Efficient and safe method for synthesizing carbonic ester by using oxidative carbonyl

A technology of oxo synthesis and oxidative carbonylation, applied in the direction of carbon monoxide and oxygen preparation, purification/separation of carbonate/haloformate, chemical instruments and methods, etc., can solve catalyst separation, recovery and corrosion, increase equipment Investment, operating costs, large-scale production equipment and other issues, to achieve the effect of great industrial application prospects, elimination of safety hazards, and efficient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

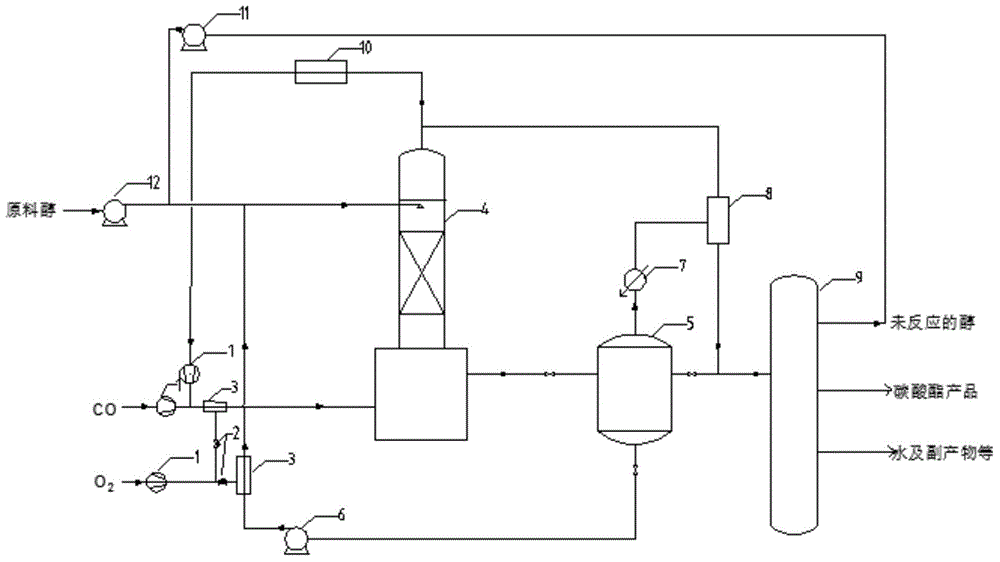

Method used

Image

Examples

Embodiment 1

[0036] 8 kilograms of industrial-grade copper bromide, 4 kilograms of industrial-grade 4-methylquinolines are packed into a 300-liter reactor with packed tower, 110 kilograms of ethanol are packed into, ethylene carbonate 10L is added, and the compressor pressure is started. Enter CO, start the compressor and press O 2 , using a flow controller to control the amount of oxygen so that CO and O 2 The ratio of the intake air volume is 4:1, the total pressure is 3.5MPa, the reactor is heated to 100°C, the reaction starts, the liquid is collected in the gas condenser, and the catalyst solution separated by the flash tank enters the liquid outlet for recycling. After 1 hour, the system entered a steady state. In the separated liquid mixture, the DEC content was 21%. The crude product was separated into the next section to obtain a DEC content of 99.7%. After 15 hours of operation, the catalyst yield was 0.9g DEC / gcat.h, after running for 100 hours, the yield is 0.7 g DEC / gcat.h, an...

Embodiment 2

[0038] 8 kilograms of industrial-grade copper bromide, 110 kilograms of methanol, and 4 kilograms of industrial-grade quinoline are loaded into the reactor, and 10 L of ethylene carbonate is added, and the reaction is started according to the method described in Example 1. At 110 ° C, 3.0 MPa, it enters normal Reaction, after 1 hour, the DMC content in the crude product is 17%, after running for 10 hours, the catalyst yield is 0.6g DMC / gcat.h, after running for 100 hours, the productive rate is 0.7g DMC / gcat.h, after running for 200 hours , yield 0.65 g DMC / gcat.h.

Embodiment 3

[0040] 8 kilograms of industrial-grade copper bromide, 4 kilograms of industrial-grade 4-methylquinoline are packed into the reactor, 10 L of propylene carbonate is added, and the reaction is started according to the method described in Example 1. At 110 ° C, 3.0 MPa, the raw material is controlled The gas feed ratio is 3:1, and it enters the normal reaction. After 1 hour, the DEC content in the crude product is 15%. After running for 10 hours, the catalyst yield is 0.4g DEC / gcat.h. After running for 100 hours, the yield is 0.6 g DEC / gcat.h, yield 0.53 g DEC / gcat.h after 200 hours of operation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com