Gas-phase analytical method for rapid determination of characteristic polymeric materials in mixtures

A technology of polymer materials and analysis methods, which is applied in the field of gas-phase analysis for the rapid determination of characteristic polymer materials in mixtures, and can solve problems such as poor specificity, difficult analysis, and inability to be detected by optical detectors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

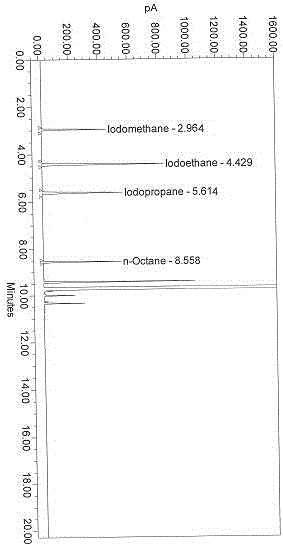

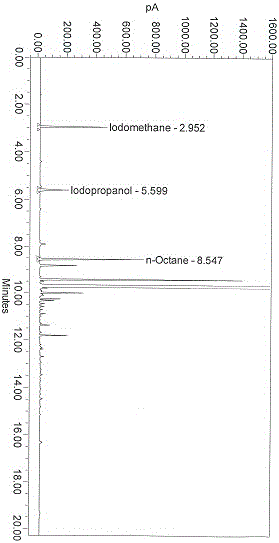

Image

Examples

Embodiment 1

[0022] Determination of the content and specification of hypromellose in quetiapine fumarate sustained-release tablets (Seruquel®, specification: 200mg):

[0023] (1), instruments and conditions

[0024] Gas chromatograph: American Agilent 7890A chromatographic system and workstation;

[0025] Chromatographic column: Agilent DB-1 Fused Silica, 0.53mm×30m, bonded with 3μm layer of G1;

[0026] Injection port temperature: 250°C; Sampling method: split injection 40:1; Carrier gas: high-purity helium, constant flow rate 4.2 milliliters / minute; Programmable temperature rise: initial temperature 50°C, keep 3 minutes, with Rise to 100°C at 10°C / min, then rise to 250°C at 34.9°C / min, hold for 8 minutes; FID detection port temperature: 280°C, injection volume 1μL;

[0027] (2), experimental steps

[0028] Transfer about 200mg of quetiapine fumarate tablet powder to a reaction flask, add 2ml of internal standard solution and 2ml of adipic acid solution to the reaction flask, then add...

Embodiment 2

[0038] Determination of the content and specification of hypromellose in the core of nifedipine sustained-release tablets (NifedicalTM, specification: 30mg):

[0039]Hypromellose contains methoxy and isopropoxy groups, which can be converted into iodide for content determination. Since the active ingredient nifedipine in the core of the nifedipine sustained-release tablet contains methoxy groups, Therefore, it will interfere with the determination of hypromellose. According to the solubility difference between the two, use the organic solvent ethyl acetate to separate nifedipine and then measure the content of hypromellose;

[0040] (1) Instruments and conditions

[0041] Gas chromatograph: American Agilent 7890A chromatographic system and workstation;

[0042] Chromatographic column: Agilent DB-1 Fused Silica, 0.53mm×30m, bonded with 3μm layer of G1;

[0043] Injection port temperature: 250°C; Sampling method: split injection 40:1; Carrier gas: high-purity helium, constant ...

Embodiment 3

[0053] Glipizide sustained-release tablet (specification: 50mg), simultaneous determination of the content and specification of Eudragit and ethylcellulose in the coating:

[0054] Eudragit contains methoxy groups, and ethyl cellulose contains ethoxy groups. Through the reaction, they can be converted into methyl iodide and ethyl iodide respectively for the content determination of Eudragit and ethyl cellulose. Another polymer polyethylene glycol in the release tablet coating also contains ethoxy groups, so it will interfere with the determination of ethyl cellulose. It has good solubility and is insoluble in water, and Eudragit is also basically insoluble in water, so polyethylene glycol is separated with water to determine Eudragit and ethyl cellulose;

[0055] (1) Instruments and conditions

[0056] Gas chromatograph: American Agilent 7890A chromatographic system and workstation;

[0057] Chromatographic column: Agilent DB-1 Fused Silica, 0.53mm×30m, bonded with 3μm layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com