Contact agent for efficiently processing low-quality heavy oil and use method of contact agent

A low-quality heavy oil and contact agent technology, which is applied in the direction of gasification process, hydrocarbon oil treatment, hydrocarbon oil cracking, etc., can solve the problems of high wax oil content, low yield of light oil, high yield of dry gas and coke, and achieve Easy to recycle, simple process, and the effect of reducing SOX emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

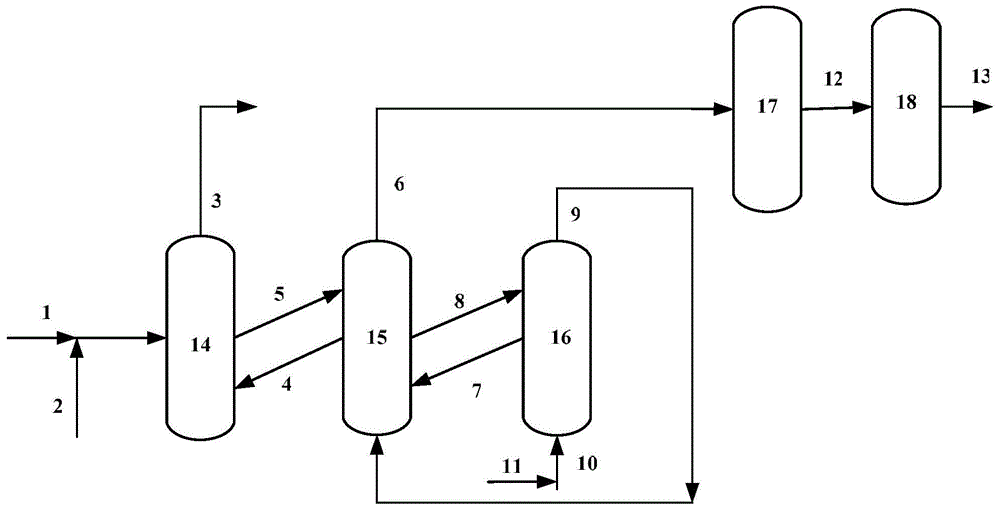

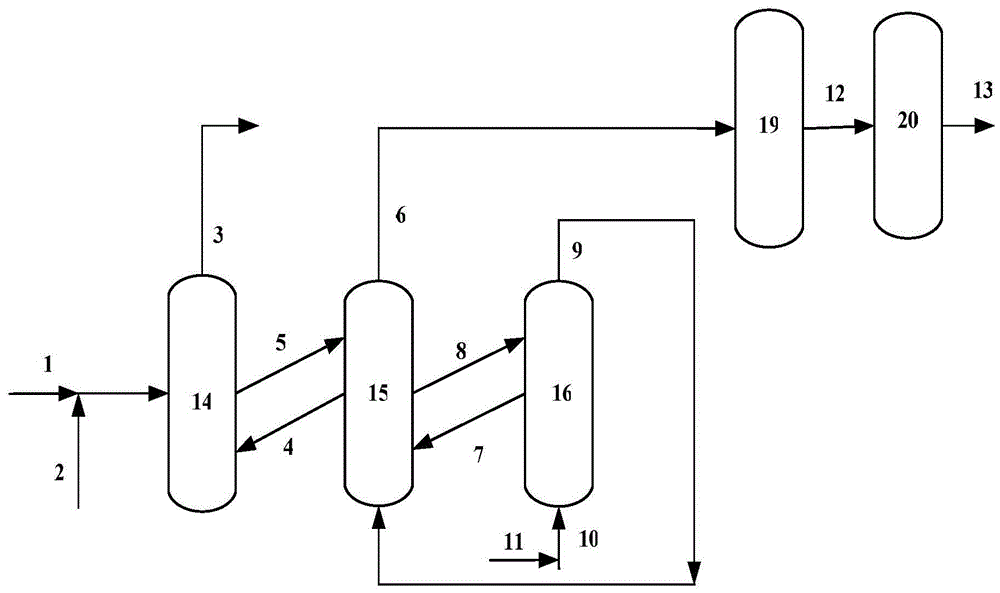

Method used

Image

Examples

Embodiment 1

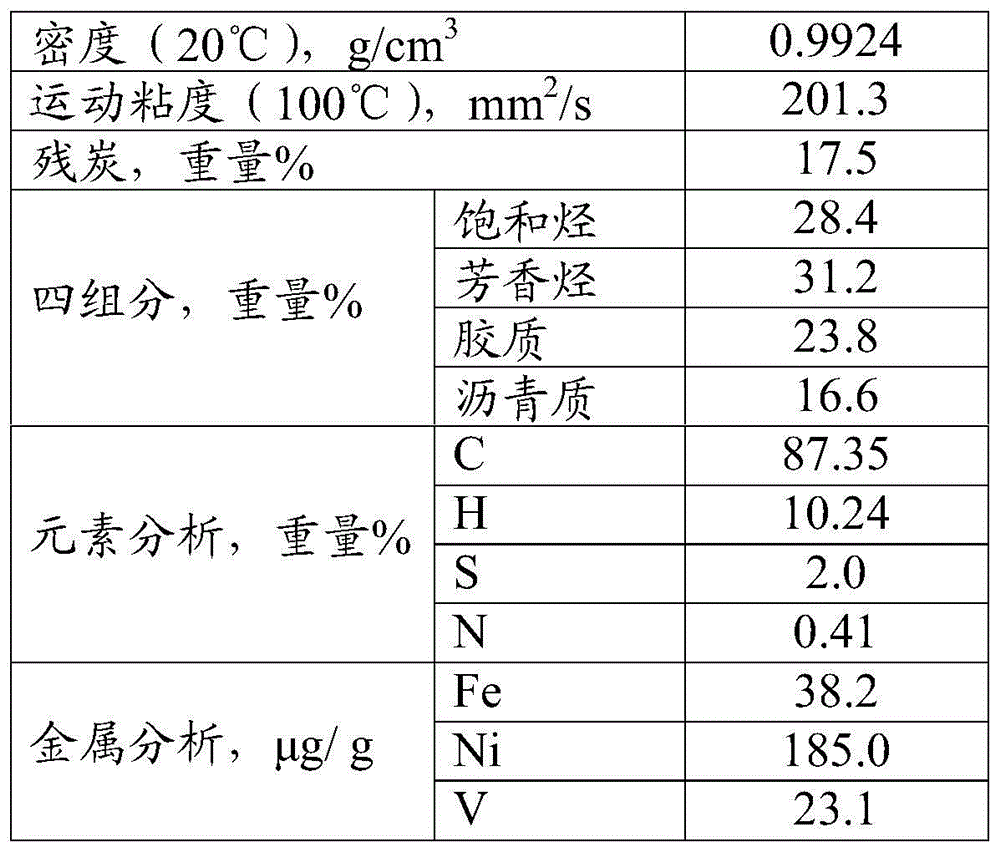

[0047] Inferior residual oil and water are preheated at a mass ratio of 1:0.01 and then enter the contact cracking unit. The contact agent is a mixture containing 90% by weight of CRC-1 catalytic cracking catalyst and 10% by weight of MFC-2. The process conditions are: The reaction temperature is 490°C, the agent-to-oil ratio is 10, the water-to-oil ratio is 0.2, and the gas phase residence time is 2.0s. The distribution of the obtained products is shown in Table 2. The spent agent obtained after the contact cracking reaction enters the heater, exchanges heat with the contact agent and gasification gas from the gasifier, heats up to 650°C, and then enters the gasifier for oxygen-lean regeneration. The process conditions are: dense phase bed The temperature in the chamber is 730°C, the linear velocity in the dense-phase bed is 0.25m / s, the gas residence time is 30 seconds, the oxygen molar content in the gasification agent is 20%, and the water molar content is 80%. The composit...

Embodiment 2

[0051] Inferior residual oil and water are heated to 380°C through a heating furnace at a mass ratio of 1:0.08, and enter the contact cracking unit. The contact agent is a mixture containing 10% by weight of MFC-1 and 90% by weight of MFC-2. The process conditions are: Cracking temperature 530°C, space velocity 20h -1 , the agent-oil ratio is 7, the water-oil ratio is 0.25, the total pressure (gauge pressure) is 1.0MPa, the hydrogen partial pressure is 0.3MPa, and the hydrogen-oil ratio is 100m 3 / m 3 , the resulting product distribution is shown in Table 2. The spent agent obtained after the contact cracking reaction enters the heater, exchanges heat with the contact agent and gasification gas from the gasifier, and then enters the gasifier after heating up to 630°C. The process conditions are: the temperature in the dense-phase bed is 920 ℃, linear velocity in dense bed 0.33m / s, gas residence time 50 seconds, oxygen content 20%, CO 2 The molar content is 80%, and the comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com