Preparation method of mash

A technology for mash and enzymatically hydrolyzed sugar solution, which is applied in the directions of microorganism-based methods, methods using microorganisms, biochemical equipment and methods, etc., can solve the problems of incomplete reaction, long production cycle, reduced production efficiency, etc. The effect of eliminating feedback inhibition, reducing sugar liquid loss and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

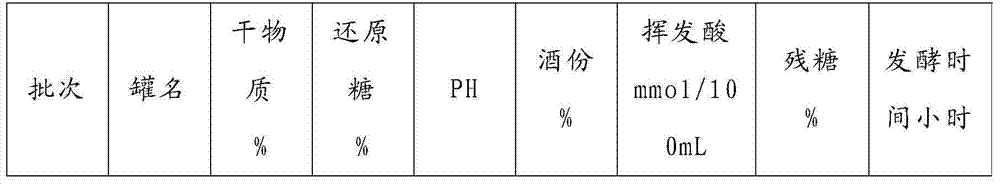

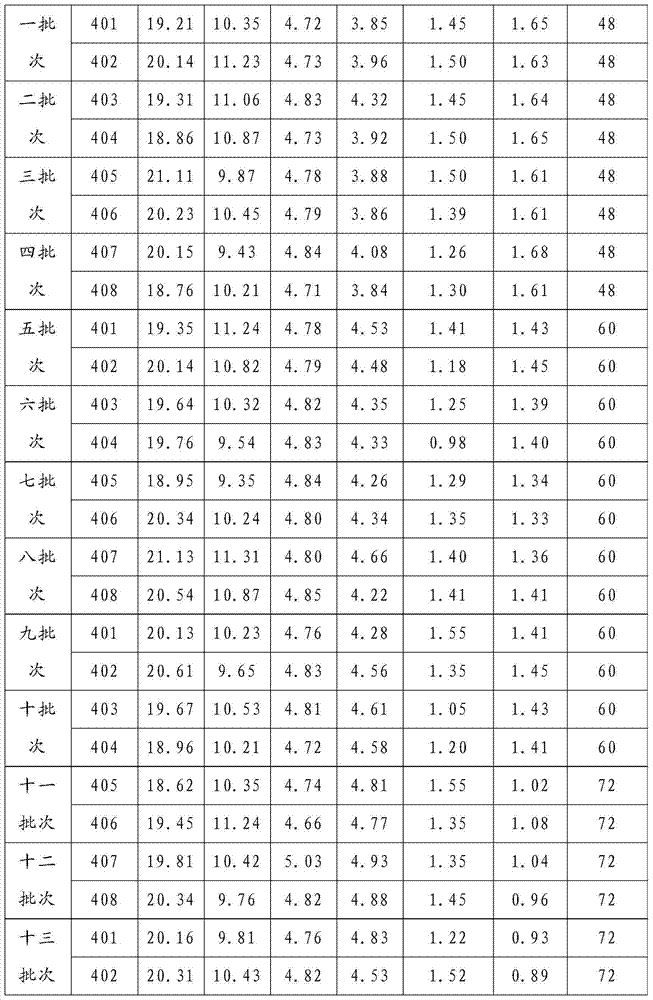

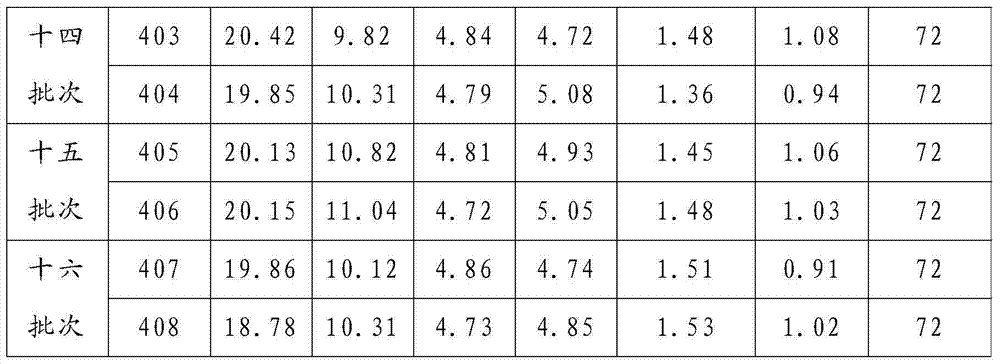

Image

Examples

preparation example Construction

[0028] The embodiment of the invention discloses a method for preparing mash, comprising the following steps:

[0029] (A) Pretreating the crop stalks through steam explosion;

[0030] (B) adding cellulase and domesticated Saccharomyces cerevisiae to the pretreated product for enzymolysis and fermentation to obtain mash;

[0031] The domestication method of described saccharomyces cerevisiae is:

[0032] The activated Saccharomyces cerevisiae is cultured in the mixture of corn mash and enzymatic sugar liquid to obtain small wine mother; the mass ratio of the corn mash and enzymatic sugar liquid is (80-90): (10-20 );

[0033] The small wine tree is subjected to multi-generation expansion culture in the mixture of corn mash and enzymatic sugar liquid to obtain Dajiu Fu; in the first generation of expanded culture, the mass ratio of corn mash and enzymatic sugar liquid is (60~ 70): (30-40); in each subsequent generation of expanded culture, gradually increase the proportion of...

Embodiment 1

[0052] (1) Domestication of Saccharomyces cerevisiae:

[0053] Prepare activation medium: mix 20 ml of 2% glucose, 0.375 g of diammonium phosphate, 0.375 g of urea, and 0.25 g of magnesium sulfate, and add water to 500 ml.

[0054] Preparation of enzymatic sugar solution: maintain 1000 kg of crop stalks at a steam pressure of 1.4 MPa for 10 minutes to obtain a pretreated product; quickly depressurize to obtain a steam explosion pretreated product; % Add cellulase, carry out enzymatic hydrolysis under the conditions of normal pressure, 45° C., and pH 4.8, to obtain enzymatic hydrolyzed sugar solution.

[0055] Add 0.5 g of dry yeast to the activation medium, shake well, and activate in a 38° C. water bath for 1 hour.

[0056] Add 20 grams of the activated yeast to 90 ml of corn mash and 10 ml of enzymatic sugar solution, place in a water bath at 30° C., ventilate and cultivate for 10 hours to obtain Xiaojiufu.

[0057] Add 150ml of mature xiaojiufu to the mixture of 240ml cor...

Embodiment 2

[0065] (1) Domestication of Saccharomyces cerevisiae:

[0066] Prepare activation medium: mix 20 ml of 2% glucose, 0.375 g of diammonium phosphate, 0.375 g of urea, and 0.25 g of magnesium sulfate, and add water to 500 ml.

[0067] Preparation of enzymatic sugar solution: maintain 1,000 kg of crop straw at a steam pressure of 1.5 MPa for 12 minutes to obtain a pretreated product; quickly depressurize to obtain a steam explosion pretreated product; % Add cellulase, carry out enzymatic hydrolysis under the conditions of normal pressure, 45° C., and pH 4.8, to obtain enzymatic hydrolyzed sugar solution.

[0068] Add 0.5 g of dry yeast Saccharomyces cerevisiae to the activation medium, shake well, and activate in a water bath at 36° C. for 1.2 hours.

[0069] Add 20 grams of the activated yeast to 85 ml of corn mash and 15 ml of enzymatic sugar solution, adjust the pH to 4.5, place it in a water bath at 28° C., and cultivate it with ventilation for 12 hours to obtain Xiaojiufu. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com