Preparation method of superhydrophilic transparent anti-fog coating

An anti-fog coating and super-hydrophilic technology, applied in the coating and other directions, can solve the problems of mechanical friction resistance, easy peeling off of the coating film, and short service life, and achieve good water resistance, easy operation, and short production cycle. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

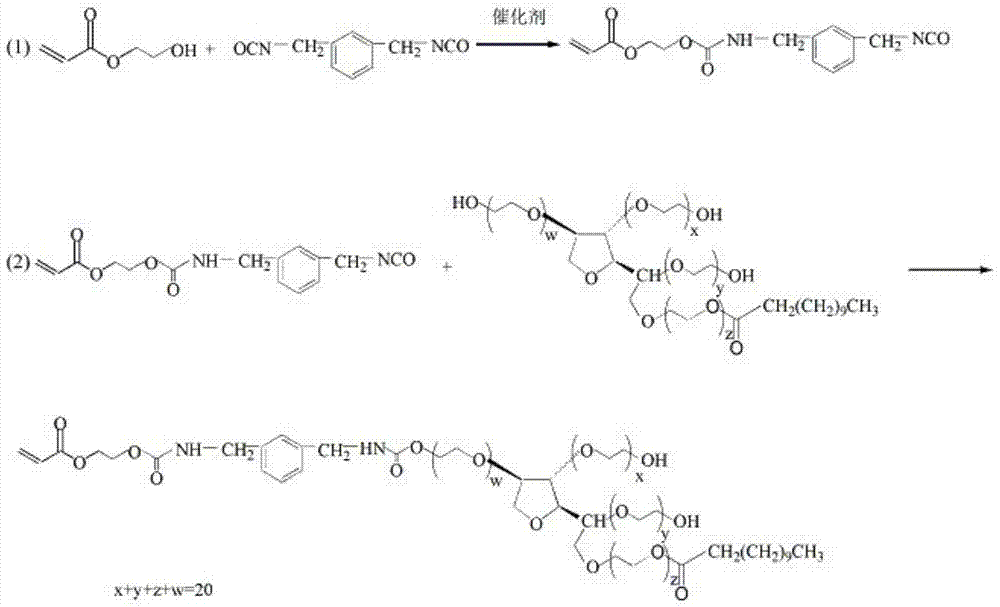

[0025] A kind of preparation method of superhydrophilic transparent anti-fog coating, it comprises the following steps:

[0026] (1), prepare polyurethane prepolymer:

[0027] Add diisocyanic acid monomer, hydroxy acrylate and organic solvent A into the reaction vessel, wherein the molar ratio of diisocyanic acid monomer to hydroxy acrylate is 0.7:1-1:1, hydroxy acrylate and organic solvent A The molar ratio is 3:7-1:1, then dibutyltin dilaurate is added as a catalyst, the amount of catalyst is 0.1-1% of the mass of diisocyanate monomer, and the above mixture is reacted at 50-70°C for 2 -4h, obtain polyurethane prepolymer;

[0028] (2), prepare the superhydrophilic prepolymer of polysorbate modification:

[0029] Polysorbate is dissolved with organic solvent B and added to the polyurethane prepolymer prepared above, wherein, in the mixed solution of polysorbate and organic solvent B, the mass concentration of polysorbate is 50-80%, polysorbate The molar ratio of sorbate to ...

Embodiment 1

[0034] Embodiment 1: a kind of preparation method of superhydrophilic transparent anti-fog coating, it comprises the following steps:

[0035] (1), prepare polyurethane prepolymer:

[0036] In a 250ml four-neck bottle, mix 4,4,-dicyclohexylmethyl diisocyanate monomer and hydroxymethyl methacrylate into the organic solvent ethylene glycol methyl ether, in which 4,4,-dicyclohexylmethyl The molar ratio of base diisocyanate monomer and methylol methacrylate is 0.7:1, then add catalyst dibutyltin dilaurate, the consumption of dibutyltin dilaurate is 0.1% of the quality of methylol methacrylate, methyl The molar ratio of hydroxymethyl acrylate to the organic solvent ethylene glycol methyl ether is 3:7, and the above mixture is reacted at 60° C. for 2 hours to obtain a polyurethane prepolymer;

[0037] (2), prepare the superhydrophilic prepolymer of polysorbate modification:

[0038] Polysorbate 80 is dissolved with organic solvent ethylene glycol methyl ether and added in the poly...

Embodiment 2

[0042] Embodiment 2: a kind of preparation method of superhydrophilic transparent anti-fog coating, it comprises the following steps:

[0043] (1), prepare polyurethane prepolymer:

[0044] In a 250ml four-necked bottle, mix 1,6-hexamethylene diisocyanate monomer and hydroxybutyl methacrylate into the organic solvent cyclohexane, wherein 1,6-hexamethylene diisocyanate monomer and hydroxybutyl methacrylate The molar ratio is 0.8:1, then add catalyst dibutyltin dilaurate, the consumption of dibutyltin dilaurate is 0.5% of hydroxybutyl methacrylate quality, the mole of hydroxybutyl methacrylate and organic solvent cyclohexane The ratio is 4:6, and the above mixture is reacted at 50°C for 3h to obtain a polyurethane prepolymer;

[0045] (2), prepare the superhydrophilic prepolymer of polysorbate modification:

[0046] Polysorbate 40 is dissolved with organic solvent acetone and added to the above polyurethane prepolymer, wherein the mass concentration of polysorbate in solvent a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com