Preparation method of porous micro-nano PET fibers

A micro-nano, fiber technology, applied in the field of textiles, can solve problems such as less research, achieve the effect of increasing porosity and specific surface area, simple and easy method, and improving interception effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

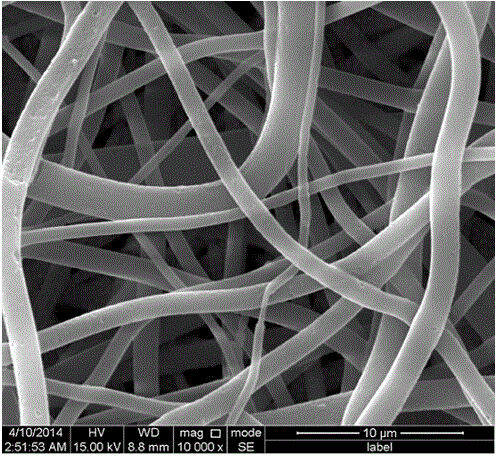

[0018] The PET slices and polyvinyl alcohol (PVA) were first dried in a vacuum oven. Measure 20 mL of a mixed solvent of trifluoroacetic acid and methylene chloride with a volume ratio of 1:1 and a mass of 15.40 g and 13.30 g, respectively, in an iodine measuring bottle. Weigh 4.68 g and 0.77 g of PET and PVA, respectively, and make a mixed solution with a solution concentration of 16 wt%. Place on a magnetic stirrer and stir at room temperature for 9 h to obtain a homogeneous mixed solution. The composite fibers were prepared by electrospinning. The preparation conditions were as follows: the receiving distance was 16 cm, the spinning voltage was 20-25 kV, and the advancing speed was 0.001 mm / s. The prepared composite fiber membrane was extracted in distilled water at about 70 °C to a constant weight of the sample, rinsed with distilled water several times, dried naturally and then dried in a vacuum oven at 50 °C for 24 h to obtain micro-nano PET fibers with a porous structu...

Embodiment 2

[0021] The PET slices and polyethylene glycol (PEG) were first dried in a vacuum oven. Measure 20 mL of a mixed solvent of trifluoroacetic acid and dichloromethane with a volume ratio of 3:1 and a mass of 23.10 g and 6.65 g, respectively, in an iodine measuring bottle. 2.42 g of PET and PEG were weighed to prepare a mixed solution with a solution concentration of 14 wt%. Place on a magnetic stirrer and stir at room temperature for 6 h to obtain a homogeneous mixed solution. The composite fibers were prepared by electrospinning. The preparation conditions were as follows: the receiving distance was 16 cm, the spinning voltage was 20-25 kV, and the advancing speed was 0.001 mm / s. The prepared composite fiber membrane was extracted in distilled water at about 70 °C to a constant weight of the sample, rinsed with distilled water several times, dried naturally and then dried in a vacuum oven at 50 °C for 24 h to obtain micro-nano PET fibers with a porous structure. .

Embodiment 3

[0023] Dry the PET slices and polyvinylpyrrolidone (PVP) in a vacuum oven first. Measure 20 mL of a mixed solvent of trifluoroacetic acid and dichloromethane with a volume ratio of 4:1 and a mass of 24.64 g and 5.32 g, respectively, in an iodine measuring bottle. Weigh 3.02 g and 0.31 g of PET and PVP, respectively, and make a mixed solution with a solution concentration of 10 wt%. Place on a magnetic stirrer and stir at room temperature for 7 h to obtain a homogeneous mixed solution. The composite fibers were prepared by electrospinning. The preparation conditions were as follows: the receiving distance was 16 cm, the spinning voltage was 20-25 kV, and the advancing speed was 0.001 mm / s. The prepared composite fiber membrane was extracted in distilled water at about 70 °C to a constant weight of the sample, rinsed with distilled water several times, dried naturally and then dried in a vacuum oven at 50 °C for 24 h to obtain micro-nano PET fibers with a porous structure. . ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com