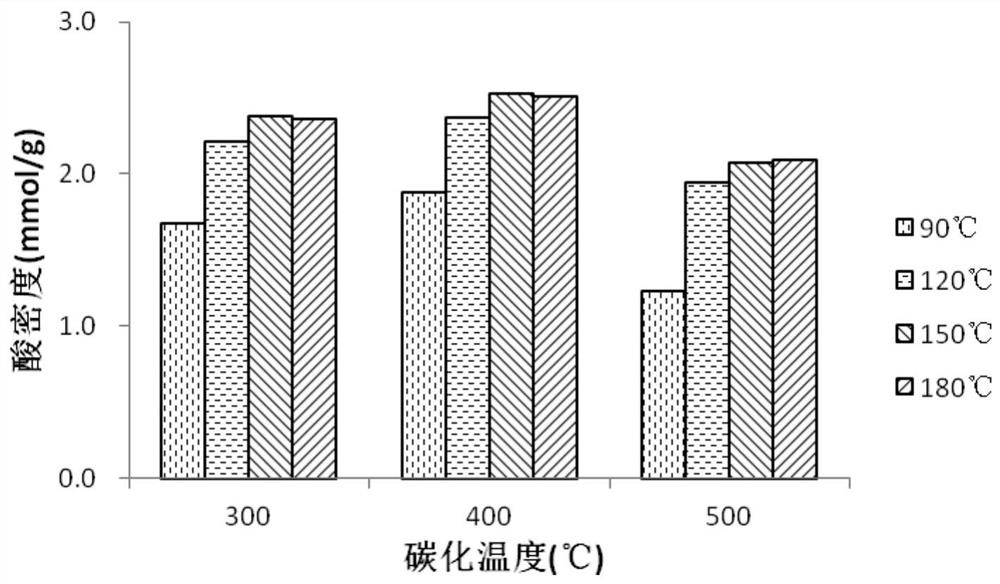

[0032] Step 1, pyrolyzing Jatropha japonica shell and oil meal to obtain carbonized product, then adding concentrated sulfuric acid and heating to obtain black solid;

[0033] Step 2, adding polyethylene solution to the black solid of step 1, drying and grinding to obtain component A;

[0034] Step 3, one or more of the group consisting of metal oxide, acidic substance and ammonium-containing compound are mixed and roasted to obtain component m;

[0035] Step 4, the α-Al 2 O 3 , one or more of the group consisting of acidic substances and ammonium-containing compounds are mixed and calcined to obtain component n; and

[0036] Step 5, mixing components m and n, then adding polyvinyl alcohol solution, roasting and grinding into powder to obtain component B, and mixing component B and component A obtained in step 2 to obtain a catalyst f...

Embodiment 1

[0052] Jatropha husk and oil meal were heated at 200 °C at a heating rate of 5 °C / min in N 2 Pyrolysis was carried out under air flow for 1 h to promote partial carbonization in situ. Add 200 mL of oleum to 20 g of carbonized product, in N 2 The mixture was heated from room temperature to 50°C under airflow. Foaming occurs during heating. After heating at 50 °C for 16 h, a black solid was obtained, excess sulfuric acid was removed, and the black solid was repeatedly washed with a large amount of distilled water at 25 °C until the filtrate was neutral and free of sulfate ions. After filtration, it was dried in an oven at 25°C overnight, ground into powder, added with 8% polyethylene solution by mass, dried in an oven at 85°C for 30 hours, and ground into fine particles to prepare component A; magnesium oxide and glacial acetic acid were mixed with Mixed with ammonium bicarbonate and calcined at 700℃ for 20min, α-Al 2 O 3 The powder is mixed with ammonium hydroxide and ammo...

Embodiment 2

[0055] Jatropha husk and oil meal were heated at 400 °C at a heating rate of 5 °C / min in N 2 Pyrolysis was carried out under air flow for 2 h to promote in-situ partial carbonization. Add 200 mL of oleum to 20 g of carbonized product, in N 2 The mixture was heated from room temperature to 150°C under airflow. Foaming occurs during heating. After heating at 150 °C for 16 h, a black solid was obtained, excess sulfuric acid was removed, and the black solid was repeatedly washed with a large amount of distilled water at 80 °C until the filtrate was neutral and free of sulfate ions. After filtration, it was dried in an oven at 70°C overnight, ground into powder, added with 10% polyethylene solution, dried in an oven at 70°C for 48 hours, and ground into fine particles to prepare component A; the oxide was mixed with glacial acetic acid, hydrogen Ammonium oxide and ammonium bicarbonate were mixed and calcined at 800℃ for 15min, α-Al 2 O 3 The powder was calcined at 900°C for 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com