Preparation method of water retention type controlled-release urea formaldehyde compound fertilizer

A urea-formaldehyde slow-release and compound fertilizer technology, which is applied to urea compound fertilizers, fertilizer mixtures, nitrogen fertilizers, etc., can solve the problems of mutual influence, weakened water-retaining slow-release effect, and poor water-retaining effect of water-retaining fertilizers, so as to prevent rapid collapse of water-absorbing swelling solution, good slow release of nitrogen, and low content of free formaldehyde

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

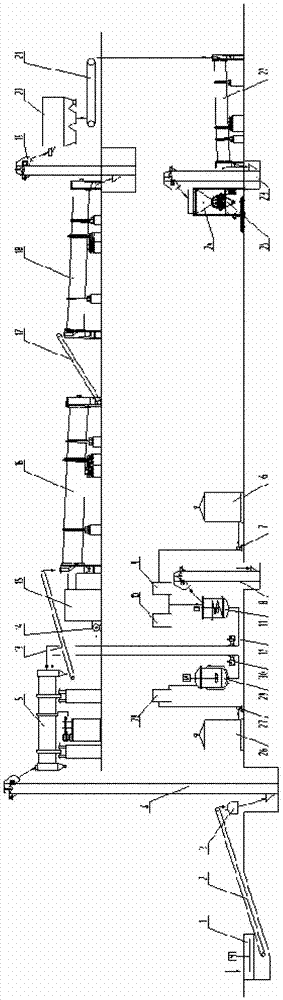

Image

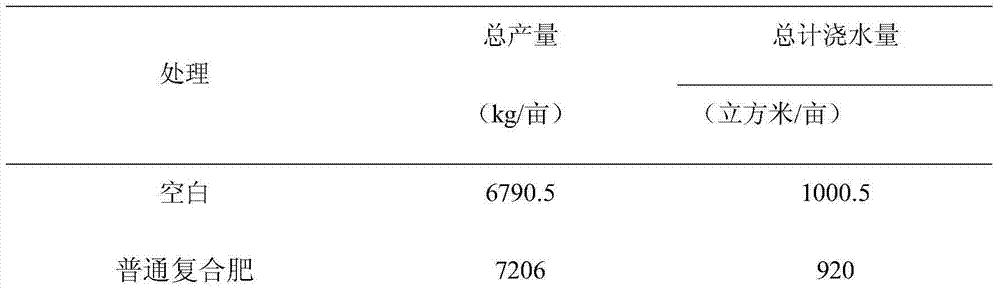

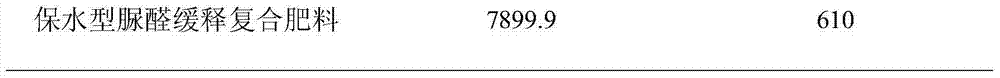

Examples

Embodiment 1

[0041] A method for preparing a water-retaining urea-formaldehyde slow-release compound fertilizer, the steps of the production method are as follows:

[0042] (1) After adding water and oxidized starch in the polycondensation reactor, the temperature was raised to 85°C for gelatinization for 20 minutes, and urea with a nitrogen content of 46wt% was added to the polycondensation reactor through the urea feeding device, and the polycondensation was fed through the formaldehyde feeding device Add formaldehyde solution with a concentration of 37wt% into the reaction kettle, stir the urea to dissolve, add borax to the polycondensation reaction kettle to adjust the pH value to 8.7, raise the temperature to 60°C, and react at a constant temperature for 70 minutes, then add phosphoric acid with a concentration of 20wt% to adjust the pH value to 5.3, react at a constant temperature of 66°C for 45 minutes; then adjust the pH value to 7.0 with boric acid with a concentration of 20wt%, an...

Embodiment 2

[0055] Embodiment 2: a kind of preparation method of water-retaining type urea-formaldehyde slow-release compound fertilizer, step is with embodiment 1, and difference is that the mass ratio of step (2) starch and acrylic acid is: 1:0.1, and the mass ratio of starch and acrylamide is :1:0.03.

Embodiment 3

[0056] Embodiment 3: a kind of preparation method of water-retaining type urea-formaldehyde slow-release compound fertilizer, step is with embodiment 1, and difference is that the initiator described in step (2) is ammonium persulfate, and mineral soil is kaolin, the consumption of ammonium persulfate 5% of the mass of the starch, the amount of the crosslinking agent is 0.3% of the mass of the starch, and the amount of kaolin is 8% of the mass of the starch.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com