A kind of preparation method of fluidized bed catalyst

A catalyst and fluidized bed technology, which is applied in the field of fluidized bed catalyst preparation, can solve the problems of large influence of catalyst pore structure, high cost of alumina fiber, small pore volume of alumina fiber, etc., so as to increase the number of contacts between particles, The effect of grain integrity and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

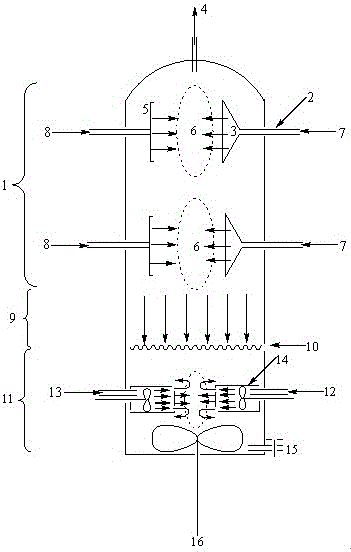

Method used

Image

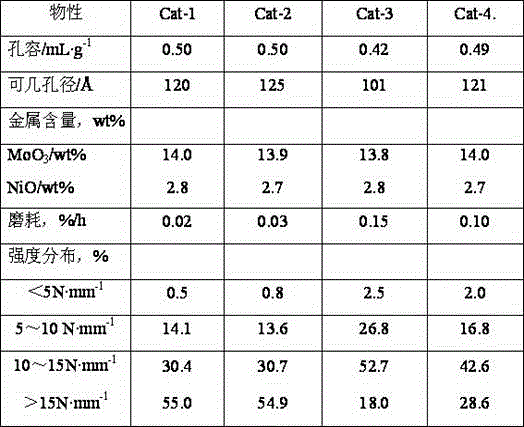

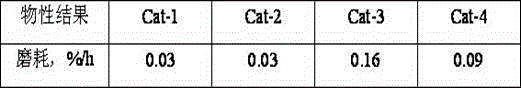

Examples

Embodiment 1

[0050] This example introduces the preparation method of Mo, Ni, P original solution. In this example, only one original solution of Mo, Ni, and P with one concentration and ratio is prepared, and solutions with other ratios and concentrations can be prepared according to the method introduced.

[0051] Take 386g of molybdenum oxide and 123g of basic nickel carbonate into a multi-necked flask, add a certain amount of deionized water, stir until the substance in the bottle is slurry, then slowly add 86g of phosphoric acid, and then heat slowly after the initial reaction , keep the solution temperature at 90° C. to 110° C. for 1 h to 3 h. After stopping the heating, filter the obtained solution while it is hot, and after filtering out some insoluble impurities, a clear dark green original solution is obtained. The solution composition is MoO 3 : 69.27g / 100ml; NiO: 12.49g / 100ml; P: 4.10g / 100ml.

Embodiment 2

[0053] Add bottom water to the bottom of the gas-liquid impingement flow reactor and heat it to 90°C; start the impingement flow reactor and adjust the propeller speed to 1000 r / min. Adjust the impact direction of the two acceleration tubes to be horizontal, start the accelerator, inject the alkali metal aluminate aqueous solution with a concentration of 30g / 100mL at a flow rate of 15L / h from the feed port I, and atomize the liquid through the pressure atomization nozzle The CO injected by the accelerator tube at the air inlet level with it at a flow rate of 10L / h 2 Collide with each other, react for 1.0h, stop injecting gas and liquid and the bottom agitator; at the same time, add sodium metaaluminate solution and aluminum sulfate solution continuously at 0.6L / min at the feed port II and III at both ends of the impact flow reactor, Adjust the pH value to 7.5, and after 15 minutes of neutralization reaction, stop feeding at the feed port; raise the temperature at the bottom to...

Embodiment 3

[0056] Add bottom water to the bottom of the gas-liquid impinging flow reactor and heat it to 80°C; start the impinging flow reactor and adjust the propeller speed to 1500 r / min. Adjust the impact direction of the two acceleration tubes to be horizontal, start the accelerator, inject the alkali metal aluminate aqueous solution with a concentration of 25g / 100mL at a flow rate of 10L / h from the feed port I, and atomize the liquid through the pressure atomization nozzle The CO injected by the accelerator tube at the air inlet level with it at a flow rate of 10L / h 2 Collide with each other, react for 1.0h, stop injecting gas and liquid and the bottom stirrer; at the same time, add sodium metaaluminate solution and aluminum sulfate solution continuously at 0.8L / min at the feed port II and III at both ends of the impact flow reactor, Adjust the pH value to 7.0, and after 10 minutes of neutralization reaction, stop feeding at the feed inlet; raise the temperature at the bottom to 120...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com