Method for preparing carbon quantum dot by carbonizing ketone under alkaline condition

A technology of carbon quantum dots and alkaline conditions, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems of complex operation and high cost, and achieve uniform particle size distribution and energy efficiency. The effect of less consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

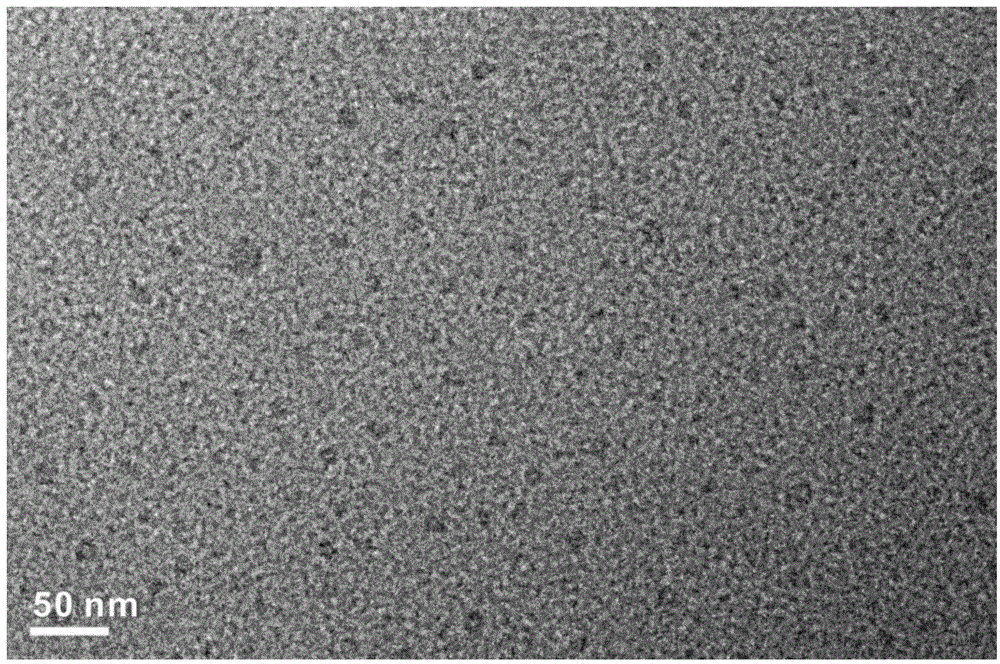

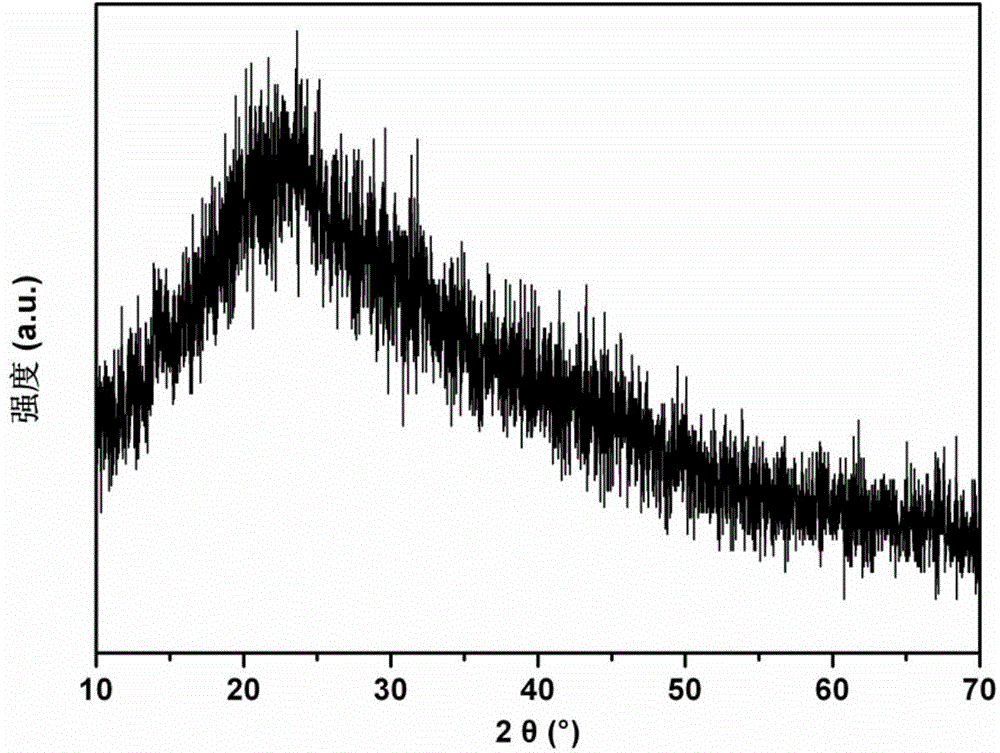

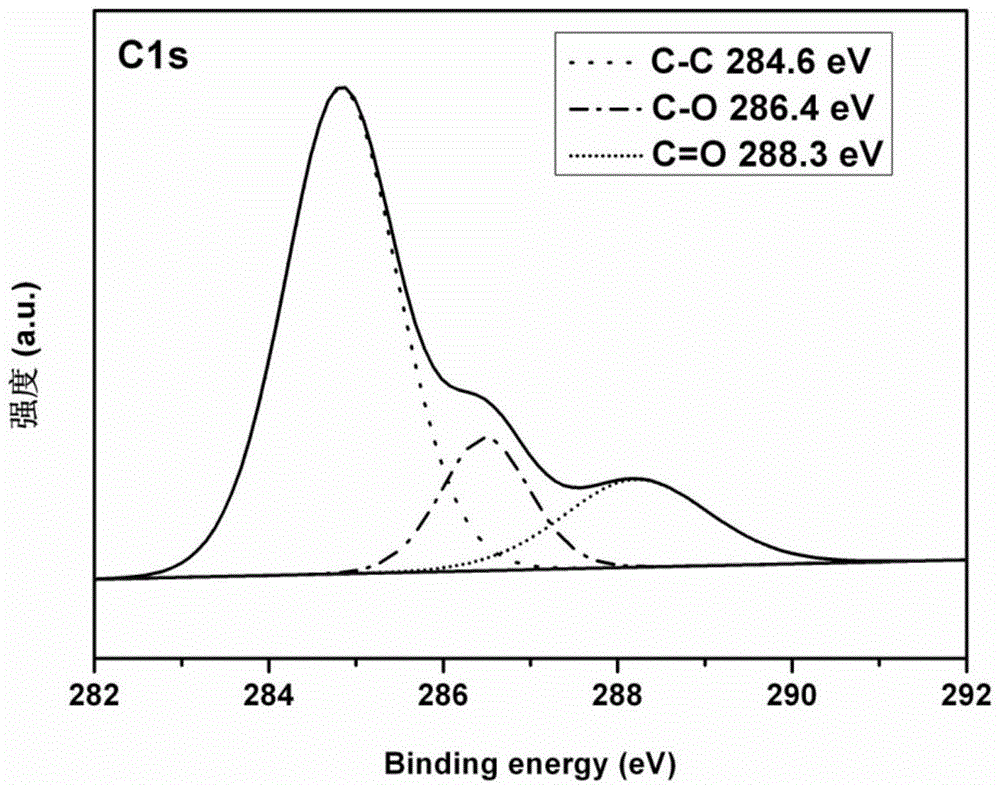

[0024] Prepare a 1.5mol / L sodium hydroxide-acetone mixture, let it stand at room temperature (25°C) for 240h, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 12000r / min for 10min, wash with deionized water for 5 Once, vacuum-dried at 80°C for 24 hours to obtain solid carbon quantum dots. Its transmission electron microscope picture is figure 1 , The particle size is relatively uniform, about 10nm. figure 2 According to its X-ray diffraction (XRD) spectrum, the obtained carbon quantum dots are amorphous carbon. image 3 For its photoelectron spectrum (XPS), the 284.6eV peak corresponds to the graphitized sp2 carbon atom, the 286.4eV and 288.3eV peaks correspond to the C-O and C=O carbon atoms, and the carbon quantum dots contain oxygen functional groups. Figure 4 Its fluorescence spectrum diagram has the characteristics of changing with the change of excitation light spectrum. Figure 5 For the photos of different reacti...

Embodiment 2

[0026] Prepare a 0.5mol / L sodium hydroxide butanone mixture, let it stand at room temperature for 360h, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 16000r / min for 5min, wash 5 times with deionized water, and Vacuum drying at 120° C. for 12 hours to obtain carbon quantum dot solids with uniform particle size.

Embodiment 3

[0028] Prepare 5mol / L sodium hydroxide acetylacetone (2,4-pentanedione) mixed solution, let it stand for 120h, add an appropriate amount of concentrated hydrochloric acid, adjust its pH to neutral, centrifuge at 8500r / min, use deionized Washing with water for 5 times, and drying in vacuum at 150° C. for 4 hours to obtain solid carbon quantum dots with uniform particle size.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com