Material capable of enriching and separating uranium in aqueous solution and its preparation method

An aqueous solution and enrichment technology, applied in chemical instruments and methods, improvement of process efficiency, other chemical processes, etc., can solve the problems of easy powder agglomeration, difficult recovery, and difficult to process and shape, and achieve mild desorption conditions and simple methods. Ease of operation and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is illustrated below in conjunction with examples.

[0024] One, the preparation of material of the present invention

[0025] Under vigorous stirring, 0.3M 25mL H 3 PO 4 Add 50mL of 0.25M Ca(OH) dropwise at a rate of 1mL / min 2 , the reaction was maintained at 55 ° C, after the addition of phosphoric acid was completed, the N 2 After a period of time, add 1±0.0010g (1:1) or 0.5±0.0010g (2:1) of acrylic acid, and then add 0.2g of cross-linking agent (N,N-methylene acrylamide (TEMED)), the increase The temperature is controlled at about 80°C. After the temperature is reached, add 0.5 mg of initiator (potassium persulfate) heated and dissolved in a small beaker, and continue under N 2 The reaction was heated under protection for a total reaction time of 8 hours. After the reaction stopped, the product was centrifuged, washed several times with deionized water, centrifuged and dried.

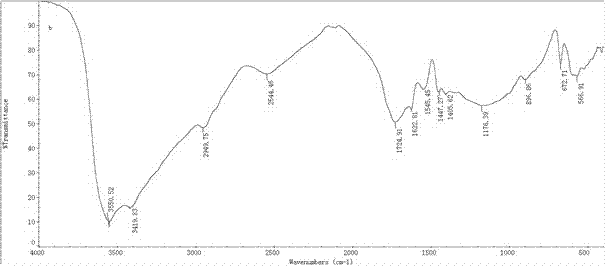

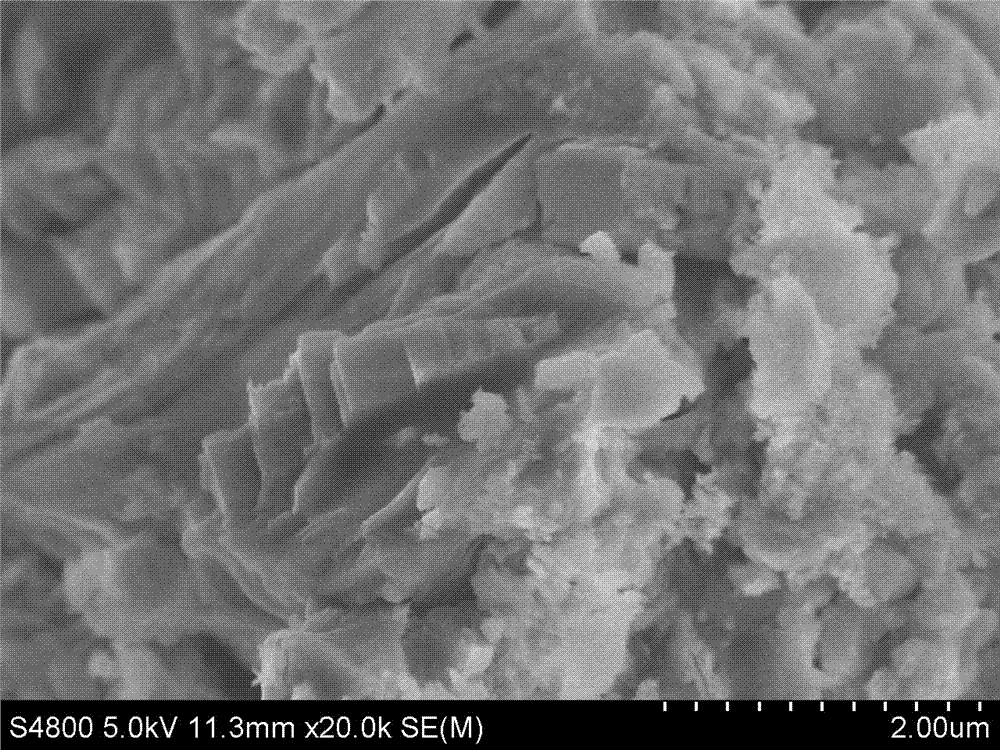

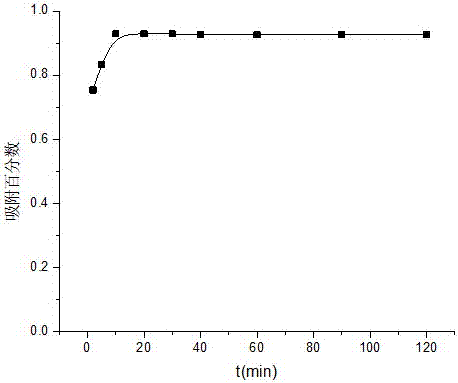

[0026] Characterization of the prepared material: IR infrare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com